Composite crucible, preparation method thereof and method for bismuth germanate crystal growth using the crucible

A composite crucible, bismuth germanate technology, applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of complex platinum processing and purification process, increase the production cost of BGO single crystal, etc., to save the use of platinum and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

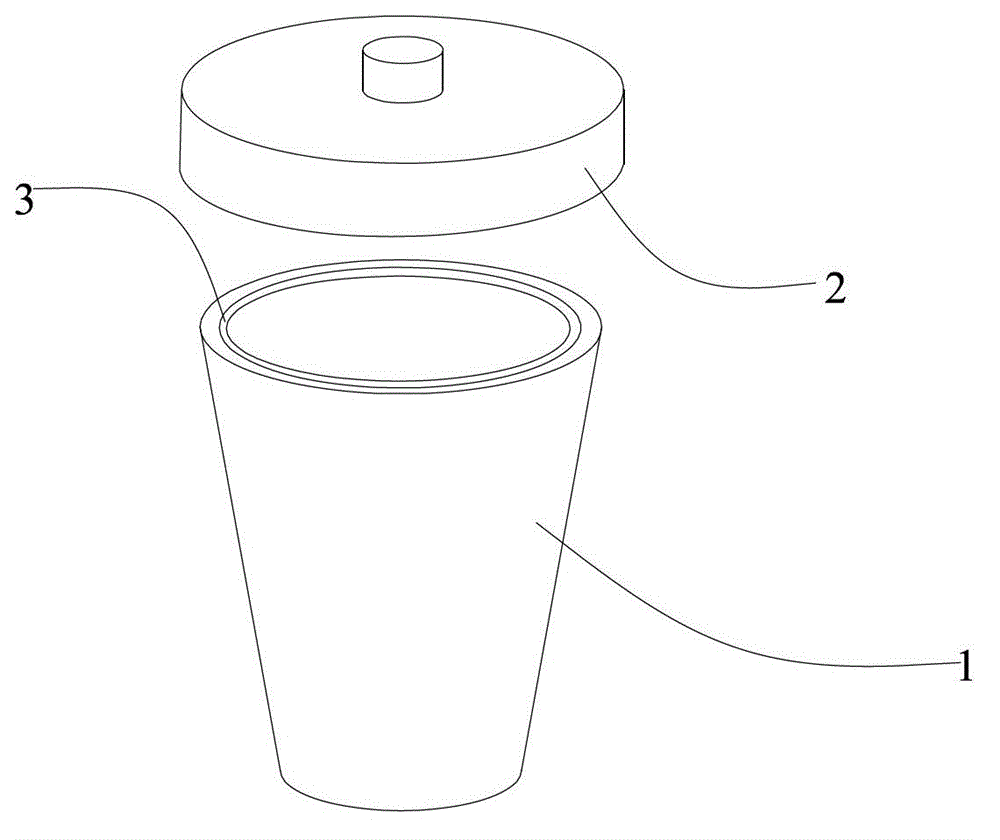

Image

Examples

preparation example Construction

[0022] The preparation method of the composite crucible according to the present invention comprises the steps of: dissolving platinum powder in aqua regia to form a solution, spraying the solution evenly on the inner surface of the ceramic crucible body 1 of the ceramic crucible, and spraying the sprayed ceramic crucible in a heating furnace Body 1 is heated up to 150-250°C, then kept for 2-6 hours, and finally cooled in air. The heating temperature is preferably 170 to 210°C, more preferably 190°C.

[0023] In the preparation method of the composite crucible according to the present invention, the spraying can be performed by a spray gun.

[0024] Next, the method for growing bismuth germanate crystals according to the third aspect of the present invention will be described.

[0025] According to the method for growing bismuth germanate crystals of the present invention, it adopts the composite crucible according to the first aspect of the present invention, and the method ...

Embodiment 1

[0032] According to the ratio of 120g of platinum powder with a purity of 99.99% dissolved in 1.2L of aqua regia to form a solution, the solution is evenly sprayed on the inner surface of the ceramic crucible body 1 (alumina material) of the ceramic crucible by using a spraying tool-spray gun, Heat the sprayed ceramic crucible body 1 in the heating furnace, raise the temperature to 150°C, then keep it warm for 6 hours, and finally cool it by air cooling. Finally, the thickness of the platinum film on the inner surface of the alumina ceramic crucible body 1 is 0.12mm;

[0033] 10kg of 5N bismuth trioxide and 5N germanium oxide powder are batched according to a molar ratio of 2:3, and the batch is melt-cast into 4 bismuth germanate polycrystalline rods;

[0034] The bismuth germanate polycrystalline rods are respectively loaded into the ceramic crucible bodies of 4 aluminum oxide-platinum composite crucibles with a bismuth germanate seed crystal coated with a platinum film thickn...

Embodiment 2

[0039] According to the ratio of 210g of platinum powder with a purity of 99.99% dissolved in 2.52L of aqua regia to form a solution, the solution is evenly sprayed on the inner surface of the ceramic crucible body 1 (BN material) of the ceramic crucible with a spraying tool-spray gun, and heated The sprayed ceramic crucible body 1 is heated in the furnace, the temperature is raised to 200°C, and then kept for 4 hours, and finally air-cooled, and finally the thickness of the platinum film on the inner surface of the ceramic crucible body 1 is 0.20mm;

[0040] The 5N bismuth trioxide and 5N germanium oxide powder of 15kg are batched according to the molar ratio of 2:3, and the batching is melt-casted into 5 bismuth germanate polycrystalline rods;

[0041] The bismuth germanate polycrystalline rods were respectively loaded into the ceramic crucible bodies of five BN-platinum composite crucibles with a BGO seed crystal inner coating thickness of 0.20mm platinum film, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com