Composite base plate for drilling PCB (printed circuit board) and preparation method thereof

A technology of composite backing plate and substrate, applied in drilling/drilling equipment, chemical instruments and methods, manufacturing tools, etc., can solve the problems of high cost, ordinary melamine wood backing plate does not meet the requirements of high-precision drilling, etc. Achieve the effect of increasing hardness, meeting the requirements of small-diameter drilling, and improving the effect of chip removal and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The high-density fiberboard adopted in Example 1 has a hardness of 80hd, a density of 900kg / m3, and a thickness of 2.2mm.

[0034] Use a 1.5 cubic meter reaction tank to produce modified urea-formaldehyde resin. Melamine-modified urea-formaldehyde resin refers to adding melamine (melamine) to the synthetic raw material of urea-formaldehyde resin. The specific ratio of raw materials in parts by weight is as follows: 550 parts of formaldehyde, 25 parts of urotropine, 75 parts of melamine, 200 parts of urea, 200 parts of methanol, 50 parts of diethylene glycol, and 50 parts of water.

[0035] The specific preparation process is as follows: sequentially add urotropine, melamine and urea into a reaction kettle. Raise the temperature of the reactor to 75°C for reaction, then keep it warm for 60 minutes, add methanol, then raise the temperature to 73°C, and keep it warm for 2 hours, then add diethylene glycol solution, and pass water to cool down and discharge.

[0036] Utili...

Embodiment 2

[0044] The high-density fiberboard adopted in Example 2 has a hardness of 85hd, a density of 950kg / m3, and a thickness of 2mm.

[0045] Use a 1.5 cubic meter reaction tank to produce modified urea-formaldehyde resin. Melamine-modified urea-formaldehyde resin refers to adding melamine (melamine) to the synthetic raw material of urea-formaldehyde resin. Its specific raw material ratio is as follows: 600 parts of formaldehyde, 40 parts of urotropine, 100 parts of melamine, 150 parts of urea, 150 parts of methanol, 25 parts of diethylene glycol, and 25 parts of water.

[0046] The specific preparation process is as follows: sequentially add urotropine, melamine and urea into a reaction kettle. Raise the temperature of the reactor to 70°C for reaction, then keep it warm for 20 minutes, add methanol, then raise the temperature to 70°C, and keep it warm for 1 hour, then add diethylene glycol solution, and pass water to cool down and discharge.

[0047] Utilize the modified urea-formal...

Embodiment 3

[0052] The high-density fiberboard adopted in embodiment 3 has a hardness of 75hd, a density of 900kg / m3, and a thickness of 2.1mm.

[0053] Use a 1.5 cubic meter reaction tank to produce modified urea-formaldehyde resin. Melamine-modified urea-formaldehyde resin refers to adding melamine (melamine) to the synthetic raw material of urea-formaldehyde resin. The specific ratio of raw materials in parts by weight is as follows: 550 parts of formaldehyde, 26 parts of urotropine, 75 parts of melamine, 200 parts of urea, 200 parts of methanol, 50 parts of diethylene glycol, and 50 parts of water.

[0054] The specific preparation process is as follows: sequentially add urotropine, melamine and urea into a reaction kettle. Raise the temperature of the reactor to 73°C for reaction, then keep it warm for 30 minutes, add methanol, then raise the temperature to 70°C, and keep it warm for 1.5 hours, then add diethylene glycol solution, and pass water to cool down and discharge.

[0055] ...

PUM

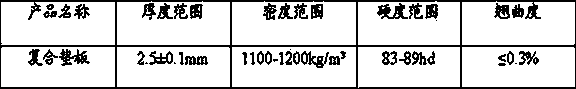

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com