Air purification technology-scrubbing

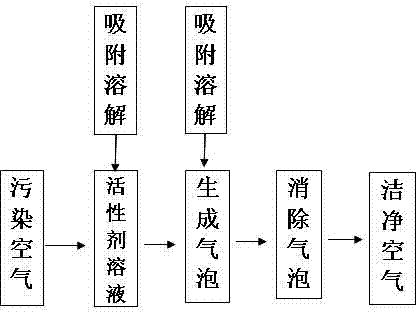

A technology for air purification and gas scrubbing, which is applied in the field of gas scrubbing technology to achieve the effects of simple process, good effect, and good adsorption and dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation

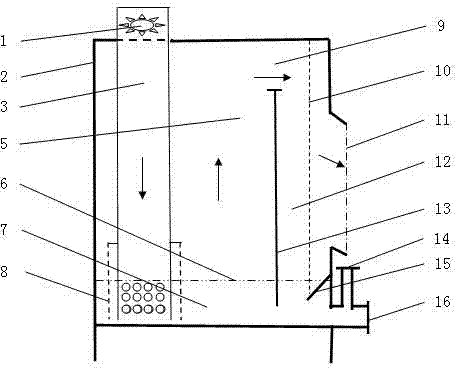

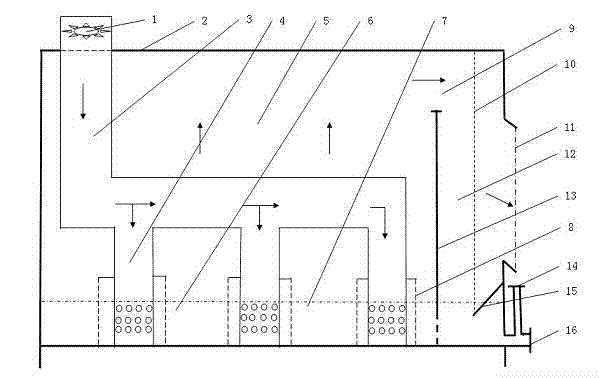

[0023] A purifier specifically designed using this scrubbing process will be described in detail below. Such as figure 1 shown.

[0024] First introduce the structure of the purifier, (2) is the purifier box, the bottom of the box is a water tank, and the solution depth is 30cm. Install the air inlet (3) vertically on one side of the box, the upper part of the air inlet is tightly connected to the box, the lower part is immersed in the surfactant solution (7), and 1 to 3 mesh lifters are placed around the lower part of the air inlet Bubbler (8), the lower part of the bubbler is submerged in the solution, and the upper part is exposed to the liquid surface by 10cm. The upper port of the air inlet is connected with the outlet of the blower fan (1). The space above the liquid level (6) is a bubble chamber (5), and the volume of the bubble chamber is about 0.5 liters. The partition plate (13) separates the bubble chamber from the defoam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com