Automatic control turntable pneumatic multi-sprayer biological 3D (three dimensional) printing forming system and method

A 3D printing, multi-nozzle technology, applied in the direction of bone implants, etc., to achieve the effect of easy control, increased stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

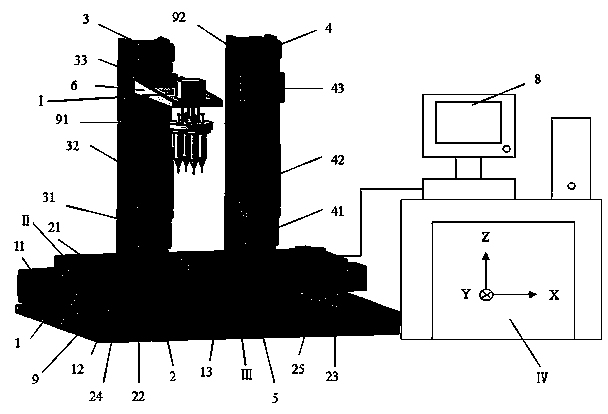

[0055] see Figure 1~Figure 3 , the automatically controlled turntable pneumatic multi-nozzle biological 3D printing forming system includes an injection device, a three-dimensional motion mechanism, a forming table and a control and data processing system, and is characterized in that: the said injection device adopts a turntable multi-nozzle injection device, It is installed on the Z1-axis motion mechanism in the three-dimensional motion mechanism and slides up and down with the Z1-axis motion slider; the forming table is installed on the X-axis motion slider in the three-dimensional motion mechanism; the control and data processing system is a joint control Rotary disc type multi-nozzle spraying device and motor of three-dimensional motion mechanism.

[0056]

Embodiment 2

[0058] This example is basically the same as Example 1, the special features are as follows:

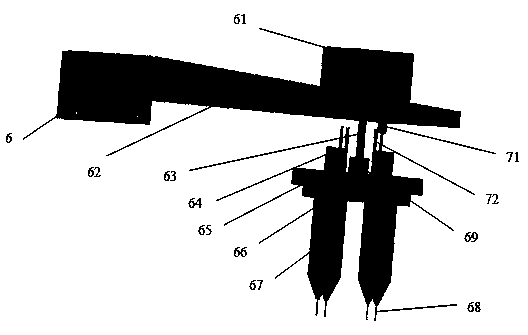

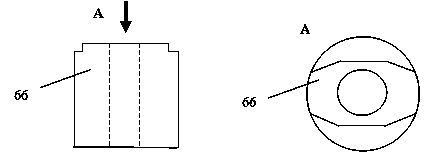

[0059] The turntable multi-nozzle injection device includes a control turntable motor, a crossbeam, a motor shaft, a connecting pipe, a turntable, a nut, a syringe piston cylinder, a syringe needle, a shaft sleeve, a groove-type photoelectric switch, and a groove-type photoelectric switch shield; The beam is fixedly installed on the Z1-axis motion slider; the control turntable motor is fixedly installed on the beam through screws, and the motor shaft faces downward; the shaft sleeve is an externally threaded sleeve, and the motor shaft is threadedly connected to one end of the shaft sleeve; There is a through hole in the middle of the turntable, the inner ring is an internal thread, and the turntable is connected to the other end of the bushing, which is an internal and external thread connection; the control turntable motor drives the motor shaft to rotate, and at the same time drive...

Embodiment 3

[0065] see Figure 4 , using the above-mentioned system to perform bio-3D printing forming method to realize the preparation of heterogeneous multi-material gradient regenerative bone scaffold, characterized in that it includes the following steps:

[0066] a. Before preparing the shaped bracket, the three-dimensional model is obtained through CT scanning reconstruction, and the model is layered with data processing software to obtain the formed coordinate G code, and the file is input into the computer control software;

[0067] b. Load the mixed 3D printing material solution into the syringe piston cylinder of the piston syringe respectively, eliminate the air bubbles in the syringe piston cylinder, and then install the syringe piston cylinder on the turntable;

[0068] c. Connect the turntable multi-nozzle injection device with the three-dimensional motion mechanism, install it on the Z1-axis motion slider, use the control and data processing system to drive the three-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com