Safety device for oxalate production by CO gas phase oxidative coupling and temperature jump control method

A technology of oxidative coupling and safety device, which is applied in the direction of carbon monoxide or formate reaction preparation, nitrate ester preparation, temperature control by electric method, etc. It can solve the problem of high human resource consumption, difficulty in automatic and rapid processing of flying temperature, and difficulty in recovery Production and other issues to ensure the smooth progress of production, avoid danger, and save human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

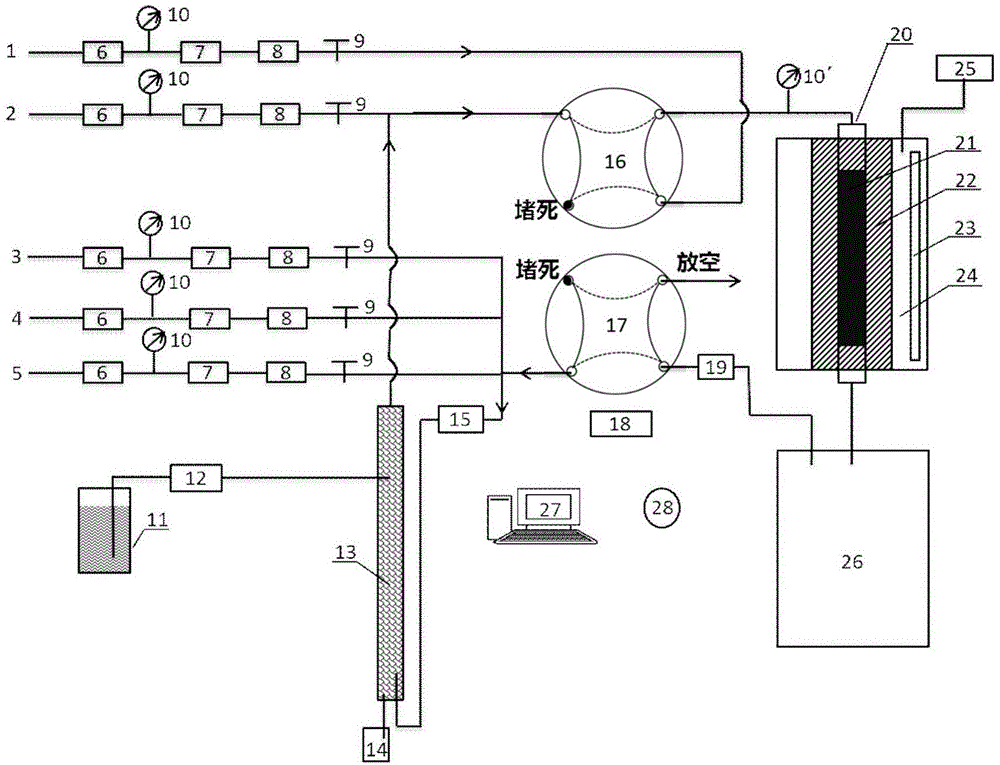

[0036]The safety device for producing dimethyl oxalate through gas-phase oxidation coupling of CO disclosed by the present invention comprises a first nitrogen gas control pipeline (1), a carbon monoxide gas control pipeline (2), a second nitrogen gas control pipeline (3), and a nitrogen monoxide gas control pipeline. Control pipeline (4), oxygen gas control pipeline (5), total pressure gauge (10′), methanol storage tank (11), liquid pump (12), esterification tower (13), waste water storage tank (14), gas Mixing box (15), first pneumatic four-way valve (16), second pneumatic four-way valve (17), valve controller (18), circulation pump (19), reactor (20), heating furnace (22) , fan (23), control box (24), alarm (25), dimethyl oxalate collection tank (26) and computer (27);

[0037] Among them: the above-mentioned gas control pipelines (1, 2, 3, 4, 5) all include gas pipelines connected in sequence, a pressure stabilizing valve (6), a pressure gauge (10), a stabilizing flow valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com