Preparation method of organic/inorganic hybrid impervious dense water-proofing agent

A technology of waterproofing agent and organosilicon compound, which is applied in the field of new chemical building materials, can solve the problems of poor durability of waterproofing layer, poor waterproofing and impermeability, and price confusion, and achieve dense structure of waterproofing layer, enhanced impermeability, and openness short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Mix 0.5 parts of NP-200, 0.5 parts of sodium lauryl sulfate, 15 parts of silica fume, and 53 parts of water at a high speed of 150 rpm for 30 minutes. Then add 30 parts of methyltriethoxysilane, 0.5 part of ethylene glycol, and 0.5 part of Aerosil, and stir to obtain a hybrid solution.

[0027] 2. Then, at a stirring rate of 30rpm, add 65 parts by mass of the prepared hybrid solution, 25.2 parts by mass of water, 1 part by mass of DP-2001, 0.3 parts by mass of DF-2000, 5 parts by mass of Rheoplus4105, and 3 parts by mass of diethanolamine to the reactor in sequence. Parts by mass, 5 parts by mass of oleic acid, after stirring evenly, finally add 0.5 parts by mass of Alscoap, stir well and evenly, then discharge and pack to obtain impermeable dense waterproofing agent. Embodiment two

Embodiment 2

[0028] 1. Mix 1.5 parts of OP-20, 30.5 parts of Emulsogen EPA07, 20 parts of silica fume, and 51.5 parts of water under high-speed stirring at 250 rpm for 30 minutes. Then add 25 parts of aminopropyltriethoxysilane, 0.5 part of ethylene glycol, and 1 part of Celatom, and stir to obtain a hybrid solution.

[0029] 2. Then, at a stirring rate of 45rpm, add 55 parts by mass of the prepared hybrid solution, 21.5 parts by mass of water, 3 parts by mass of DP-2000, 0.5 parts by mass of DF-2000, 7 parts by mass of Rheoplus4107, triethanolamine 2 Parts by mass, 10 parts by mass of sodium stearate, after stirring evenly, finally add 1 part by mass of Alscoap, fully stir evenly, then discharge and pack to obtain impermeable dense waterproofing agent.

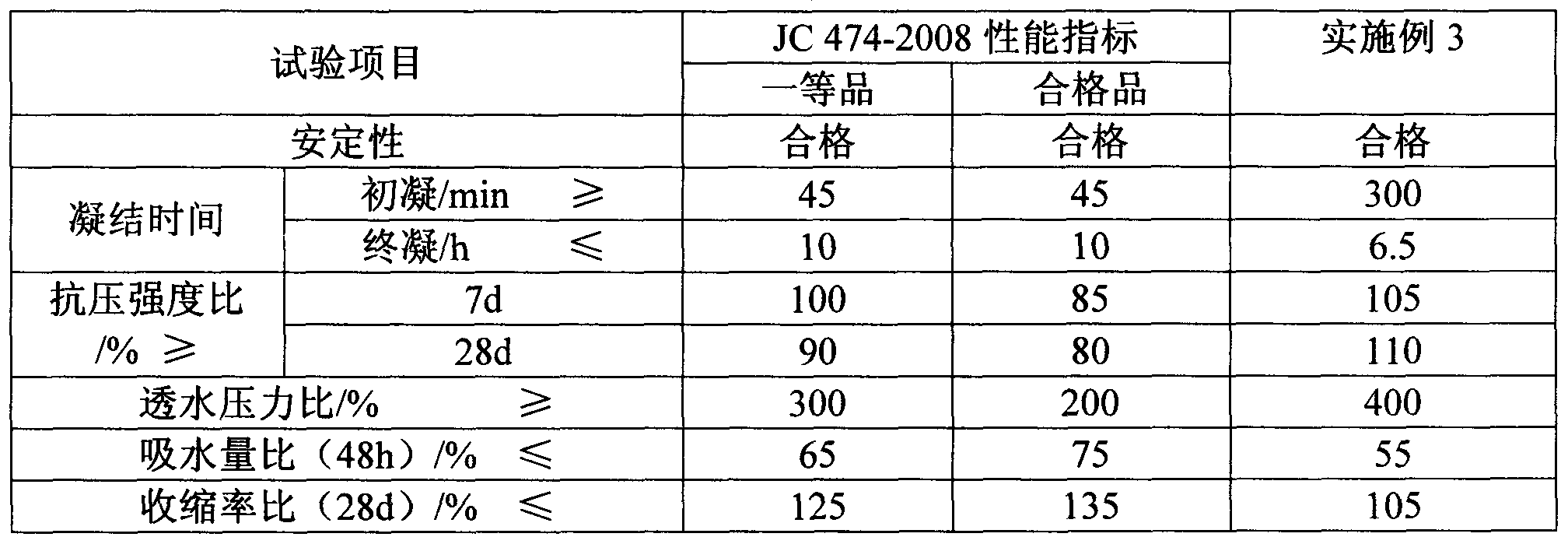

Embodiment 3

[0031] 1. Mix 2 parts of NP-20, 0.5 parts of Emulsogen LCN407, 30 parts of silica fume, and 36 parts of water under high-speed stirring at 250 rpm for 30 minutes. Then add 30 parts of n-octyltriethoxysilane, 0.5 parts of propylene glycol, and 2001 parts of Aerosil, and stir to obtain a hybrid solution.

[0032] 2. Then, at a stirring rate of 60rpm, add 70 parts by mass of the prepared hybrid solution, 8.5 parts by mass of water, 5 parts by mass of DP-2005, 0.5 parts by mass of DF-2000, 5 parts by mass of Rheoplus4105, and 3 parts by mass of triethanolamine to the reactor in sequence. Parts by mass, 7 parts by mass of oleic acid, after stirring evenly, finally add 1 part by mass of Alscoap, stir well and evenly, then discharge and pack to obtain impermeable dense waterproofing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com