System for treating boiler flue gas and working method thereof

A technology for boiler flue gas and flue gas, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as pollution and violation of pollution control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

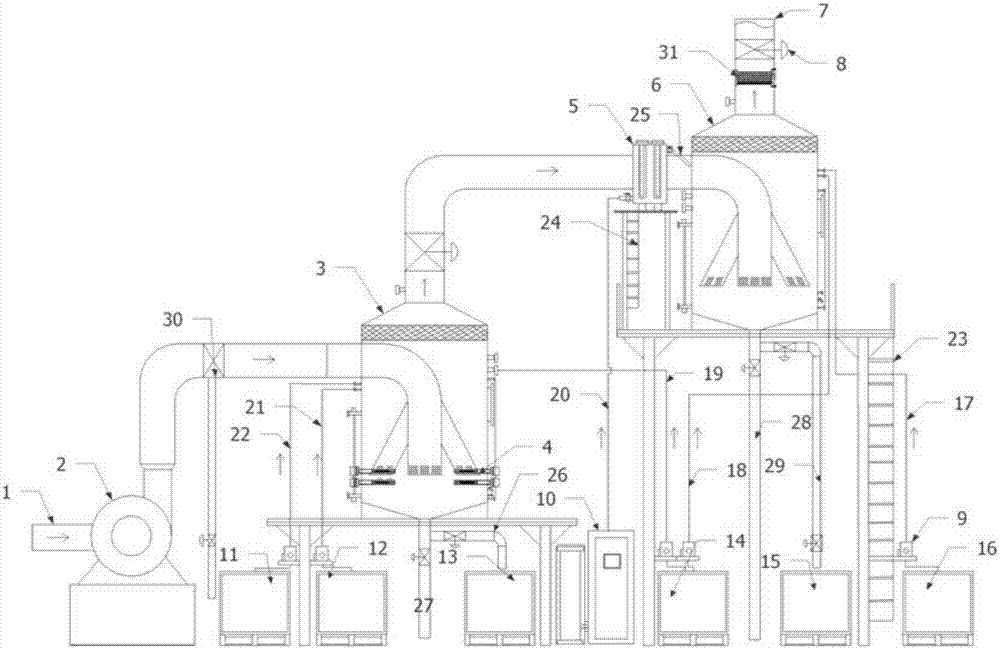

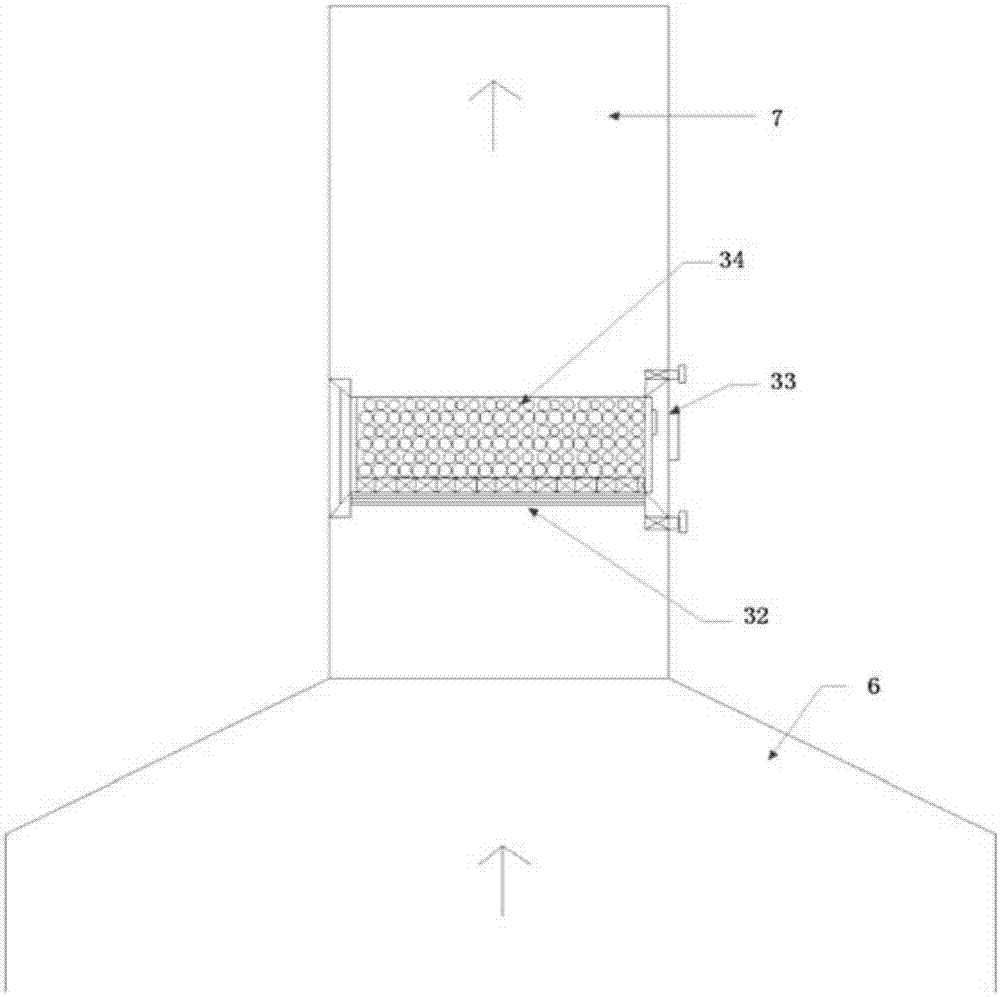

[0120] Embodiment: a kind of system of controlling boiler flue gas (see Figure 1 to Figure 2 ), which includes induced draft fan, bag dust removal device, booster fan, desulfurization tank 3, photolysis catalytic system 5, denitrification tank 6, ozone treatment escape system 31, chemical reagent A dosing tank 14, chemical reagent B dosing tank 11 , chemical reagent C dosing tank 12, chemical reagent D dosing tank 16, metering pump 9, desulfurization tank collection tank 13, denitrification tank collection tank 15;

[0121] The boiler flue gas enters the bag filter through the induced draft fan, and the output end of the bag filter is connected to the input end of the booster fan 2 through the flue gas inlet 1, and the output end of the booster fan 2 is connected to the input end of the desulfurization tank 3, and the flue gas The booster fan 2 enters the desulfurization tank 3, and the flue gas enters the tank and the absorption liquid containing Fenton's reagent in the tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com