Welding process of plunger assembly of hydraulic buffer

A hydraulic buffer and welding process technology, applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of high labor intensity of operators, uneven welding seam, low welding efficiency, etc., and achieve beautiful appearance and uniform welding seam , the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

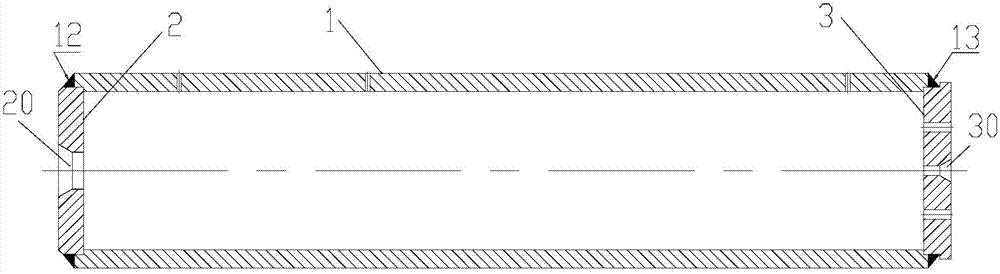

[0023] see figure 1 , The plunger assembly of the hydraulic buffer is composed of a plunger 1, a base plate 3, and a seat plate 2 welded together. The base plate 3 and the seat plate 2 respectively have a central hole 30, 20 coaxial with the plunger 1.

[0024] The welding process of the plunger assembly of the hydraulic buffer of the present invention is operated by a robot holding a welding machine on the welding tool. The welding tooling includes left thimble, right thimble and auxiliary support. The left thimble is installed on a tailstock that can move axially along the guide rail to adapt to the diversity of product lengths. The left thimble is a flexible thimble. The guide rail is equipped with a guide rail brake system. In order to lock the position of the tailstock after adjusting the thimble at the left end. The thimble at the right end is installed on the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com