Preparation method of high-toughness Q345 grade hot-rolled equal angle steel for iron tower

A technology of equal-edge angle steel and high toughness, which is applied in the field of preparation of high-toughness Q345 hot-rolled equal-edge angle steel for iron towers. It can solve problems such as lack of production capacity and hidden dangers in the safe operation of transmission towers in cold regions, and improve comprehensive mechanical properties. , cost improvement, and the effect of high impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

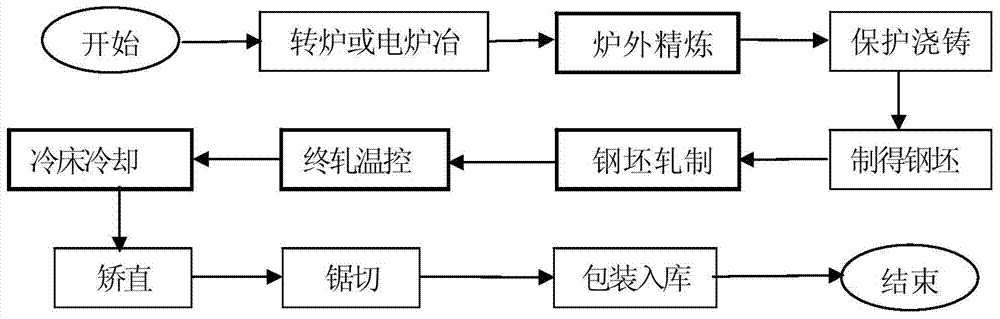

Method used

Image

Examples

Embodiment 1

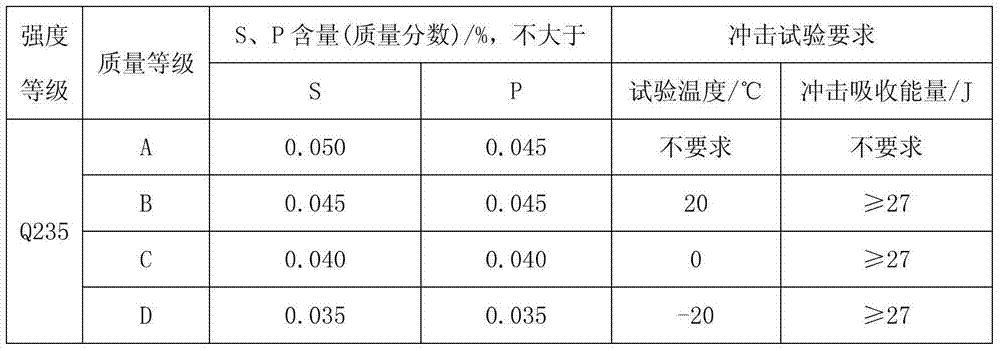

[0030] Q345 grade 18# angle steel is adopted, and the main technical and economic index requirements are: yield strength grade 345MPa; impact absorption energy: at -30°C, ≥34J; measured strength-to-yield ratio ≥1.20. The cost is not higher than 4% of the existing angle steel cost.

[0031] (1) Smelting and chemical composition: 100 tons of top-bottom combined blowing converter smelting, 100 tons of LF furnace refining, protective casting, carbon equivalent not exceeding 0.42%, the chemical composition of adding trace elements is as follows:

[0032] Table 4 Chemical composition (smelting, mass fraction) %

[0033] Carbon C

Silicon Si

Manganese Mn

Sulfur S

Vanadium V

Aluminum

0.18

0.38

1.32

0.016

0.010

0.02

0.018

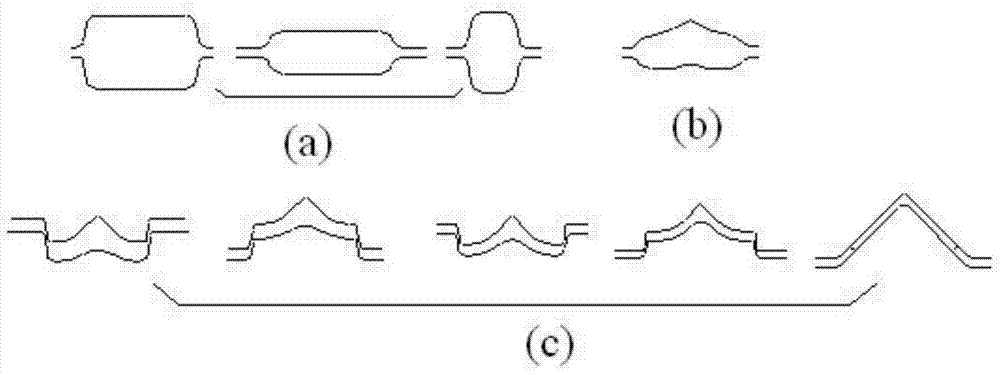

[0034] (2) Billet rolling: The billet is rolled in sequence according to the extension pass, splitting pass, and finishing pass. The average elongation coefficient of the finishing p...

Embodiment 2

[0040] Q345 grade 25# angle steel is adopted, and the main technical and economic index requirements are: yield strength grade 345MPa; impact absorption energy: at -30°C, ≥34J; measured strength-to-yield ratio ≥1.20. The cost is not higher than 4% of the existing angle steel cost.

[0041] (1) Smelting and chemical composition: 100 tons of top-bottom combined blowing converter smelting, 100 tons of LF furnace refining, protective casting, carbon equivalent not exceeding 0.42%, the chemical composition of adding trace elements is as follows:

[0042] Table 5 Chemical composition (smelting, mass fraction) %

[0043] Carbon C

Silicon Si

Manganese Mn

Sulfur S

Vanadium V

Aluminum

0.16

0.30

1.55

0.018

0.013

0.02

0.020

[0044] (2) Billet rolling: The billet is rolled in sequence according to the extension pass, splitting pass, and finishing pass. The average elongation coefficient of the finishing p...

Embodiment 3

[0050] Q345 grade 16# angle steel is adopted, and the main technical and economic index requirements are: yield strength grade 345MPa; impact absorption energy: at -30°C, ≥34J; measured strength-to-yield ratio ≥1.20. The cost is not higher than 4% of the existing angle steel cost.

[0051] (1) Smelting and chemical composition: 100 tons of top-bottom combined blowing converter smelting, 100 tons of LF furnace refining, protective casting, carbon equivalent not exceeding 0.42%, and the chemical composition of adding trace alloy elements are as follows:

[0052] Table 6 Chemical composition (smelting, mass fraction) %

[0053] Carbon C

Silicon Si

Manganese Mn

Sulfur S

Vanadium V

Aluminum

0.14

0.27

1.70

0.018

0.013

/

0.022

[0054] (2) Billet rolling: The billet is rolled in sequence according to the extension pass, splitting pass, and finishing pass. The average elongation coefficient of the fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact absorption energy | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com