Thermoplastic resin composition, and molded product using same

A thermoplastic resin and composition technology, applied in the field of thermoplastic resin composition and molded products using the same, can solve the problems of environmental pollution, no scratch resistance, limited coloring performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6 and comparative example 1 to 7

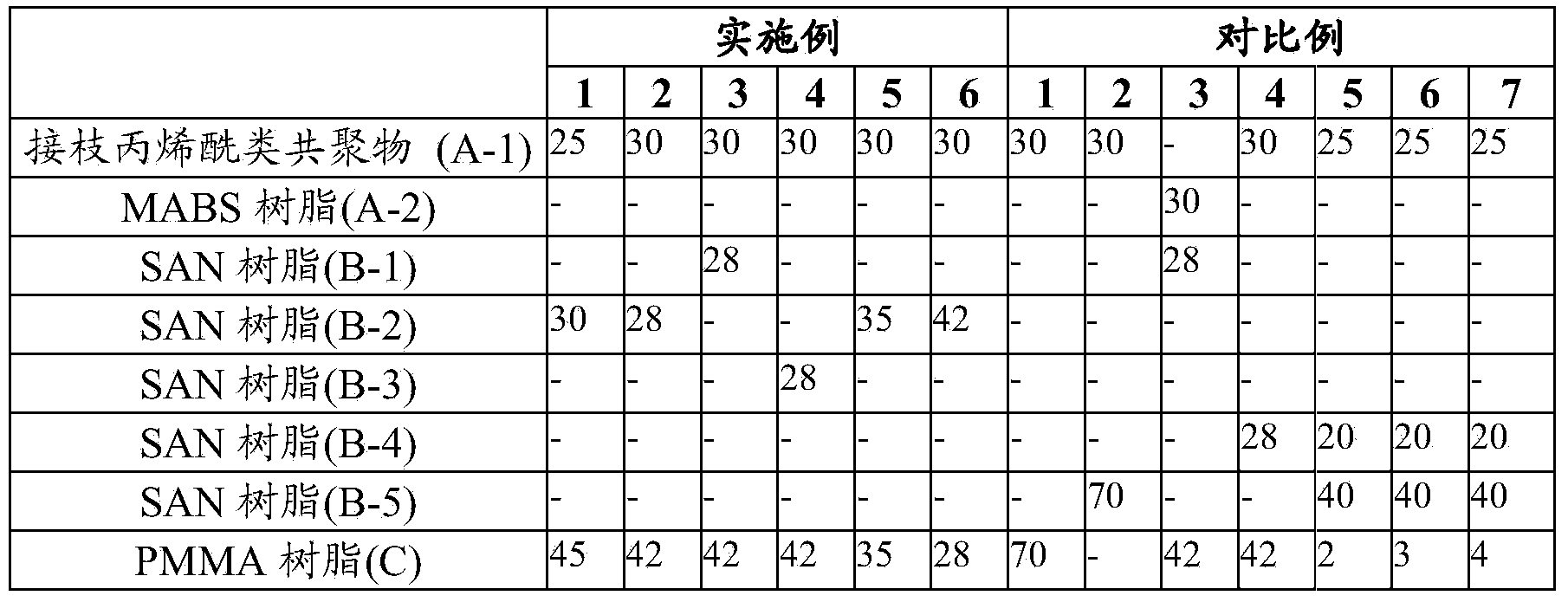

[0094] Each thermoplastic resin composition according to Examples 1 to 6 and Comparative Examples 1 to 7 was prepared to have the composition in Table 1 below by using the above-mentioned components.

[0095] Other additives were added to each thermoplastic resin composition in Table 1 below, and the mixture was separately extruded / processed to obtain a pellet type thermoplastic resin. Extrusion was performed by using a twin-screw extruder having L / D=29 and a diameter of 45 mm and setting a Barell temperature of 230°C. The prepared pellets were dried at 80°C for 2 hours and then prepared for the measurement of scratch resistance, optical properties and Weather resistance 9 cm x 5 cm x 0.2 cm size samples for measuring properties.

experiment example 1

[0096] Experimental Example 1: Mechanical Properties

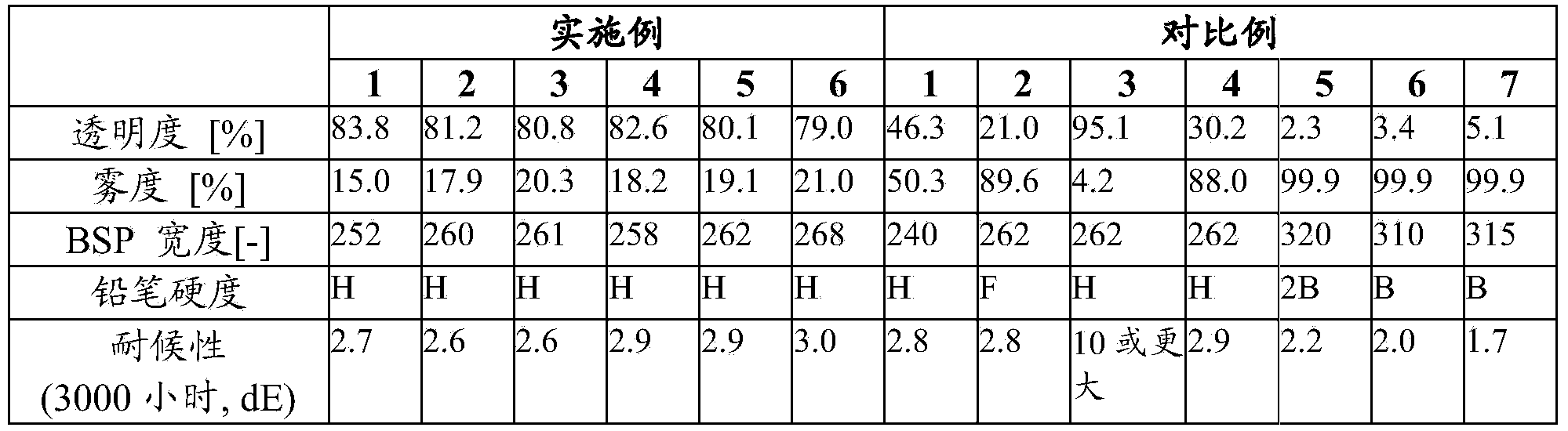

[0097] The properties of the prepared samples were measured by the following methods, and the results are provided in Table 2 below.

[0098] (1) Transparency and haze: measured according to ASTM D1003 standard

[0099] (2) BSP (Ball Scratch Profile) Width: under loads of 300 g, 500 g and 1000 g, respectively, using a tungsten carbide tipped pen with a domed tip of 0.7 mm diameter and at a speed of 75 mm / min on the sample Scratch, then use surface profiling to check roughness and measure scratch width according to the first woolen method.

[0100] (3) Pencil hardness: Measure the hardness when a load of 500 g is applied to the pencil and pushed 5 times at a speed of 10 mm / s without scratches (pencil and pencil hardness according to JIS K5401).

[0101] (4) Weather resistance: measured according to SAE J1960 (3,000 hours, ΔE)

[0102] (Table 1)

[0103]

[0104] (Table 2)

[0105]

[0106] The samples according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com