Multifunctional automobile braking system

A car braking system and multi-functional technology, applied in the field of car braking systems, can solve problems such as inability to act immediately, high manufacturing cost, and complicated operation, so as to increase parking braking force, reduce driving difficulty, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

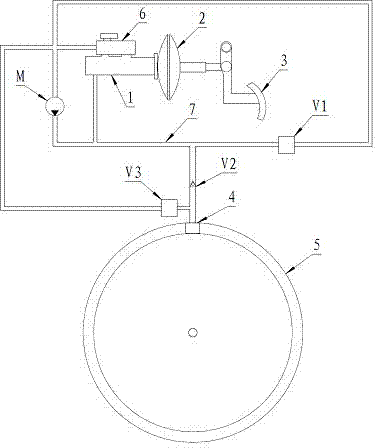

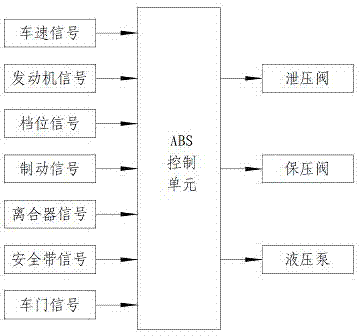

[0015] see figure 1 with figure 2 , the present invention includes a brake master cylinder 1, a vacuum booster pump 2, a brake pedal 3, a brake 4, a liquid storage tank 6, a brake pipe 7, a hydraulic pump M, a pressure relief valve V1, a pressure maintaining valve V2, a parking brake Automatic release valve V3, oil pipe and ABS control unit.

[0016] working principle:

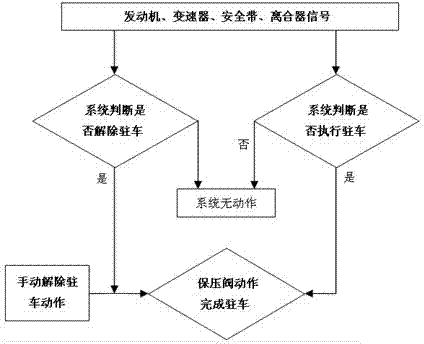

[0017] The system is based on the ABS system (or ESP system), in which all wheels are braked, and the braking force of each wheel can be independently controlled ( figure 1 Only one wheel is drawn in the figure, and the brakes of the rest of the wheels are the same), the parking brake system and the service brake share the same set of brake system, when the brake pedal is stepped on, the brake master cylinder 1 works, and the system Work in the service braking mode; when the system receives the parking signal, the hydraulic pump M starts to work; when the braking pressure of a wheel reaches the calculated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com