Circular oil-submerged pump cable

A submersible pump, circular technology, applied in the field of circular submersible pump cables, can solve the problems of short service life, hysteresis loss, poor compactness, etc., and achieve the effects of small mutual interference, improved compactness, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

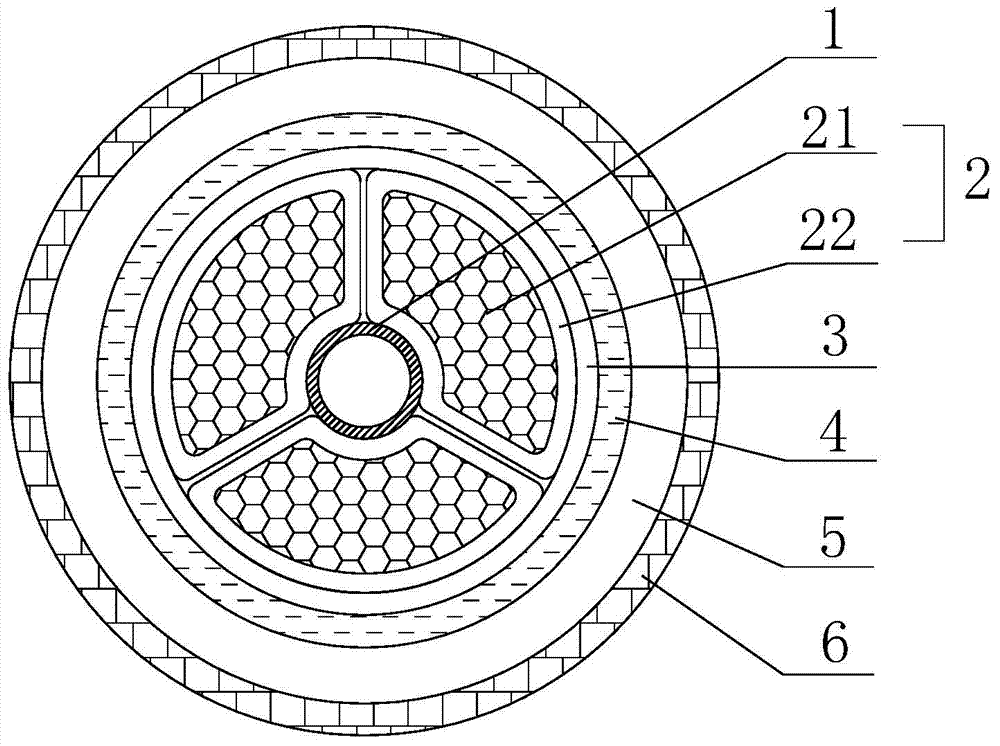

[0017] like figure 1 as shown, figure 1 It is a structural schematic diagram of a circular submersible pump cable proposed by the present invention.

[0018] The cable proposed by the present invention may include two or more wires, and the cable in this embodiment exemplarily includes three wires.

[0019] refer to figure 1 , a circular submersible pump cable proposed by the present invention includes a cable core composed of an aluminum-plastic tube 1 and three wires 2 .

[0020] The aluminum-plastic pipe 1 has a circular cross section, with an aluminum foil layer in the middle and plastic layers on both sides. The wire 2 includes a conductor 21 located in the middle. The conductor 21 is twisted from a plurality of tinned oxygen-free copper wires. The conductor 21 is covered with an insulating layer 22 to ensure mutual insulation between the wires 2 and realize the power transmission function of the cable.

[0021] In the process of arranging the aluminum-plastic pipe an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com