Method and device for purifying flue gas containing dust

A flue gas and dust technology, which is applied in the field of purifying flue gas containing dust, can solve the problems of huge equipment, sick operation, and only shutdown for maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

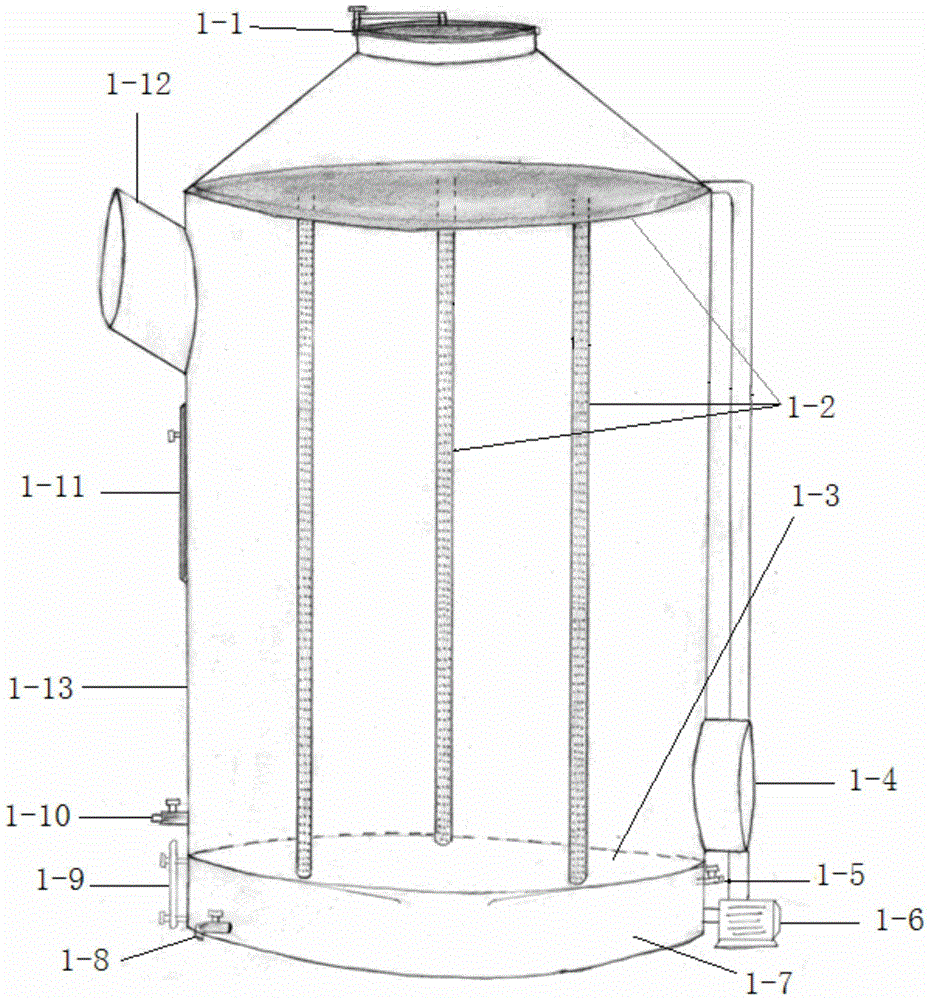

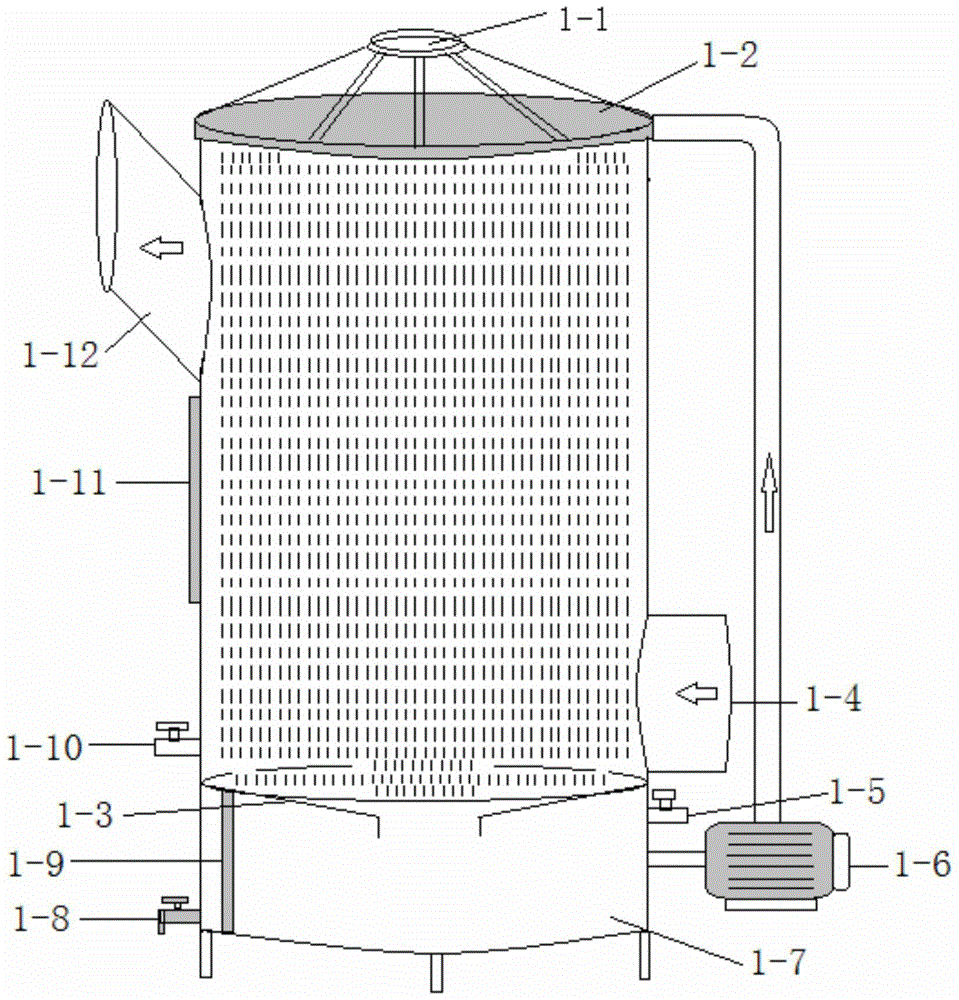

[0070] Embodiment 1: a kind of method for processing the flue gas that contains dust, it is characterized in that comprising the following steps:

[0071] (1) add water in the pretreatment container;

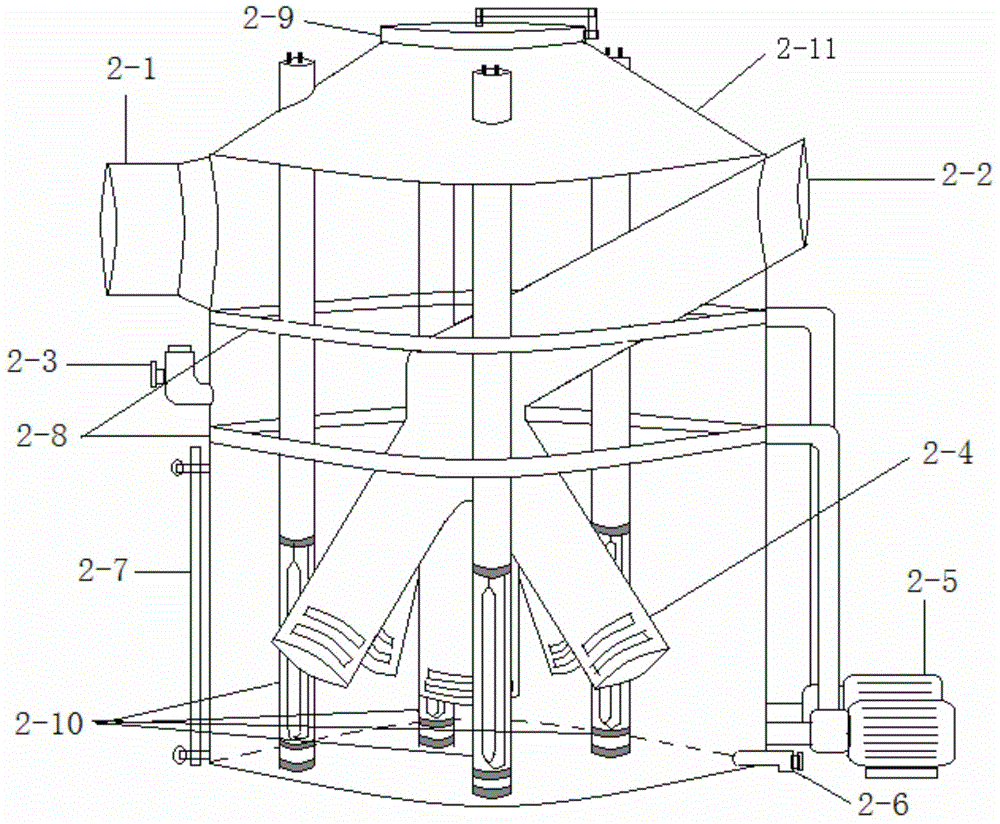

[0072] (2) Adding a solution containing Fenton's reagent and adjusting the pH value to less than or equal to 3 by using an α-hydroxy acid in the reaction vessel, the Fenton's reagent comprising a metal system capable of photo-assisted Fenton reaction and hydrogen peroxide;

[0073] The mass percentage of described solution configuration hydrogen peroxide and water is 5%;

[0074] The molar ratio of hydrogen peroxide to metal system is about 30:1;

[0075] (3) According to the light absorption peak of the metal system, an illumination system is set in the reaction vessel;

[0076] (4) Pass the exhaust gas into the pretreatment container, fully contact with the liquid, so that the solid particles with a diameter greater than 10 microns remain in the liquid;

[0077] (5) Leading...

Embodiment 2

[0122] A method for treating flue gas containing dust, characterized in that it comprises the following steps:

[0123] (1) add water in the pretreatment container;

[0124] (2) Adding a solution containing Fenton's reagent and adjusting the pH value to less than or equal to 3 by using an α-hydroxy acid in the reaction vessel, the Fenton's reagent comprising a metal system capable of photo-assisted Fenton reaction and hydrogen peroxide;

[0125] The mass percentage of described solution configuration hydrogen peroxide and water is 4%;

[0126] The molar ratio of hydrogen peroxide to metal system is 10:1;

[0127] (3) According to the light absorption peak of the metal system, an illumination system is set in the reaction vessel;

[0128] (4) Pass the exhaust gas into the pretreatment container, fully contact with the liquid, so that the solid particles with a diameter greater than 10 microns remain in the liquid;

[0129] (5) Leading the liquid containing solid particles wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com