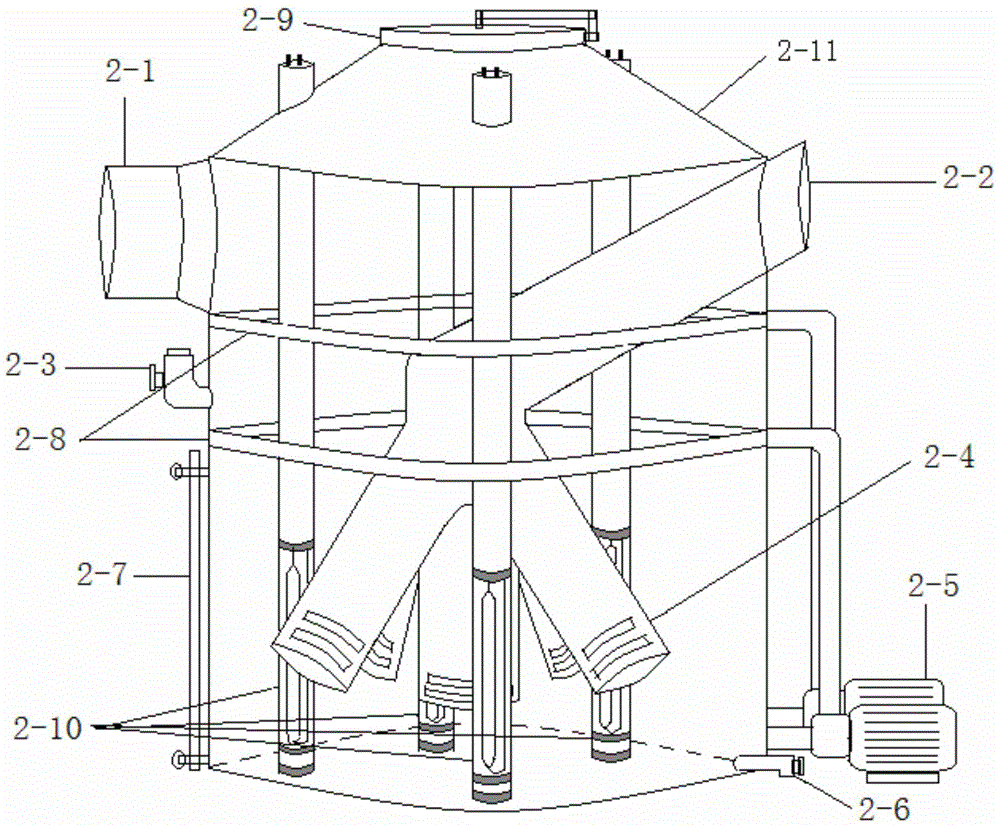

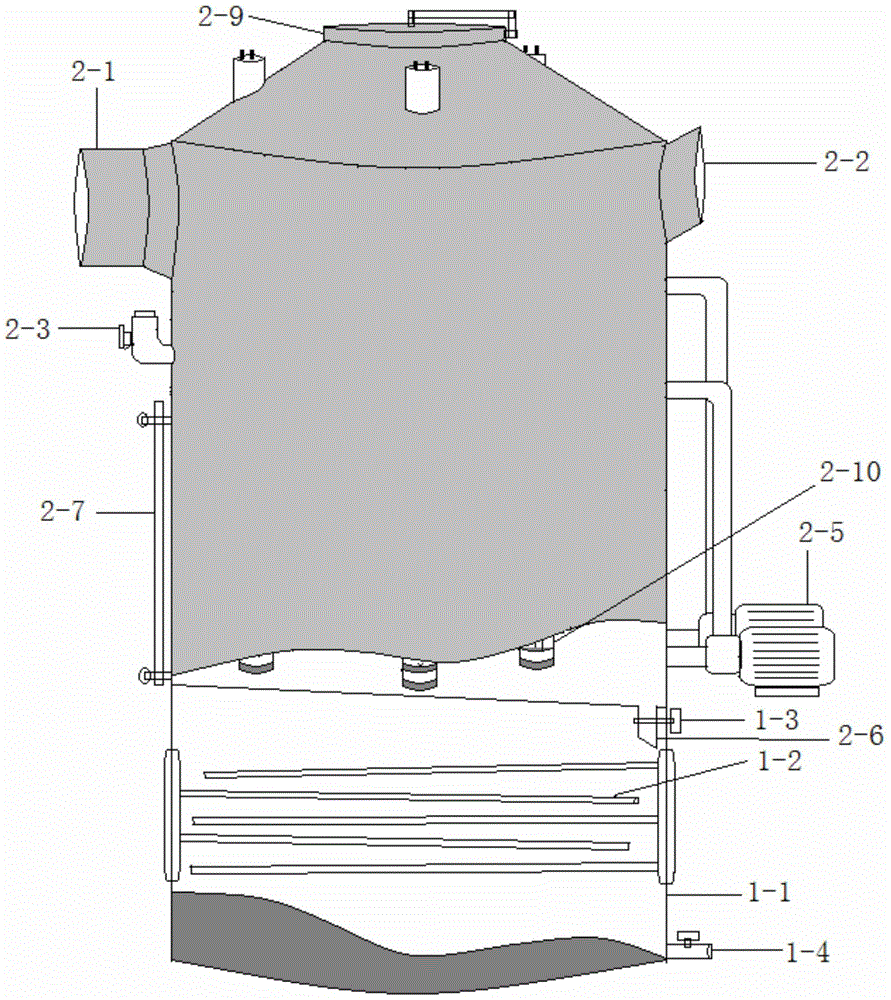

A method and device for purifying flue gas by using light-assisted Fenton reaction

A Fenton reaction and flue gas technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of high investment, high steel consumption, huge maintenance costs, etc., and achieve the effect of less consumption and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1: a kind of method utilizing light to assist Fenton reaction to purify flue gas is characterized in that comprising the following steps:

[0081] (1) Adding a solution containing Fenton’s reagent and adjusting the pH value to less than or equal to 3 by using an α-hydroxy acid in the reaction vessel, the Fenton’s reagent comprising a metal system capable of photo-assisted Fenton reaction and hydrogen peroxide;

[0082] The mass percentage of described solution configuration hydrogen peroxide and water is 5%;

[0083] The molar ratio of hydrogen peroxide to metal system is about 30:1;

[0084] (2) According to the light absorption peak of the metal system, the lighting system is set;

[0085] (3) The flue gas is passed into the reaction vessel, so that the pollutants in the flue gas fully contact and react with the Fenton reagent;

[0086] (4) The solution after the reaction is exported, and the concentration of the Fenton's reagent in the derivation solutio...

Embodiment 2

[0118] A method for purifying flue gas by light-assisted Fenton reaction, characterized in that it comprises the following steps:

[0119] (1) Adding a solution containing Fenton’s reagent and adjusting the pH value to be less than or equal to 3 by using an α-hydroxy acid in the reaction vessel, the Fenton’s reagent comprising a metal system capable of photo-assisted Fenton reaction and hydrogen peroxide;

[0120] The mass percentage of described solution configuration hydrogen peroxide and water is 4%;

[0121] The molar ratio of hydrogen peroxide to metal system is 10:1;

[0122] (2) According to the light absorption peak of the metal system, the lighting system is set;

[0123] (3) The flue gas is passed into the reaction vessel, so that the pollutants in the flue gas fully contact and react with the Fenton reagent;

[0124] (4) The solution after the reaction is exported, and the concentration of Fenton's reagent in the derivation solution is regularly monitored, and acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com