Printing decoration film with stereoscopic effect, and its decoration plastic product

A technology of three-dimensional effect and decorative film, which is applied to the printing of special varieties of printed matter, special decorative structures, and techniques for producing decorative surface effects, etc., and can solve problems such as unrevealed three-dimensional visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

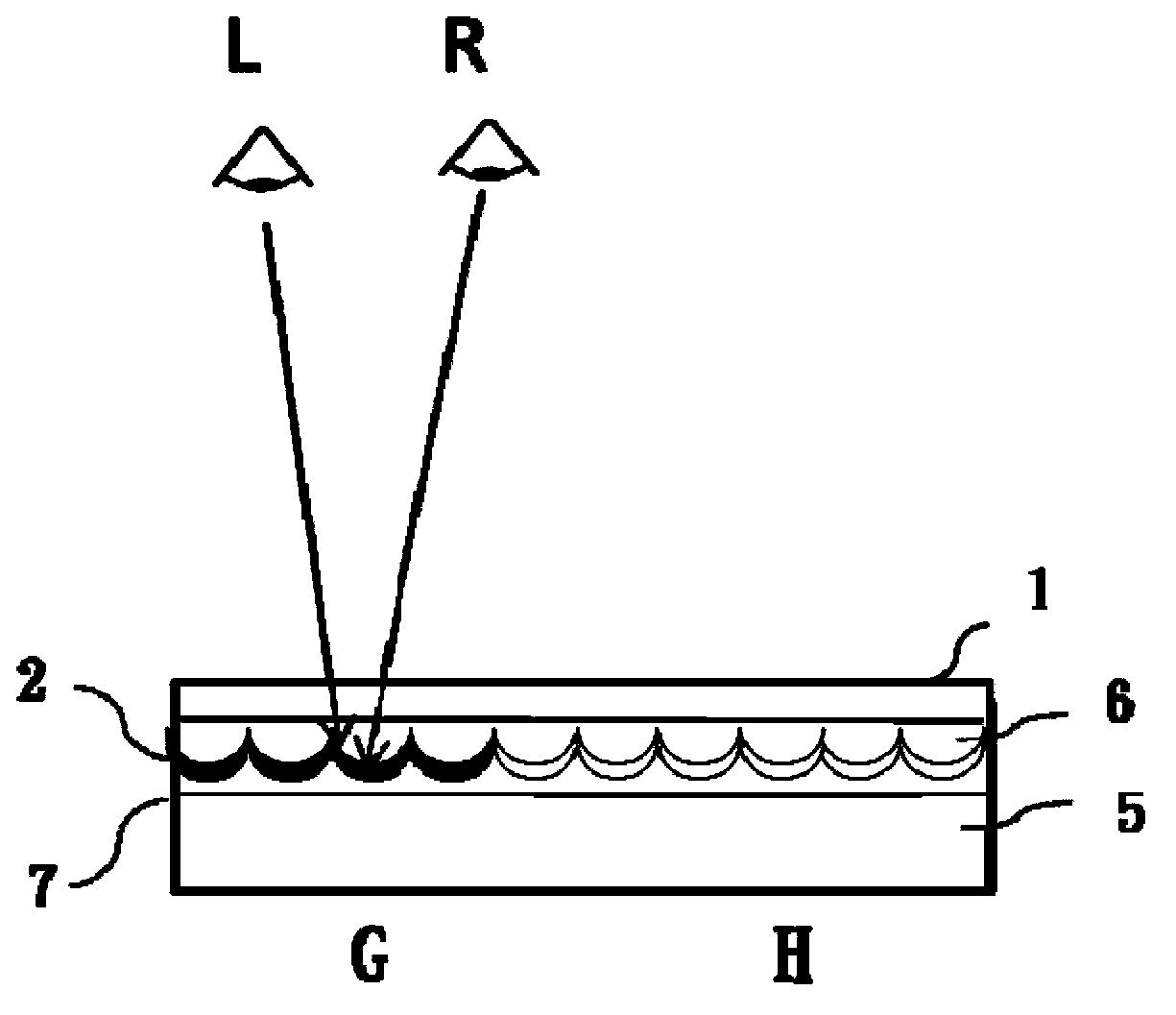

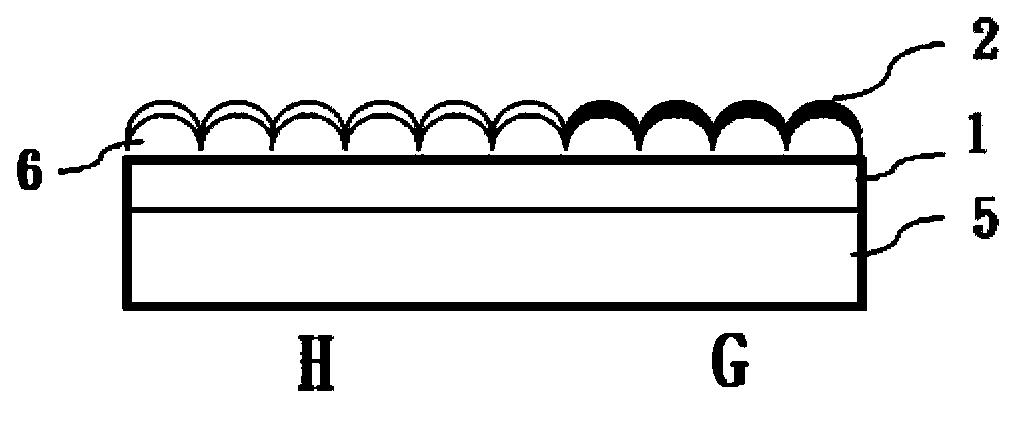

[0067] Using a transparent sheet with a hemispherical lens on one side, the Korean company Kolon's MLF The hemispherical lens film, its transparent sheet is a 188 micron thick polyethylene terephthalate (PET) optical film, with a heat distortion temperature of 120°C, and contains a 42 micron high hemispherical lens, which is ultraviolet Hardened acrylic hemispherical lens, heat deflection temperature 180°C. 120 centimeters long and 80 centimeters wide, its hemispherical lenses have a density of about 70,000 lenses per square inch. An industrial-grade digital inkjet printing machine exposed to ultraviolet rays, printing a printing layer 2 with a precise pattern on the surface of the hemispherical lens, with a pattern precision of 600 dots per inch (equivalent to 360,000 dots per square inch), thus forming Three-dimensional printed decorative film. The printing resolution of this example is 5 times of the density of the lens, and the obtained decorative film has excellent thr...

Embodiment 2

[0069] Utilizes an 80 micron thick triacetate optical film with a heat deflection temperature of 80°C containing 20 micron high hemispherical lenses, which are UV hardened hemispherical lenses, which are Epoxy resin (Epoxy) heat distortion temperature 250 ° C. 120 centimeters long and 80 centimeters wide, its hemispherical lenses have a density of about 50,000 lenses per square inch. An industrial-grade digital inkjet printing machine exposed to ultraviolet rays, printing a printing layer 2 with a precise pattern on the surface of the hemispherical lens, with a pattern precision of 800 dots per inch (equivalent to 640,000 dots per square inch), thus forming Three-dimensional printed decorative film. The printing resolution of this example is 13 times the density of the lens, and the obtained decorative film has excellent three-dimensional printing effect and pattern resolution.

Embodiment 3

[0071] Using an acrylic sheet with hemispherical lenses on one side, 120 cm long and 80 cm wide, the density of the hemispherical lenses is 70,000 lenses per square inch. Like the printing precision and printing process of Embodiment 1, the printing layer 2 printed with precise patterns has a pattern precision of 1300 dots per inch (equivalent to 1.69 million dots per square inch), thus forming a three-dimensional printed decoration membrane. The printing resolution of this example is 24 times the density of the lens, and the obtained decorative film has an excellent three-dimensional printing effect, but the pattern resolution is obviously reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com