Crab shell enzymolysis device

A crab shell and enzymatic hydrolysis technology, which is applied in the field of biological enzymatic hydrolysis equipment, can solve the problems of large amount of waste water, waste of useful resources, environmental pollution, etc., and achieve the effect of uniform mixing, uniform concentration, and guaranteed enzymatic hydrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

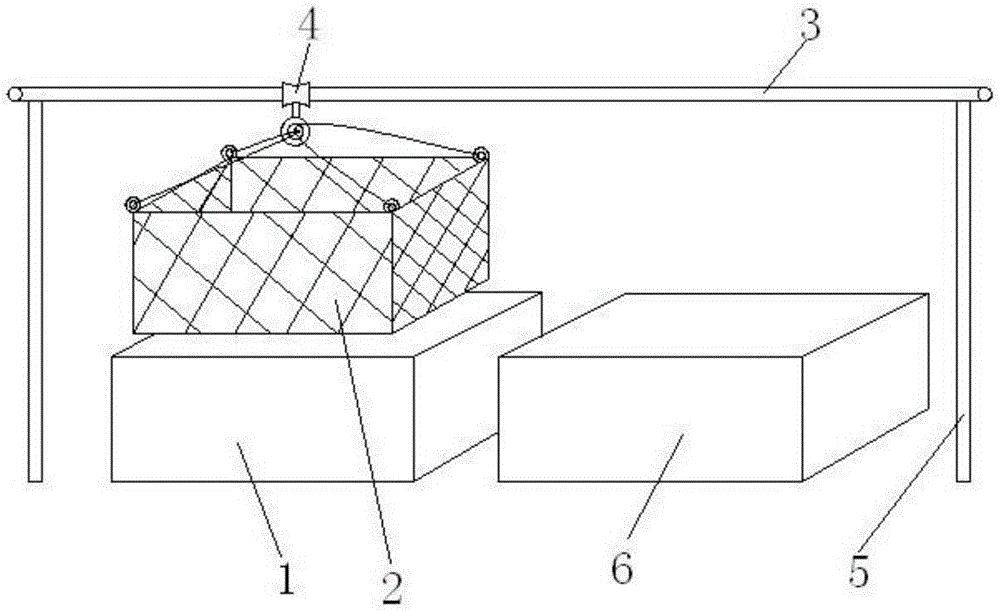

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] like figure 1 Shown, a kind of crab shell enzymatic hydrolysis device is characterized in that: comprise: Enzymolysis tank 1, crab cage 2, support bar 3, slide tube 4, lifting bar 5 and cleaning pool 6; Described slide tube 4 is arranged on the and slide on the support rod 3, the two ends of the support rod 3 are provided with the lifting rod 5, the crab cage 2 is hoisted under the slide tube 4, and the crab cage 2 is lifted under the crab cage 2. The enzymolysis pool 1 and the cleaning pool 6 arranged in parallel are provided. The minimum height of the lifting rod is the height of the crab cage 2, and the maximum height of the lifting rod is greater than the sum of the heights of the enzymolysis pool 1 and the crab cage 2. The height of the crab cage 2 is greater than the height of the enzymolysis pond 1, the length, width and height of the enzymolysis pond 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com