Electric heating system of high-temperature asphalt tank

A high-temperature asphalt, electric heating technology, applied in tank trucks, sustainable manufacturing/processing, biological packaging, etc., can solve problems such as fire hazards, explosion hazards, and reduced heat conversion rate, and achieve reduced use costs, no safety hazards, and thermal efficiency. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

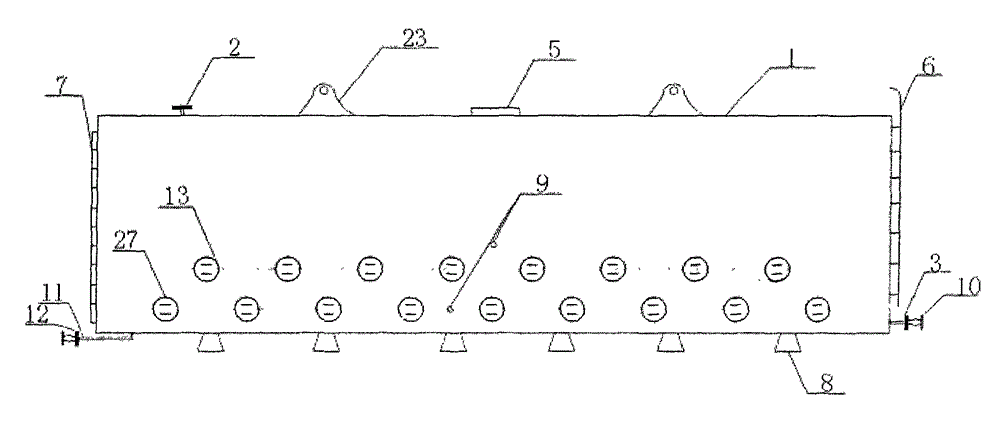

[0011] The invention includes three parts: a tank body part, a heating element part and an electrical control cabinet part.

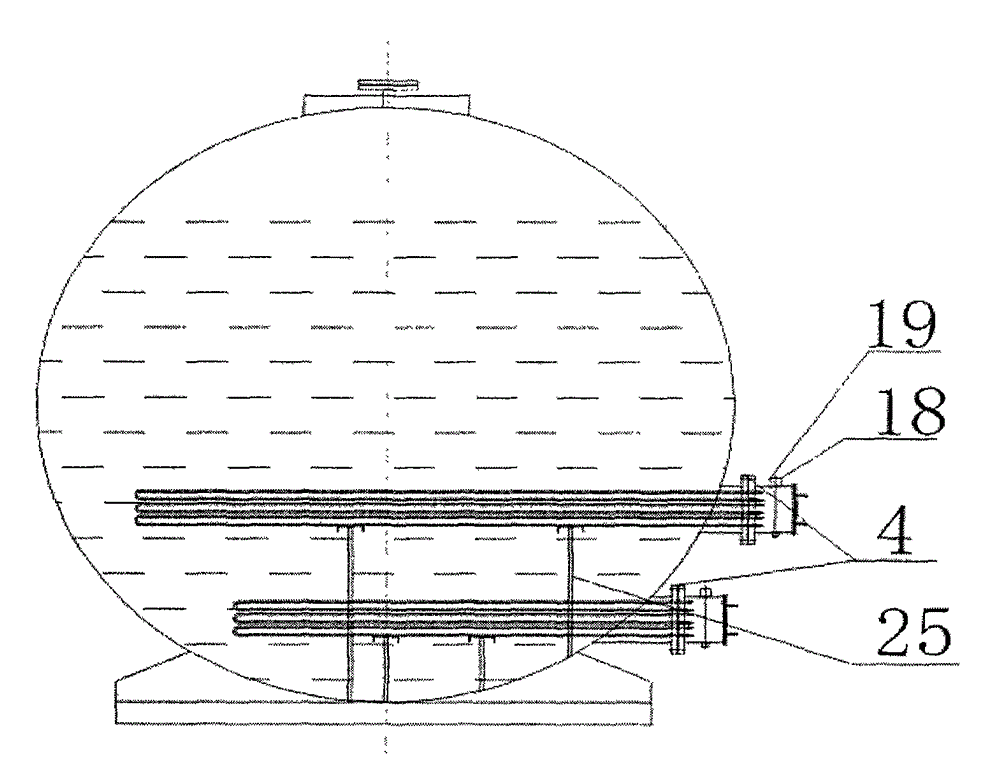

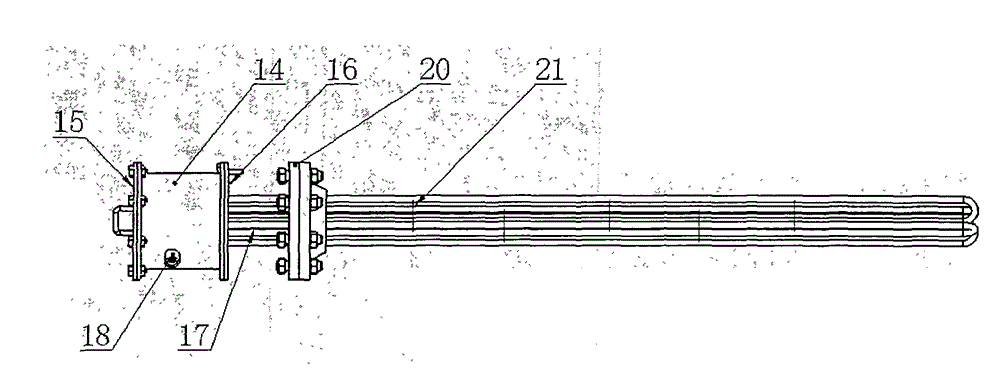

[0012] The heating element part has a variety of forms and can be used in a tubular bundled heating element structure, a rod-shaped heating element structure, and the like.

[0013] figure 1 The serial number and its functions: tank 1 stores asphalt; inlet flange 2 plays the role of inputting asphalt raw materials; outlet flange 3 plays the role of outputting heated asphalt; manhole 5; climbing ladder 6; liquid level gauge 7 monitors asphalt The function of liquid level; base 8; temperature detector 9 to monitor the temperature of asphalt; outlet valve 10; sewage pipe 11; sewage pipe flange 12; upper heating element 13; lifting lug 23; lower heating element 27.

[0014] figure 2 The serial number and its function: connecting flange 4 plays the role of pairing and connecting heater main flange 20; Unicom joint 18 and bell mouth 19 play the role of int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com