A Mechanical Valve for Reducing Intake Backpressure of Air-breathing Pulse Detonation Engine

A technology of pulse detonation and air intake, which is applied in the field of mechanical valves to achieve the effect of reducing the flow area, shortening the length, and improving the stability of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

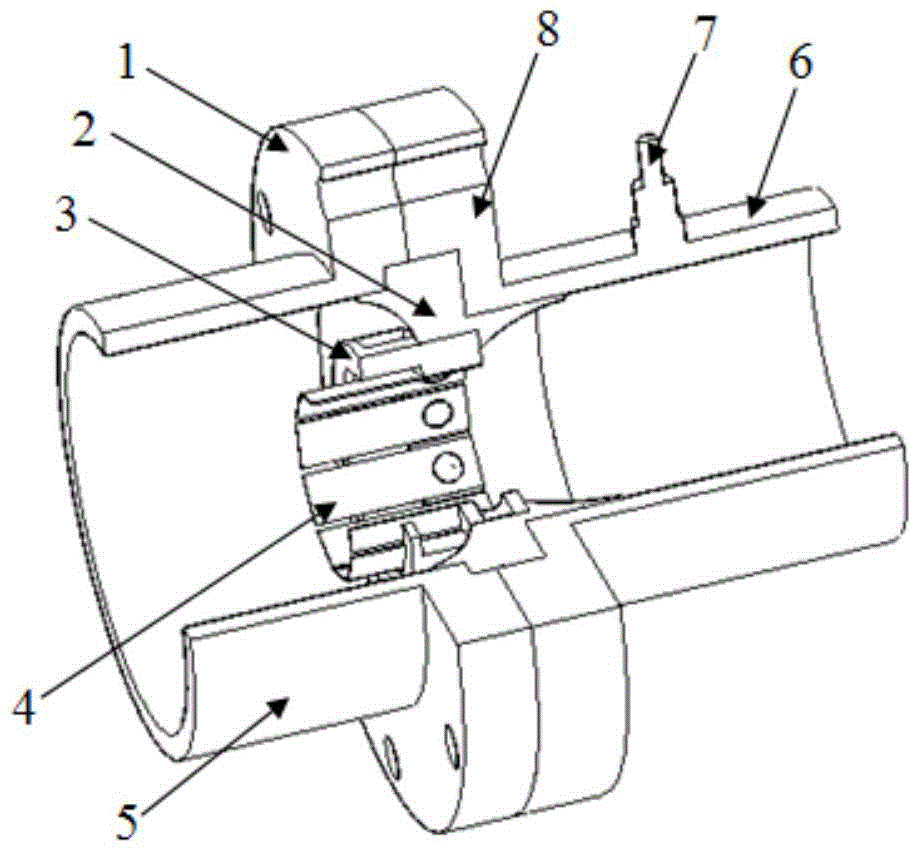

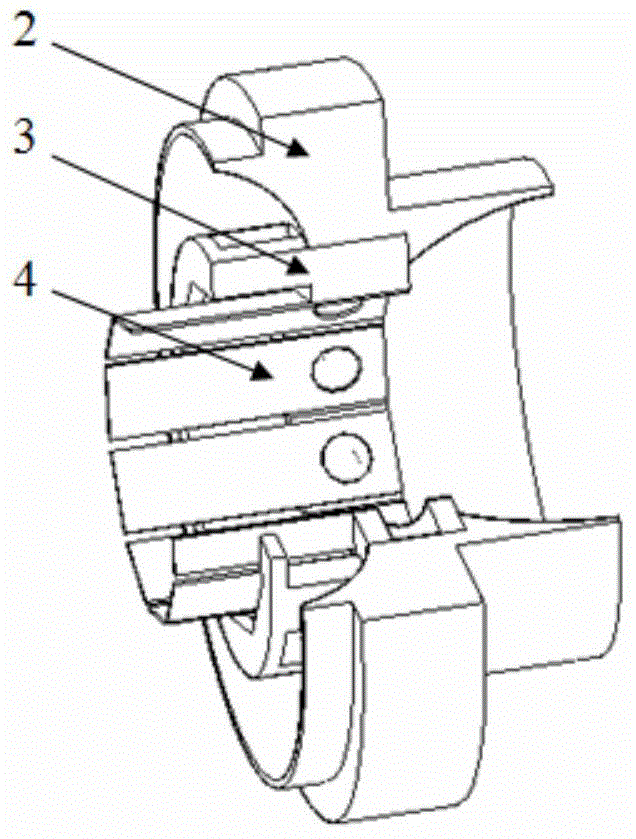

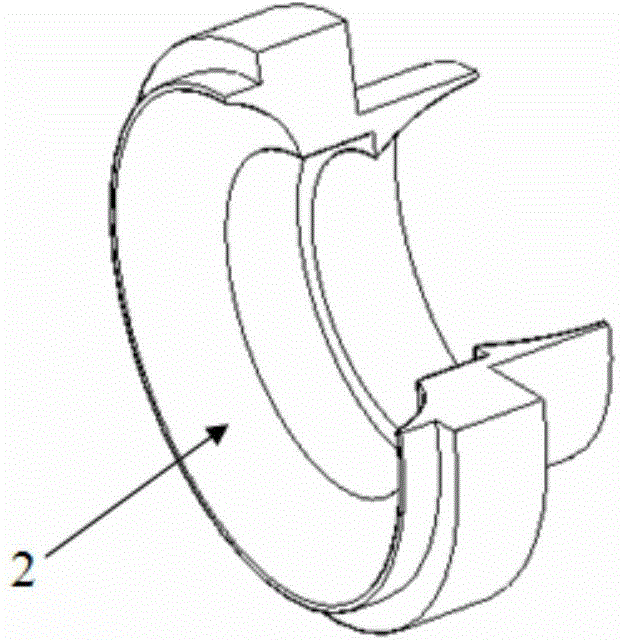

[0023] This embodiment is a mechanical valve for reducing the back pressure of the air intake of an air-breathing pulse detonation engine.

[0024] refer to Figure 1 to Figure 6 , the present embodiment reduces the mechanical valve of air-breathing pulse detonation engine air inlet back pressure, connects flange 1, Venturi 2, air intake cover 3, elastic reed 4, air inlet by air inlet shell Shell 5, detonation chamber shell 6, spark plug 7, detonation chamber shell connecting flange 8, air intake hole 9, boss 10, threaded hole 11, through hole 12, air intake duct 13, air intake cone 14 , intake cone cylinder 15, fuel nozzle 16, detonation chamber 17, and detonation intensifying device 18, the connecting flange 1 of the inlet casing and the connecting flange 8 of the detonation chamber casing are relatively buckled to form an axially penetrating In the annular groove, the Venturi 2 is fixed in the groove, and the connecting flange 1 of the inlet casing and the connecting flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com