Fluidized bed reactor for preparing ammonia by virtue of pyrolysis of urea

A fluidized bed reactor and the technology of the reactor are applied in the field of flue gas denitrification, which can solve the problem that the catalyst and urea cannot be mixed well, the unfavorable urea pyrolysis reaction proceeds smoothly and effectively, and the catalyst utilization and recovery are not considered. problems, to achieve the effect of ensuring the pyrolysis conversion rate, promoting heat exchange and momentum exchange, and low device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing

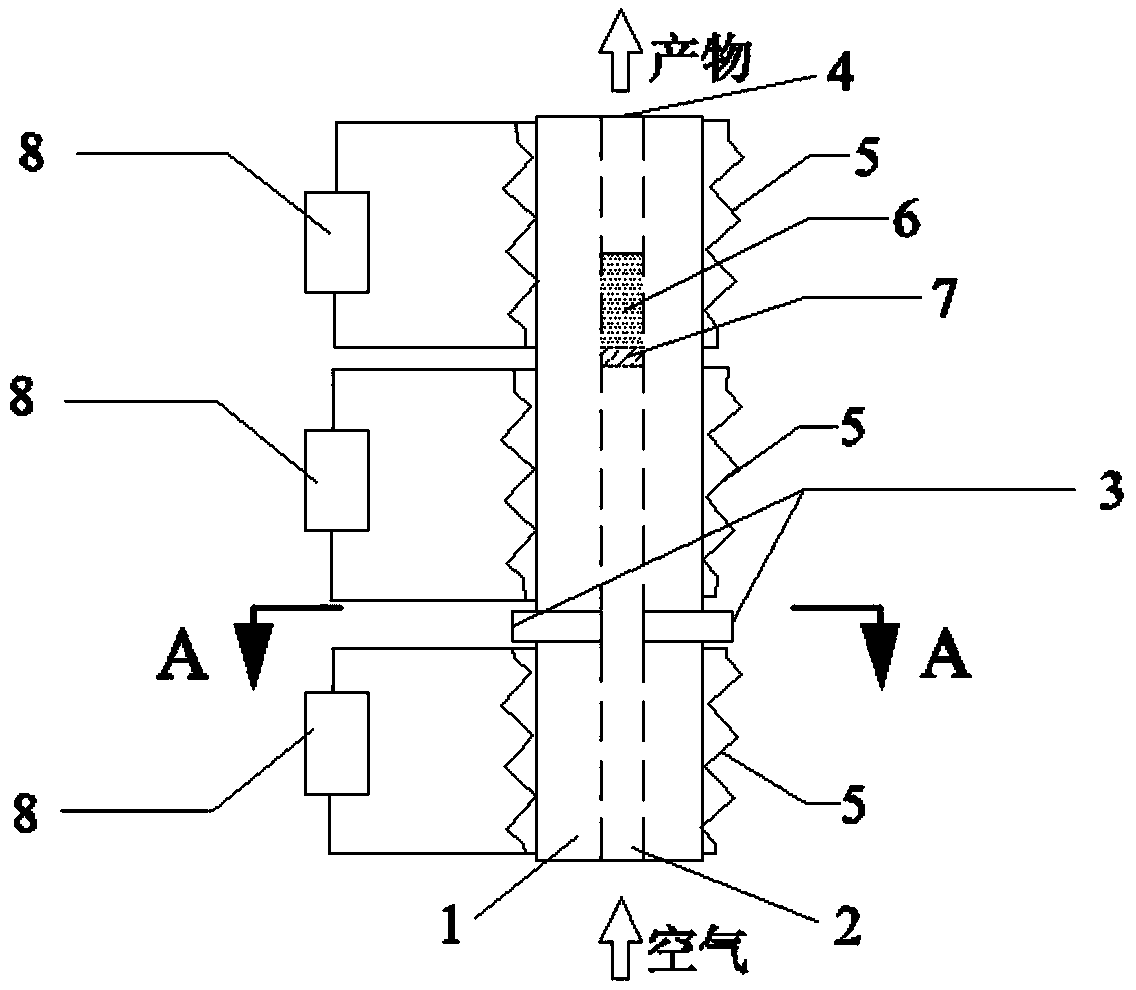

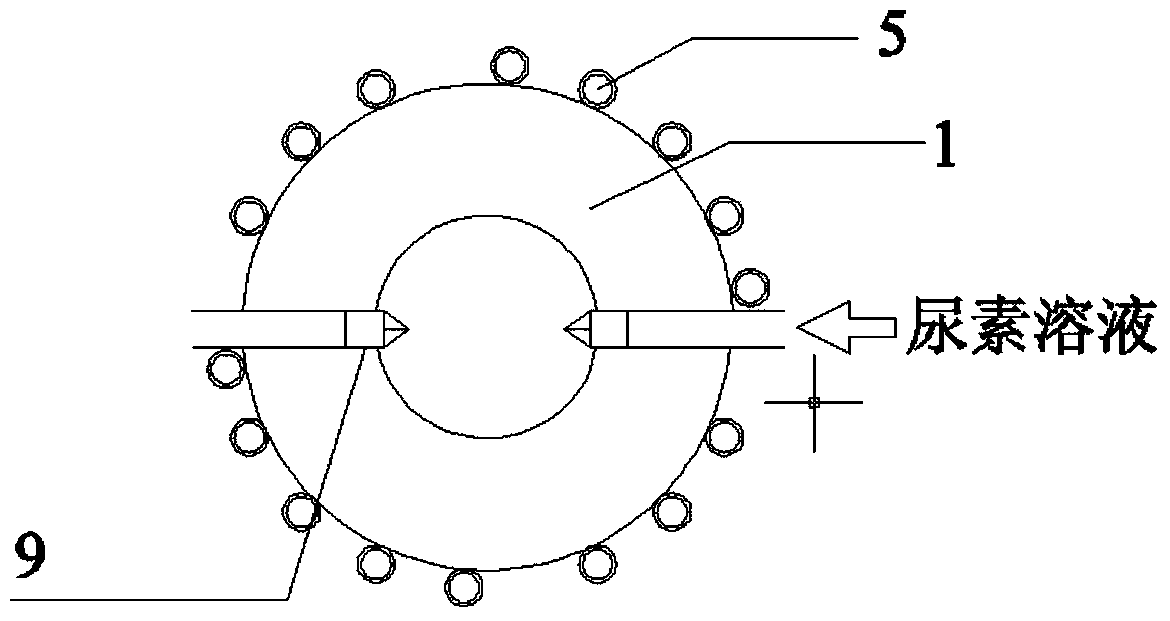

[0024] see figure 1 and figure 2 , the present invention comprises a cylindrical reactor body 1 made of heat-resistant steel, the lower part of the reactor body 1 is provided with a gas inlet 2 for feeding air or flue gas, and the upper part of the reactor body 1 is provided with a reaction product outlet 4, and the gas inlet 2 communicates with the reaction product outlet 4 to form a reaction cavity; the reaction cavity between the gas inlet 2 of the reactor body 1 and the reaction product outlet 4 is cylindrical, and the cross section of the reactor body 1 is Ring shape; the side of the reactor body 1 is provided with several solution inlets 3 for passing urea solution into the reactor body 1; the outside of the reactor body 1 is wrapped with several groups of heating resistance wires 5 from top to bottom. Exemplarily, two solution inlets 3 are evenly opened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com