LED lights for distribution box

A technology for LED lamps and distribution boxes, which is applied in the direction of electric light sources, damage prevention measures for lighting devices, lighting and heating equipment, etc. It can solve the problems of inapplicability and achieve sealing, stable performance, and low permanent deformation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

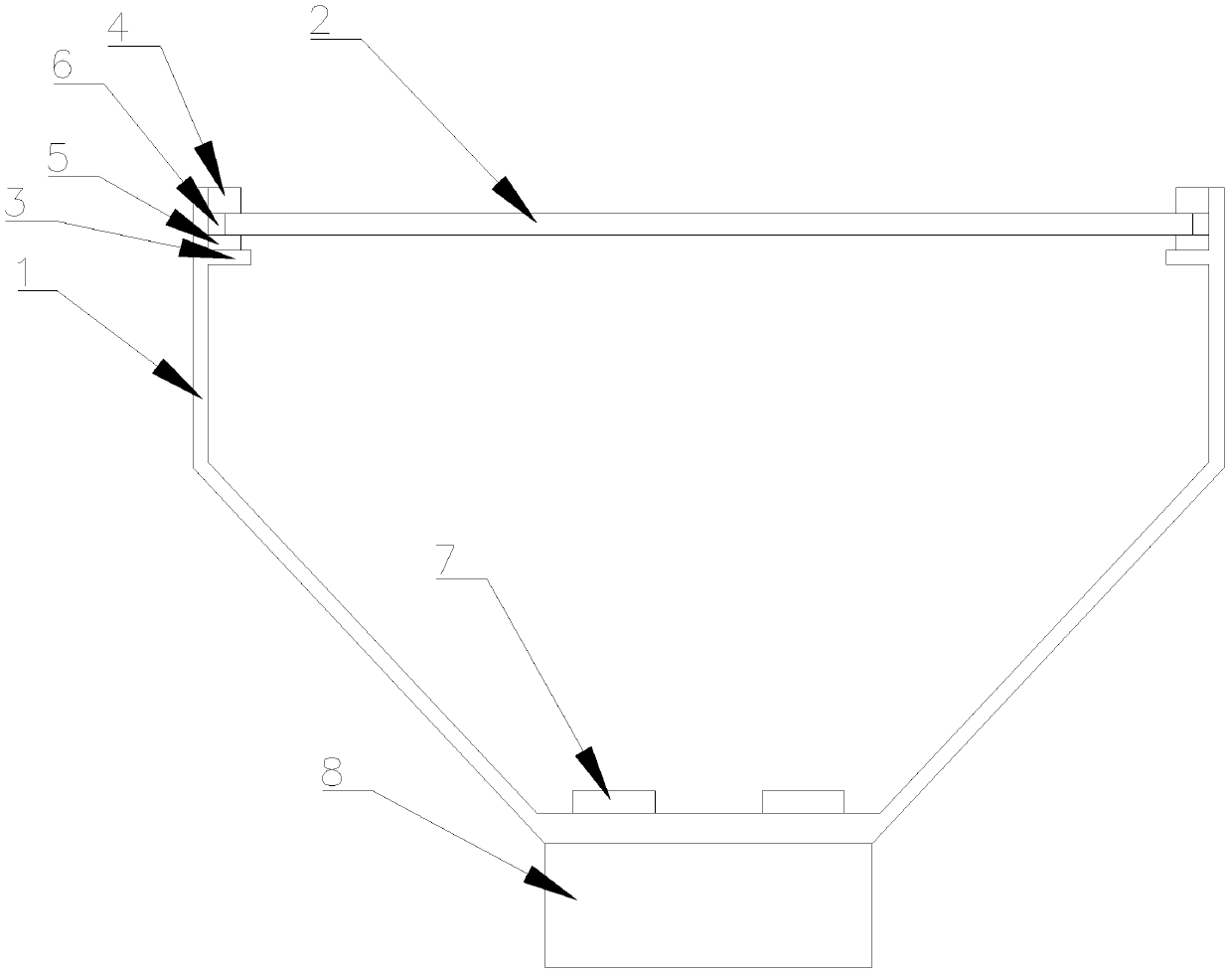

Image

Examples

preparation example Construction

[0029] The preparation method of the annular elastomer material, the steps are:

[0030] 1 Adjust the temperature of the internal mixer to 50-80°C, add chlorinated polyethylene, natural rubber, styrene-butadiene rubber, aromatic oil, zinc oxide, anti-aging agent, and co-crosslinking agent to the internal mixer according to the formula ratio, and mix 1-3min;

[0031] 2 Then add the carbon black in the proportion of the formula, pressurize 8-10Mpa and knead, when the temperature reaches 90-95°C, raise the top bolt, then pressurize 8-10Mpa and continue mixing, when the temperature reaches 100-110°C, deglue— — Filtration — Adding sulfur and accelerators — Inspection — Storage and parking for use.

[0032] A gap 6 is provided between the edge of the light-transmitting plate 2 and the inner surface of the lamp body 1 .

[0033] The thickness of the first annular elastic body 4 is greater than the thickness of the second annular elastic body 5 .

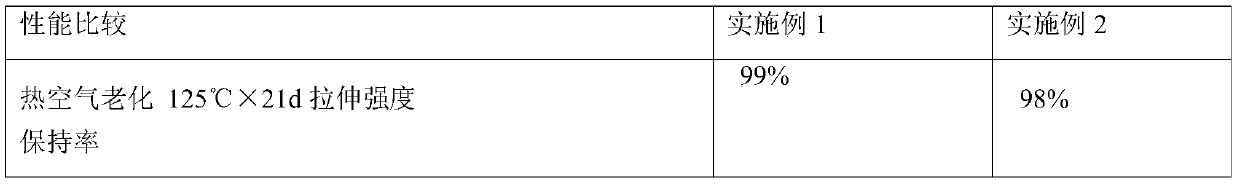

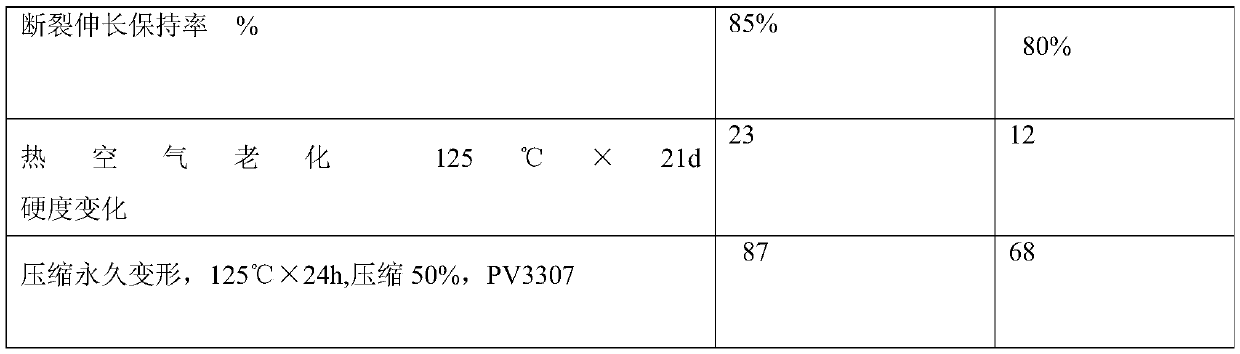

Embodiment 1

[0036] The formula of annular elastomer: 41 parts of chlorinated polyethylene, 15 parts of natural rubber (NR), 6 parts of styrene-butadiene rubber, 3 parts of aromatic oil, 2 parts of anti-aging agent (anti-aging agent SP anti-aging agent 2246 weight ratio 1:1 mixture) , 1 part of sulfur and accelerator (N,N'-diphenylguanidine), 0.3 parts of co-crosslinking agent (triallyl cyanurate), 1.7 parts of zinc oxide, 30 parts of carbon black.

[0037] The preparation method of above-mentioned annular elastomer material, the step is:

[0038] 1 Adjust the temperature of the internal mixer to 75-80°C, add chlorinated polyethylene, natural rubber, styrene-butadiene rubber, aromatic oil, zinc oxide, anti-aging agent, and co-crosslinking agent to the internal mixer according to the formula ratio, and mix 2min;

[0039] 2 Then add the carbon black in the proportion of the formula, pressurize 10MPa and knead, when the temperature reaches 90-95°C, raise the top bolt, then pressurize 10MPa a...

Embodiment 2

[0041]The formula of annular elastomer: 45 parts of chlorinated polyethylene, 11 parts of natural rubber (NR), 7 parts of styrene-butadiene rubber, 4 parts of aromatic oil, 1.5 parts of anti-aging agent (anti-aging agent SP anti-aging agent 2246 weight ratio 1:2 mixture) , sulfur and accelerator (N, N'-diethylthiourea) 1.5 parts, co-crosslinking agent (triallyl isocyanurate) 0.4 parts, zinc oxide 1.6 parts, carbon black 28 parts.

[0042] The preparation method of above-mentioned annular elastomer material, the step is:

[0043] 1 Adjust the temperature of the internal mixer to 55-60°C, add chlorinated polyethylene, natural rubber, styrene-butadiene rubber, aromatic oil, zinc oxide, anti-aging agent, and co-crosslinking agent to the internal mixer according to the formula ratio, and mix 3min;

[0044] 2 Then add the carbon black in the proportion of the formula, pressurize 9MPa and knead, raise the top bolt when the temperature reaches 90-95°C, then pressurize 9MPa and contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com