Non-phosphorus corrosion and scale inhibitor for industrial cooling water system as well as preparation method and application thereof

A cooling water system, phosphorus-free corrosion inhibition technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problem of less application, achieve good effect and improve scale inhibition Limit upper limit, effect of improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

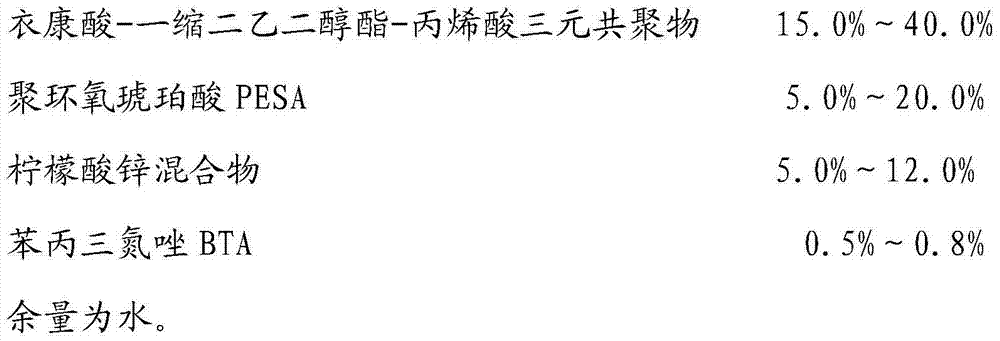

[0018] The preparation method of the itaconic acid-diethylene glycol ester-acrylic acid terpolymer comprises the following steps: in parts by weight, (1) 20-25 parts of itaconic acid, 0.2-0.5 part of diethylene glycol Ethylene glycol, 15-20 parts of mass percent concentration 40% NaOH solution and 10-15 parts of water are added to the reactor, stirred and dissolved; (2) 2-5 parts of mass percent concentration of 50% acrylic acid aqueous solution, as a A kind of dripping or feeding liquid; 5-15 parts of ammonium persulfate aqueous solution with a mass percentage concentration of 20% is used as another dropping or feeding liquid, and the two kinds of dropping or feeding liquid are continuously added to the above reaction at the same time (3) Control the reaction temperature to 95-105°C, drop or feed liquid reaction time is 1-1.5 hours, follow-up reaction time is 0.5-1 hour, after cooling, use mass percentage concentration 40 % NaOH solution to adjust the pH to be weakly acidic, ...

Embodiment 1

[0031] The synthesis of embodiment 1 itaconic acid-diethylene glycol ester-acrylic acid terpolymer

[0032] In parts by weight, (1) 20-25 parts of itaconic acid, 0.2-0.5 parts of diethylene glycol, 15-20 parts of 40% NaOH solution and 10-15 parts of water are added to the reactor (2) 2-5 parts of 50% mass percentage concentration of acrylic acid aqueous solution as a kind of dripping or feeding solution; 5-15 parts of 20% mass percentage concentration of ammonium persulfate aqueous solution as Another kind of dripping or feeding liquid, two kinds of dropping or feeding liquids are continuously added to the above reactor at the same time to carry out polymerization reaction; The time is 1-1.5 hours, and the subsequent reaction time is 0.5-1 hours. After cooling, adjust pH to weak acidity with 40% NaOH solution in mass percentage concentration, and obtain brown red or sauce brown transparent viscous liquid which is itaconic acid-diethylene glycol ester-acrylic acid terpolymer. ...

Embodiment 2

[0033] The configuration of embodiment 2 zinc citrate mixture

[0034] The required raw materials for the zinc citrate salt mixture are composed according to the following molar ratio: the molar ratio between zinc ions and citrate ligands is 1:1 to 1:2. Zinc ions are introduced into the composition in the form of zinc citrate trihydrate, and citrate is introduced in the composition in the form of citric acid or potassium citrate or sodium citrate or ammonium citrate. The materials were taken according to the following composition mass percentages, 62% of zinc citrate trihydrate and 38% of citric acid, to obtain a mixture of zinc citrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com