Cathode water management structure of passive alcohol type fuel battery

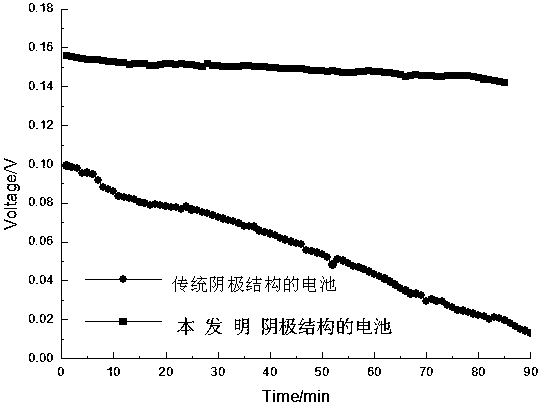

A fuel cell, passive technology, used in fuel cells, fuel cell additives, battery electrodes, etc., can solve the problem of self-breathing channel blockage in the cathode flow field, and achieve the prevention of flooding, good insulation performance, and battery short-circuit prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

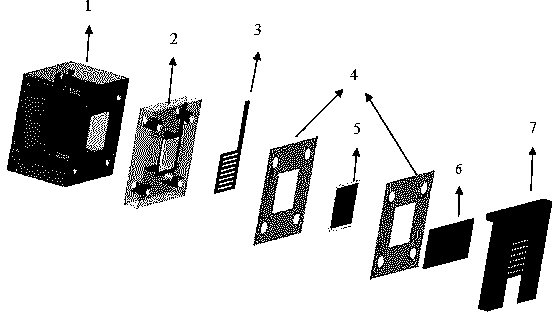

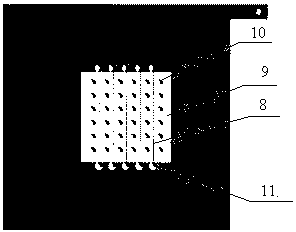

[0024] Specific implementation mode 1: In this implementation mode, an aluminum alloy is used to make the cathode flow field plate 7, and its structure is as follows Figure 2-3 As shown, self-breathing through holes 10 are arranged on the cathode flow field plate 7, an upper channel 8 is arranged on the back side of the cathode flow field plate 7, and between two adjacent self-breathing through holes 10, each upper channel 8 Below, the front of the cathode flow field plate 7 is provided with a lower channel 12, and the two adjacent upper channels 8 and the lower channels 12 are connected through round holes 11, so that liquid water can flow along the upper channel 8 and the lower channel 12. The lower channel 12 flows from the inside to the outside, and is prepared by micro-arc oxidation technology on the upper channel 8 for collecting liquid water, the lower channel 12, and the surface where the cathode flow field plate 7 and the cathode current collector plate 6 are in conta...

specific Embodiment approach 2

[0026] Specific embodiment two: The difference between this embodiment and specific embodiment one is: the electrolytic solution adopted during the micro-arc oxidation treatment of the cathode flow field plate 7 is 10 g / mL of sodium aluminate and 1 g / mL of sodium hypophosphite mixture.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiments 1 and 2 is that the power source used in the micro-arc oxidation treatment of the cathode flow field plate 7 is a DC power supply, and the processing voltage is 300-600V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com