Rice straw particle making technology

A technology of rice straw and production process, which is applied in food processing, animal feed molding or processing, food science and other directions to achieve the effect of reducing residual amount, less protein content and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

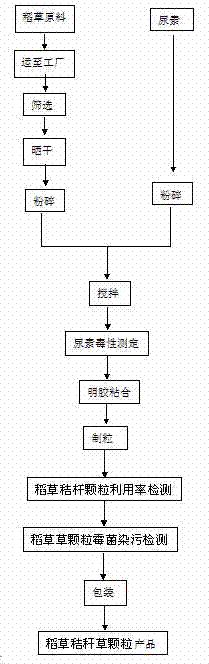

[0017] Such as figure 1 Shown, technique of the present invention is:

[0018] First, through screening the straw, dry the straw straw without mildew and no qualitative change, and crush it into grass powder with a grass powder grinder, and the number of crushed mesh is 60 mesh;

[0019] Second, the determination of urea toxicity: pulverize urea particles with a pulverizer, evenly sprinkle them in the pulverized grass powder, and stir to make the final concentration of urea be about 1%, and the final concentration of urea should not exceed 3% of the total weight. These grass powders were first fed to 50 bred cows, and 18 blood indicators were measured through blood index analysis, and no abnormalities were found in the results. Then these grass powders were fed to 30 cows, and 18 blood indicators were measured, and no abnormalities were found. These experiments proved that the urea added in the grass powder produced did not cause adverse effects on the cows;

[0020] Thirdly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com