to co 2 Novel power cycle mixed working fluid as main component and system and method thereof

A mixed working medium and power cycle technology, applied in the field of power machinery, can solve problems such as non-condensation, and achieve the effects of low cycle pressure, reduced system cost, and good environmental friendliness

Active Publication Date: 2017-03-15

INST OF MECHANICS CHINESE ACAD OF SCI

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But due to CO 2 The critical temperature is 31°C, with CO 2 When used as a power cycle working fluid, it cannot be condensed by conventional cooling water

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment A1

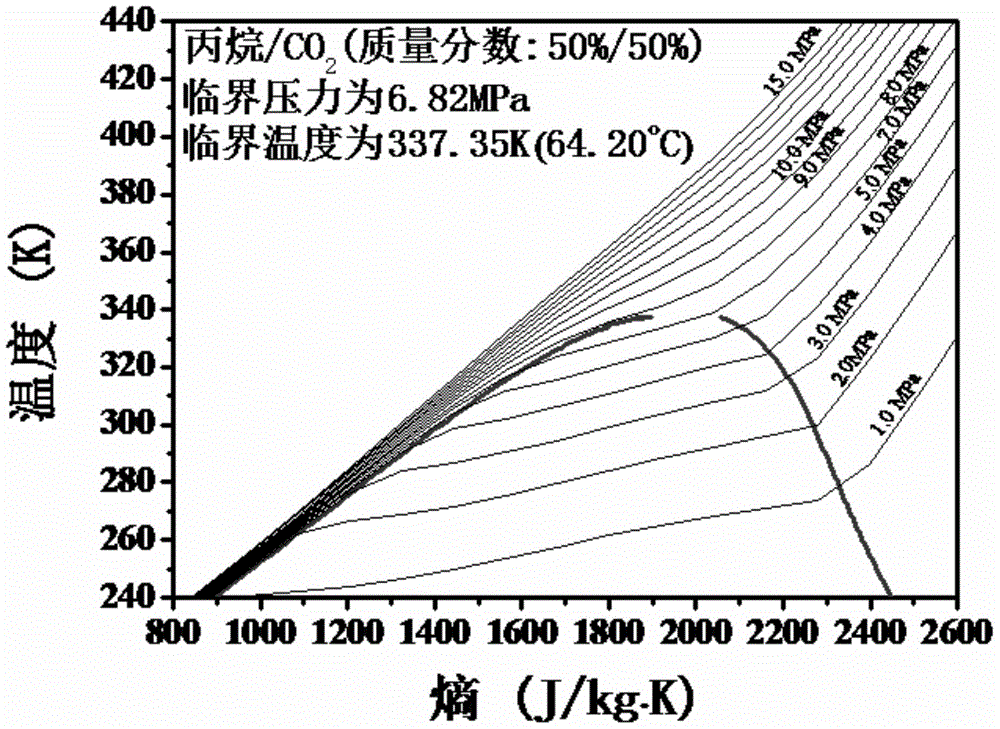

[0018] Embodiment A1: Propane and CO2 are physically mixed at a mass percentage of 50:50 when the system is filled with working fluid.

Embodiment B1

[0019] Embodiment B1: When the system is filled with working fluid, cyclopropane and CO 2 Physical mixing is carried out at a mass percentage of 10:90.

Embodiment B2

[0020] Embodiment B2: When the system is filled with working fluid, cyclopropane and CO 2 Physical mixing is carried out at a mass percentage of 20:80.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the technical field of power machinery, and discloses a novel power cycle mixed working medium taking CO2 as a main component, as well as a system and a method thereof. The mixed working medium is prepared by physically mixing CO2 with one of propane, cyclopropane, propyne, butane, iso-butane, cis-butene, trans-butene and cyclopentane at certain proportion. The mixed working medium takes CO2 as a main component and one of propane, cyclopropane, propyne, butane, iso-butane, cis-butene, trans-butene and cyclopentane as a second component, so that the mixed working medium can be condensed by the conventional cooling water, and the working medium also has lower flammability. When being used for exchanging heat with a heat source fluid, the mixed working medium has better temperature matching, and the cycling has higher efficiency.

Description

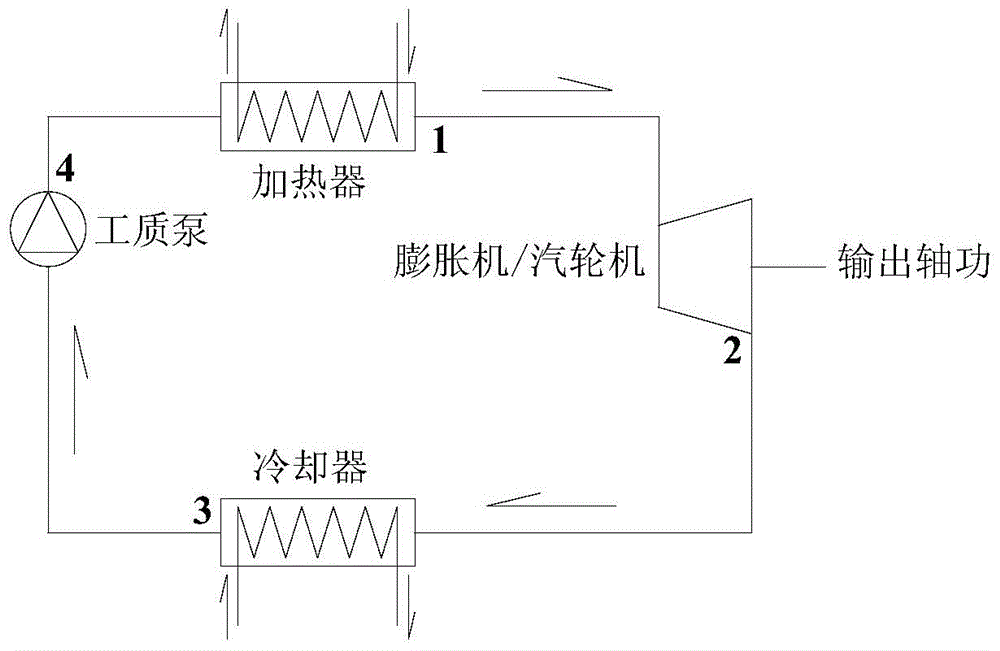

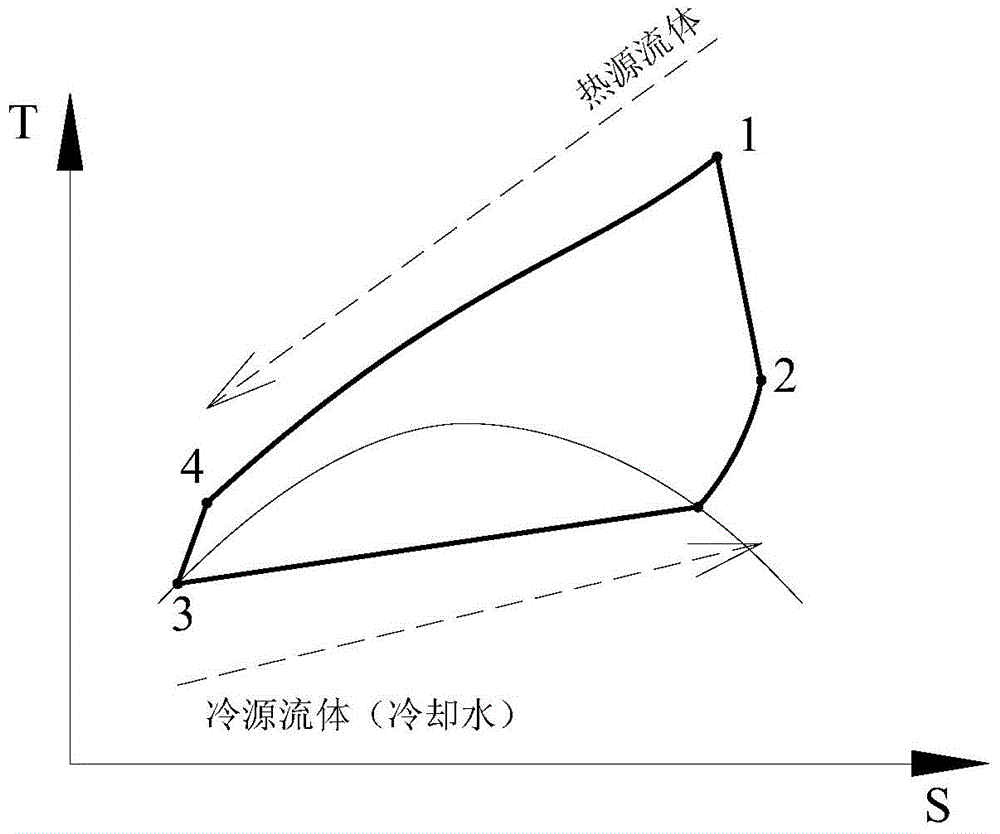

technical field [0001] The invention relates to the technical field of power machinery, in particular to a CO 2 It is a new type of power cycle mixed working fluid as the main component. Background technique [0002] Low-grade thermal energy exists widely, mainly including low-temperature geothermal energy, solar thermal energy, and industrial waste heat energy. Low-grade thermal energy reserves are huge, and if they can be used efficiently, they will produce huge economic and social benefits. The total amount of waste heat in the industrial field is huge. The total waste heat resources of metallurgy, chemical industry, coal and other industries account for 17%-67% of their fuel consumption, and the recyclable waste heat resources are about 60% of the total waste heat resources. [0003] Medium and high temperature heat energy can be recovered by using the traditional Rankine cycle with water as the working medium. When the heat energy below 350°C adopts the traditional Ra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K5/04

Inventor 潘利生魏小林李博史维秀

Owner INST OF MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com