A novel chromatographic media based on allylamine and its derivative for protein purification

A chromatographic medium, technology of allylamine, applied in chromatographic cation exchangers, chromatographic anion exchangers, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Preparation of main ligand and ion exchange chromatographic medium using polyallylamine

[0037] 100 ml of 15 (w / w) % polyallylamine (molecular weight 15,000) aqueous solution and 300 ml of deionized water were charged into a 1 liter 3-necked flask equipped with a stirrer, condenser, nitrogen inlet and temperature controller. 25 grams of polymethacrylate polymer containing reactive epoxy groups (median particle size 35 microns) was slowly added to the reactor while stirring. The flask was then heated to 80°C and reacted for 16 hours. The reaction product was washed once with deionized water and then four times with 1-methoxy-2-propanol. Elemental analysis: C, 58.3%, H, 7.3%, N, 1.1%.

[0038] The polymer obtained by the above reaction was then transferred to a dry 1 liter 3-necked flask equipped with a stirrer, condenser, nitrogen inlet and temperature controller. 400 ml of 1-methoxy-2-propanol and 14.5 g of maleic anhydride were added to the flask under...

Embodiment 3

[0042] Example 3: Preparation of Host Media by Intermolecular Polymerization

[0043] 10 g of allylamine was dissolved in 400 ml of 1-methoxy-2-propanol and the solution was transferred to a 1 liter 3-necked flask equipped with a stirrer, condenser, nitrogen inlet and temperature controller. 25 g of polymethacrylate polymer containing reactive epoxy groups (median particle size 35 microns) was slowly added to the reactor. The flask was then heated to 80°C and reacted for 16 hours. The reaction product was washed with deionized water followed by alcohol four times.

[0044] The polymer grafted with allylamine obtained by the above reaction was then transferred to a dry 1 liter 3-neck flask equipped with a stirrer, condenser, nitrogen inlet and temperature controller. After nitrogen purging, 400 ml of ethanol was added to the flask. The flask was heated to 80° C. and 0.6 g of AIBN was added, then 15 g of allylamine was added through a syringe pump at a flow rate of 0.2 ml / m...

Embodiment 4

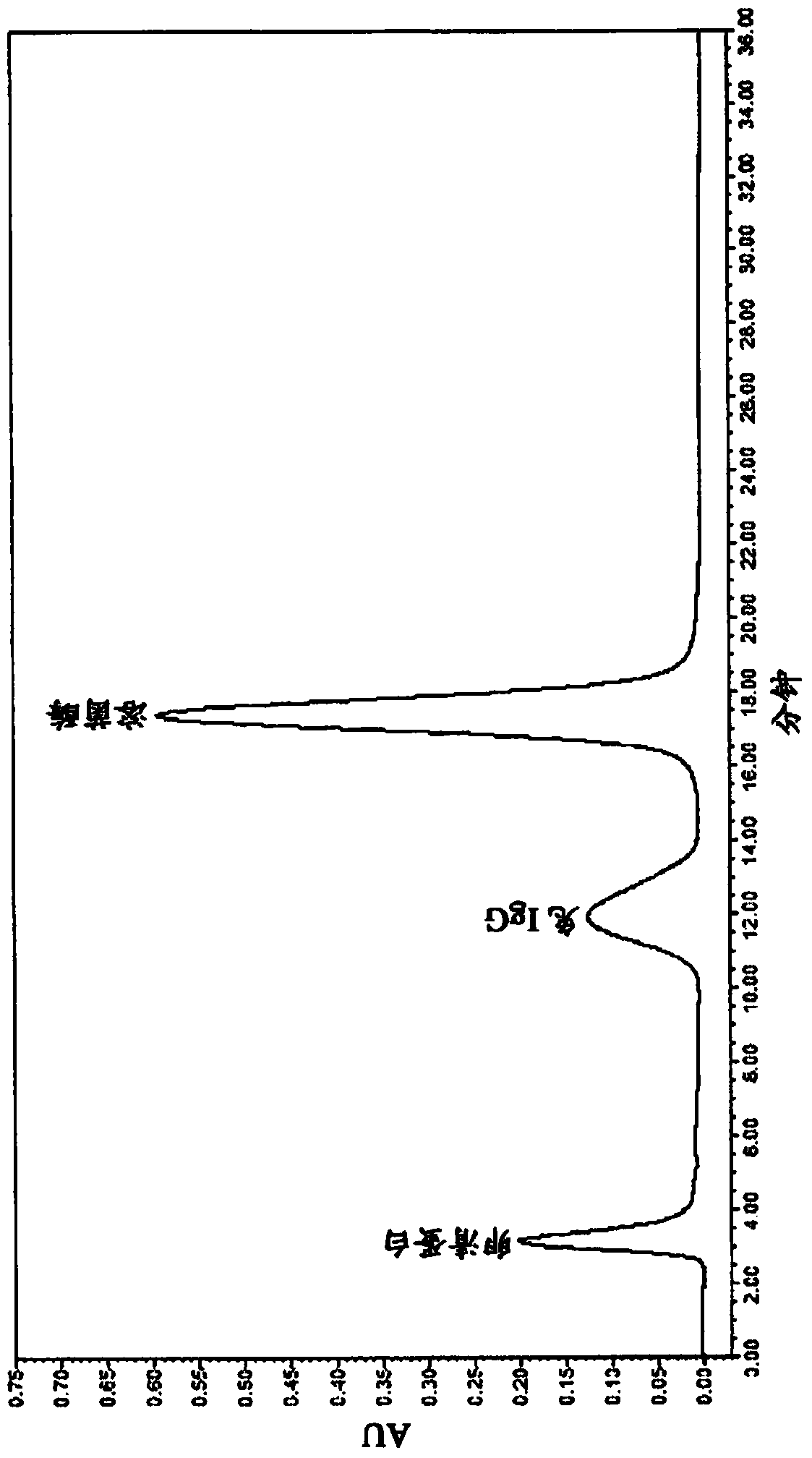

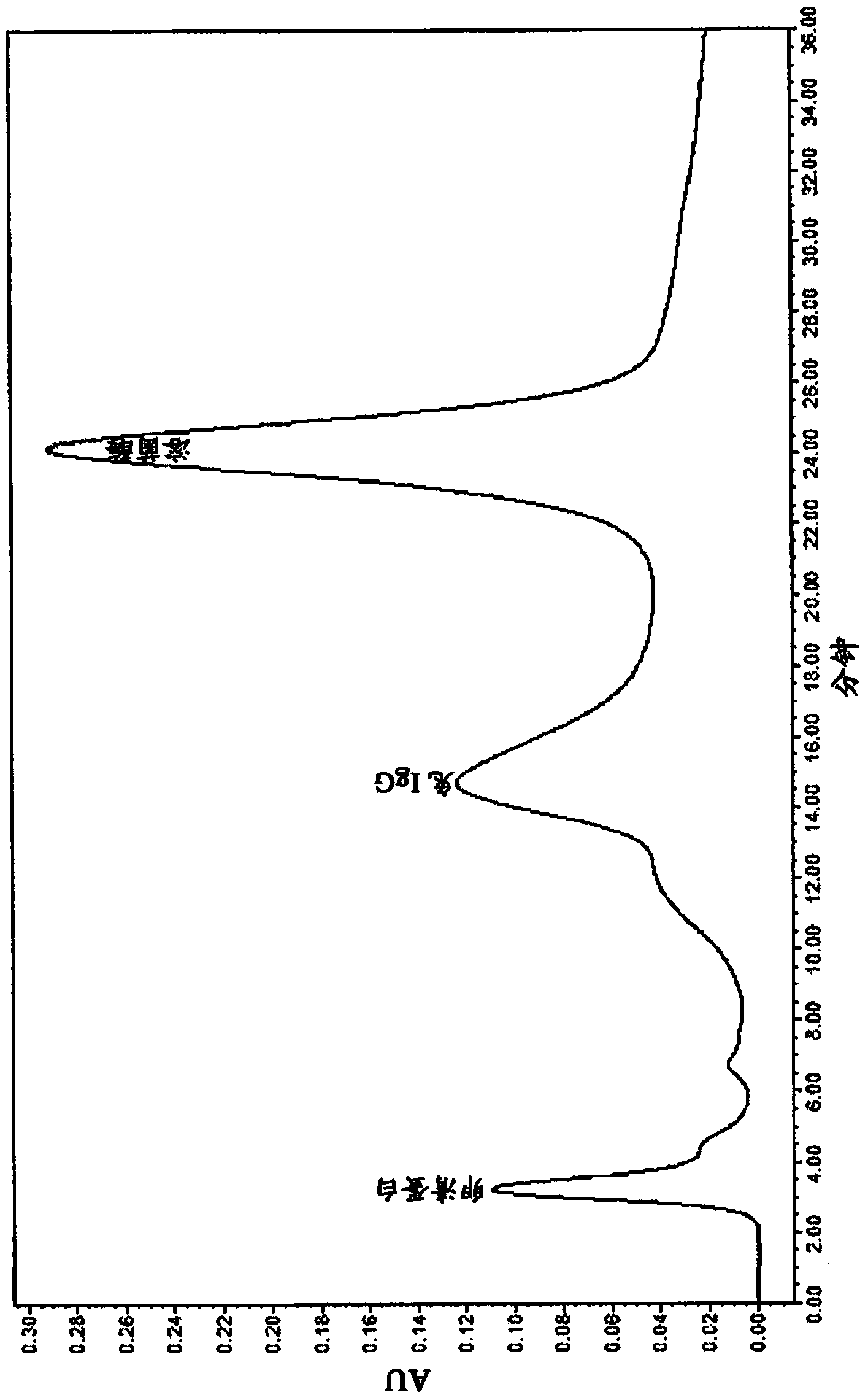

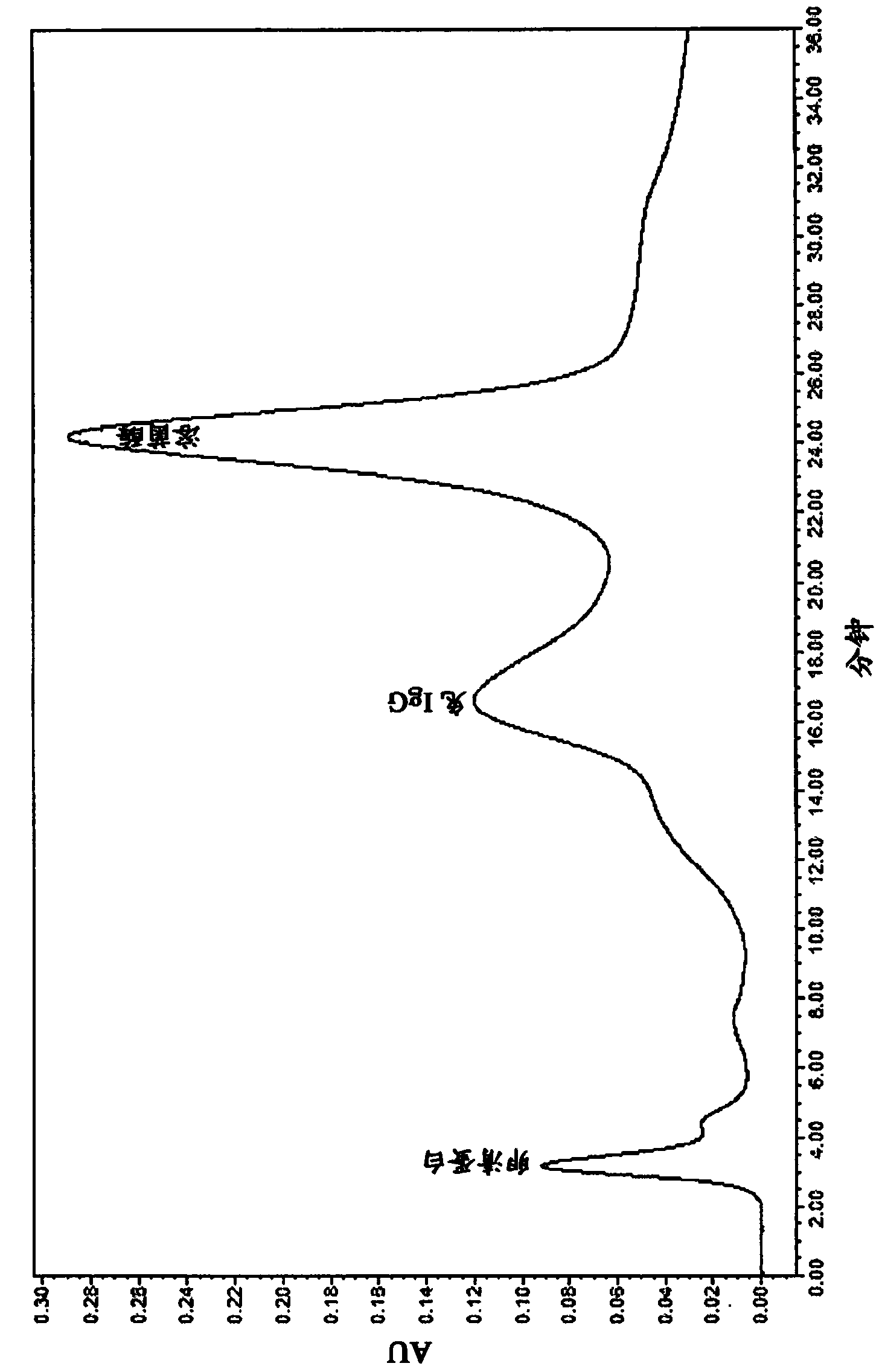

[0047] Embodiment 4: use the medium of embodiment 3 to carry out separation

[0048] The product from Example 3 was loaded onto a 100X7.75mm ID column. The column was equilibrated with 50 mM MES pH 5.6 buffer (binding buffer). After equilibration, 100 ul of binding buffer containing 2.0 mg / ml ovalbumin, 2.0 mg / ml rabbit IgG and 2.0 mg / ml lysozyme was injected into the column at 0.9 ml / min. The column was then eluted with a 0 to 100% linear gradient of 50 mM MES pH 5.6 buffer with 1.0 M NaCl (elution buffer) over 26 minutes, followed by an additional 12 minutes with 100% elution buffer . Use the medium of embodiment 3, separate according to embodiment 4, its result is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com