Superhydrophobic cloth prepared by layered double hydroxide and its preparation process

A hydroxide and layered double technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of non-repeated use, non-universal applicability, poor stability, etc., and achieve low cost, high-efficiency oil-water separation effect, hydrophobic good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

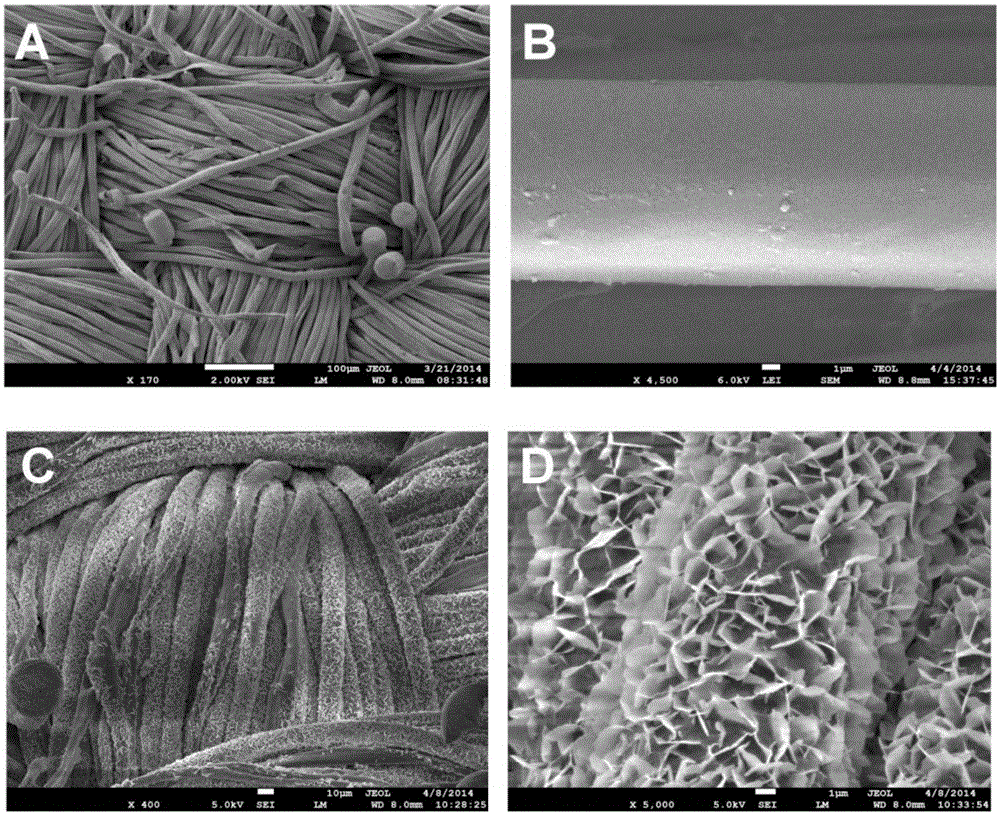

[0029] Example 1: Preparation of superhydrophobic cloth and its scanning electron microscope (SEM) picture

[0030] Preparation of superhydrophobic cloth using layered double hydroxide:

[0031] ① Soak the cloth in 0.1mol / L NaOH solution at 100°C for 60 minutes, then take it out, wash it with water, and dry it;

[0032] ② Prepare 0.2mol / LMg(NO 3 ) 2 and 0.1mol / LAl(NO 3 ) 3 Eutectic aqueous solution 10mL, and quickly added to the vigorously stirred NaOH solution (metal and OH - The ratio is 1:3), the stirring time is 20min, and then the obtained precipitate is centrifuged and washed twice, and then redispersed into water to obtain the seed solution of LDH;

[0033] ③Soak the cloth treated in step ① into the LDH seed solution obtained in step ②, place it in a reaction kettle, and react in an oven at 100°C for 18 hours;

[0034] ④ Cool the cloth treated in step ③, wash and dry, then soak in 0.05mol / L sodium laurate solution, react for 5 hours, then take it out, wash and dry...

Embodiment 2

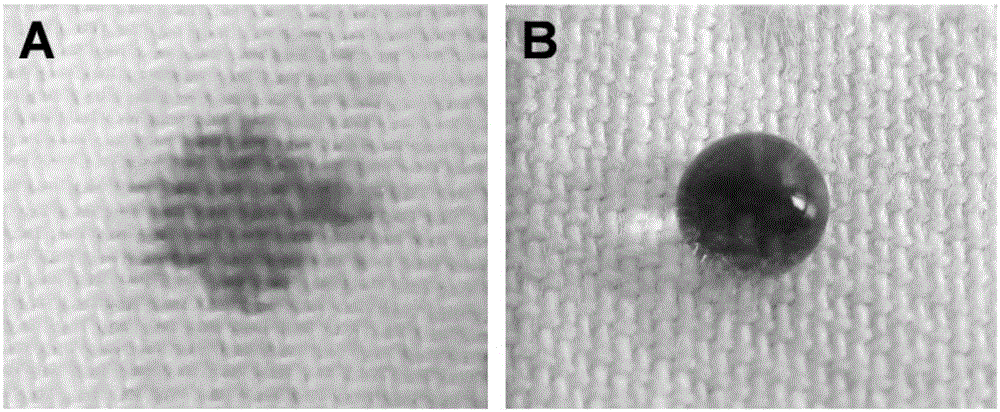

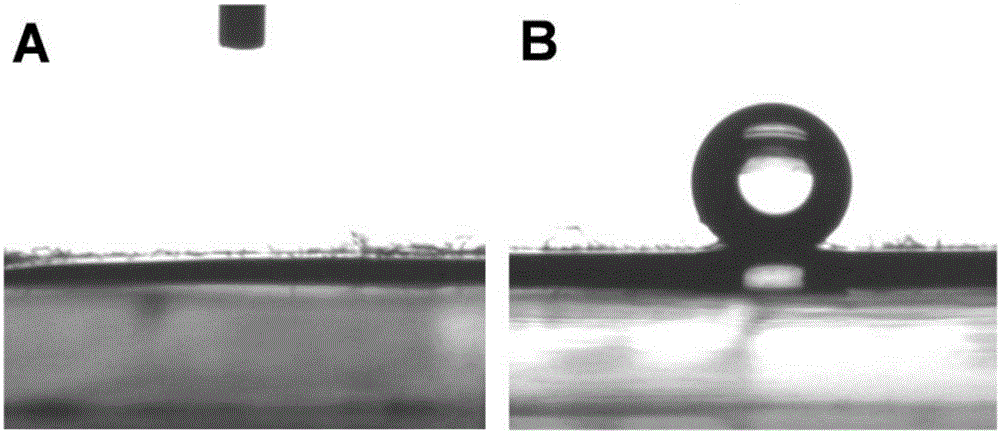

[0037] Example 2: Preparation of superhydrophobic cloth and its use in oil-water separation experiments

[0038] Preparation of superhydrophobic cloth using layered double hydroxide:

[0039] ① Soak the cloth in 0.2mol / L NaOH solution at 90°C for 40 minutes, then take it out, wash it with water, and dry it;

[0040] ② Prepare 0.3mol / LMg(NO 3 ) 2 and 0.1mol / LAl(NO 3 ) 3 Eutectic aqueous solution 10mL, and quickly added to the vigorously stirred NaOH solution (metal and OH - The ratio is 1:2), the stirring time is 30min, and then the obtained precipitate is centrifuged and washed twice, and then redispersed into water to obtain the seed solution of LDH;

[0041] ③Soak the cloth treated in step ① into the LDH seed solution obtained in step ②, place it in a reaction kettle, and react in an oven at 90°C for 24 hours;

[0042] ④ Cool the cloth treated in step ③, wash and dry, then soak in 0.07mol / L sodium laurate solution, react for 4 hours, then take it out, wash and dry to o...

Embodiment 3

[0045] Example 3: Preparation of superhydrophobic cloth and its preparation into an oil-water separation bag and its use in the adsorption test of oil in water

[0046] Preparation of superhydrophobic cloth using layered double hydroxide:

[0047] ① Soak the cloth in 0.3mol / L NaOH solution at 80°C for 50 minutes, then take it out, wash it with water, and dry it;

[0048] ② Prepare 0.1mol / LMg(NO 3 ) 2 and 0.1mol / LAl(NO 3 ) 3 Eutectic aqueous solution 10mL, and quickly added to the vigorously stirred NaOH solution (metal and OH - The ratio is 1:4), the stirring time is 10min, and then the obtained precipitate is centrifuged and washed twice, and then redispersed into water to obtain the seed solution of LDH;

[0049] ③Soak the cloth treated in step ① into the LDH seed solution obtained in step ②, place it in a reaction kettle, and react in an oven at 95°C for 12 hours;

[0050] ④ Cool the cloth treated in step ③, wash and dry, then soak in 0.03mol / L sodium laurate solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com