Rotating bucket oil cylinder hoisting bracket

A bucket oil cylinder and rotating shaft technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of increasing the labor intensity of workers, delaying the processing progress, and long time consumption, so as to prevent accidental falling off and reduce the The effect of secondary operation and convenient drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

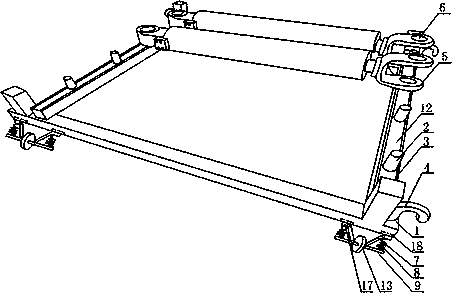

[0023] Such as Figure 1 to Figure 3 As shown, a bucket oil cylinder hoisting bracket of the present invention includes a bracket 1, cross bars 3 are installed at both ends of the bracket 1, positioning columns 2 are arranged at intervals on the cross bars 3, and inside the positioning columns 2 A screw mandrel 10 is installed, and a rubber block 11 is installed on the top of the positioning column 2. A threaded blind hole is provided on the rubber block 11, and the screw mandrel 10 is threadedly matched with the threaded blind hole. The roller 13 is provided with a shock-absorbing structure at the connection between the roller 13 and the bracket 1 , and also includes an anti-sticking pad 12 , and the anti-sticking pad 12 is arranged on the cross bar 3 . When the present invention is in use, the turning bucket oil cylinder 5 after the painting process is completed is placed on the positioning columns 2 at both ends of the support 1, and the positioning columns 2 are placed in ...

Embodiment 2

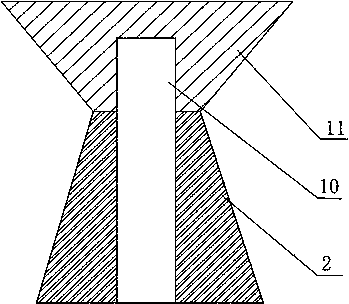

[0025] Such as figure 2 As shown, this embodiment is based on Embodiment 1, and the positioning column 2 is in the shape of a truncated cone. The bottom of the inverted frustum-shaped positioning column 2 can be fitted with the connecting hole 6 of the rotary bucket cylinder 5, and when the rotary bucket cylinder 5 is taken out or put into the positioning column 2, the positioning column 2 and the inner wall of the connecting hole 6 will not be scratched. rub.

Embodiment 3

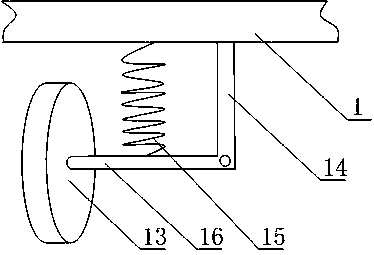

[0027] Such as figure 1 As shown, on the basis of Embodiment 1, the present embodiment includes a support column 14, the support column 14 is arranged at the bottom of the bracket 1, the rotating shaft 16 of the roller 13 is hinged to the lower end of the support column 14, and A torsion spring 15 is included, one end of the torsion spring 15 is connected to the bottom of the bracket 1 , and the other end of the torsion spring 15 is connected to the rotating shaft 16 . When the placement frame moves in the horizontal direction, if it encounters a bumpy location or bumps into an obstacle, the spring 8 on the roller 13 rotating shaft 16 can eliminate the sudden stress, avoiding the large shaking of the support 1, reducing the The bucket oil cylinder 5 ejects the positioning column 2 and slides out the possibility of the bracket 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com