Heating device for preparing fiber-reinforced polymer-based composite material

A composite material and fiber-reinforced technology, which is applied in the field of heating devices for preparing fiber-reinforced polymer-based composite materials, can solve the problems that the uniformity of heating temperature is difficult to control, unfavorable for research and development of composite materials, and unsuitable for trial production of new products. It achieves the effect of flexible heating method, simple structure and improved impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

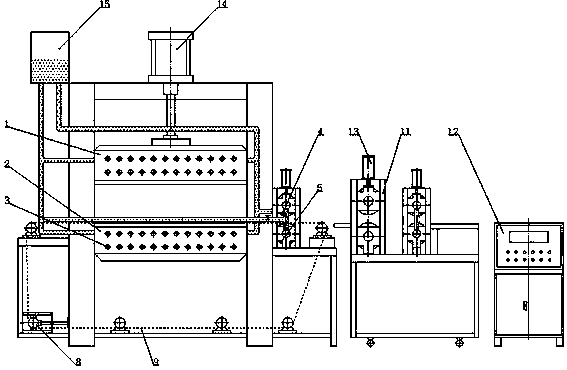

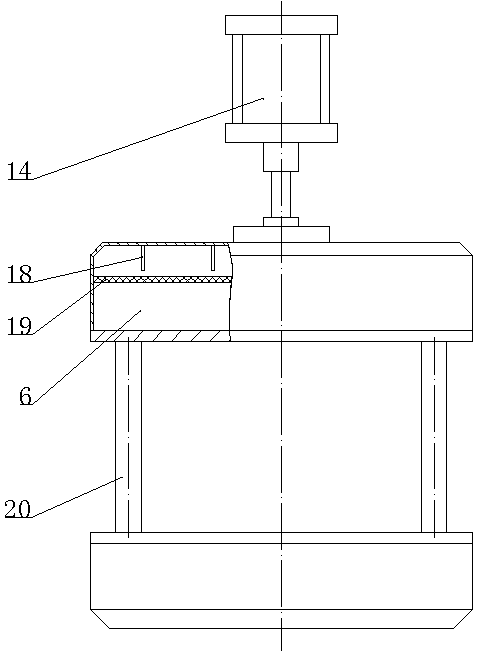

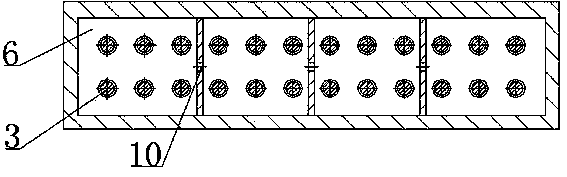

[0028] Such as figure 1 As shown, a heating device for preparing fiber-reinforced polymer-based composite materials, including a heating platen combination consisting of an upper heating platen 1 and a lower heating platen 2, and a conveyor belt passing between the upper heating platen 1 and the lower heating platen 2 9. The conveyor belt 9 adopts a Teflon conveyor belt, and a Teflon tensioning device 8 is provided on the conveyor belt 9. The heating device is also provided with an electrical control cabinet 12, and a main hydraulic cylinder 14 is provided above the upper heating platen 1. The piston rod of the cylinder 14 is connected with the upper heating platen 1, and the outer side of the transmission end of the conveyor belt 9 is provided with a shaping pressure roller assembly 11 controlled by a gap adjustment hydraulic cylinder 13, and an upper heating plate assembly and the shaping pressure roller assembly 11 are provided. The pressure roller 4 and the lower heating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com