Special deep-bed filter for squeezing of edible oil

An edible oil and filter technology, which is applied in the directions of edible oil/fat, filtration circuit, filtration and separation, etc., can solve the problems of long separation time, long time-consuming clarification technology and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

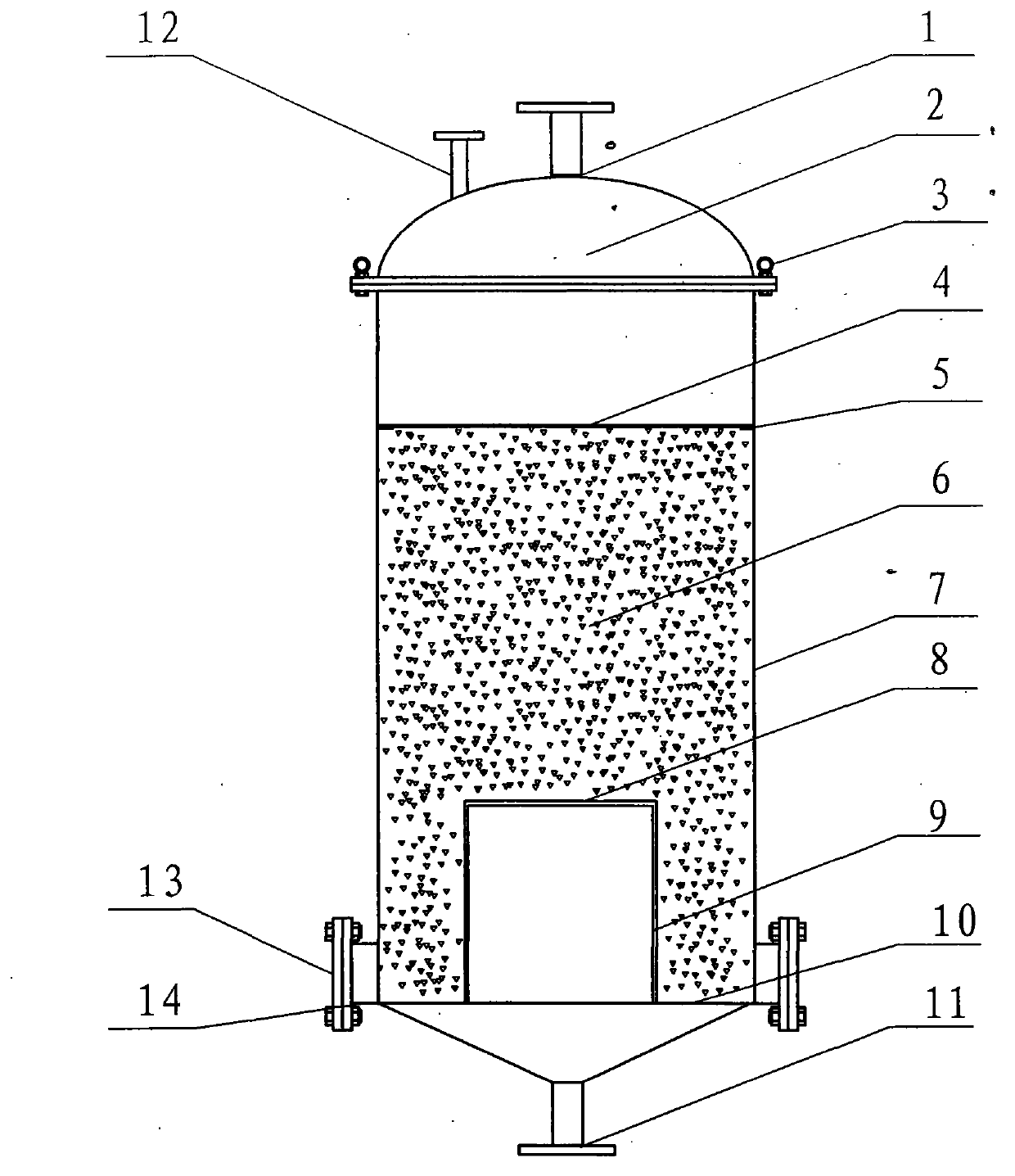

[0008] The products involved in this project are as follows: figure 1 As shown, the inside of the cylinder 7 is provided with a baffle plate 4, a connecting support 5, a filter cylinder 9, and a bearing ring plate 10; the filter cylinder and the bearing ring plate are connected as one by welding, and the filter cylinder 9 is provided with Many small holes; the filter cylinder is covered with a steel wire filter 8 to prevent the quartz sand 6 from entering the filter cylinder 9; thereby blocking the pipeline. The cylinder 7 is filled with quartz sand 6, and the bottom is carried by the filter cylinder 9 and the bearing ring plate 10; the upper part is provided with a retaining plate 4, a connection support 5, and the connection support 5 is connected with the cylinder 7; the filter cylinder 9 The bearing ring plate 10 is fixed to the cylinder body 7 by bolts. The lower end of the barrel 7 is connected with a lower cone, and the lower cone is provided with an oil outlet pipe 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com