A Submerged Arc Welding Process for Welding Steel Plates with a Thickness Greater Than 40mm Without Root Cleaning

A submerged arc welding technology that does not need root cleaning. It is applied in welding equipment, arc welding equipment, manufacturing tools, etc. It can solve the problems of impenetrable welding, sensitivity to assembly and centering precision, easy side deviation of the arc, etc., and achieve weld formation Good, insensitive to center precision, and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A submerged arc welding process that does not need root cleaning for welding steel plates with a thickness greater than 40mm:

[0031] 1) Conditions for the use of base materials: steel plates produced by TMCP, with a thickness of 40mm and equal thickness butt welding;

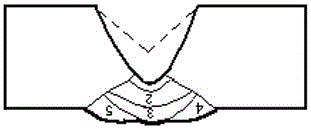

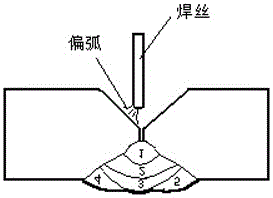

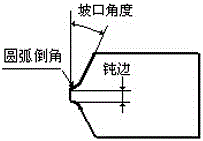

[0032] 2) Groove shape: Double Y-shaped arc chamfering, the blunt edge is 6mm, and the angle on one side is 25°; arc chamfering: one end of the arc is perpendicular to the blunt edge, and the other end is tangent to the edge of the bevel. The radius of the groove is 6mm; the front groove depth is 14mm, and the reverse groove depth is 20mm;

[0033] 3) Submerged arc welding wire with matching wire diameter of 3.0mm;

[0034] 4) Welding process parameters: The welding line energy of the first welding seam on the front side is ~18J / cm, and the welding line energy of the first welding seam on the back side is ~40J / cm without root cleaning, and the distance between the blunt edges of the two plates is contr...

Embodiment 2

[0037] A submerged arc welding process that does not need root cleaning for welding steel plates with a thickness greater than 40mm:

[0038] 1) Conditions for the use of base materials: steel plates produced by micro-alloying, with a thickness of 50 mm and equal thickness butt welding;

[0039] 2) Groove shape: Double Y-shaped arc chamfering, the blunt side is 5mm, and the one-sided angle is 22.5°; arc chamfering: one end of the arc is perpendicular to the blunt side, the other end is tangent to the bevel edge, and the arc The radius of the groove is 5mm; the front groove depth is 20mm, and the reverse groove depth is 25mm;

[0040] 3) Submerged arc welding wire with matching wire diameter of 4.0mm;

[0041] 4) Welding process parameters: The welding line energy of the first welding seam on the front side is ~20J / cm, and the welding line energy of the first welding seam on the back side is ~45J / cm without root cleaning, and the distance between the blunt edges of the two pla...

Embodiment 3

[0044] A submerged arc welding process that does not need root cleaning for welding steel plates with a thickness greater than 40mm:

[0045] 1) Conditions for the use of substrates: steel plates produced by microalloying, with a thickness of 60 mm and equal thickness butt welding;

[0046] 2) Groove shape: double Y-shaped arc chamfer, blunt side is 6mm, one-sided angle is 22.5°; arc chamfer: one end of the arc is perpendicular to the blunt edge, the other end is tangent to the bevel edge, The radius of the groove is 5mm; the front groove depth is 24mm, and the reverse groove depth is 30mm;

[0047] 3) Submerged arc welding wire with matching wire diameter of 4.0mm;

[0048] 4) Welding process parameters: The welding line energy of the first welding seam on the front is ~25J / cm, and the welding line energy of the first welding seam on the reverse side is ~50J / cm without root cleaning, and the distance between the blunt edges of the two plates is controlled. The upper and low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com