Aluminum metal smelting slag reuse method

An aluminum metal and slag technology is applied in the field of aluminum metal smelting slag recycling, which can solve the problems of poor surface fineness, bursting, and cracking of refractory rough embryos, etc. Reduced, fast processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

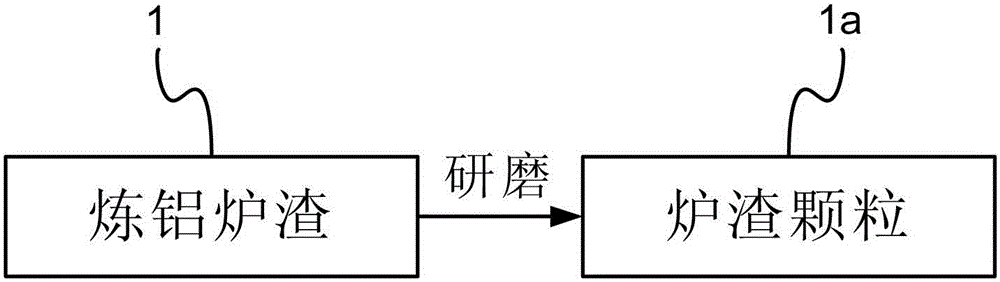

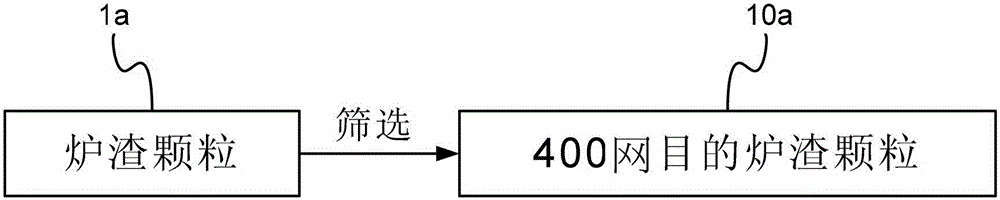

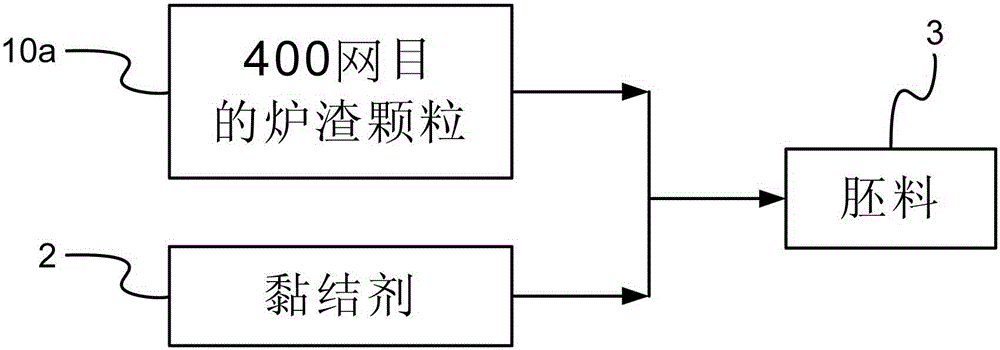

[0043] see Figure 1 to Figure 5 , are respectively a schematic diagram of Step 1 of the present invention, a schematic diagram of Step 2 of the present invention, a schematic diagram of Step 3 of the present invention, a schematic diagram of Step 4 of the present invention, and a schematic diagram of Step 5 of the present invention. As shown in the figure, the present invention is a method for reusing aluminum metal smelting slag, which at least includes the following steps:

[0044] Step 1: Grinding the aluminum smelting slag 1 into granules to form slag particles 1a.

[0045] Step 2: Screen the slag particles 1a with a particle size between 200 mesh (mesh) and 400 mesh. In the embodiment of the present invention, the slag particles 10a with a mesh size of 400 mesh are selected as the raw material for refractory bricks. For the slag particles with a mesh size of 400 The particles 10a are subjected to a nitrogen content detection procedure to confirm that the nitrogen conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com