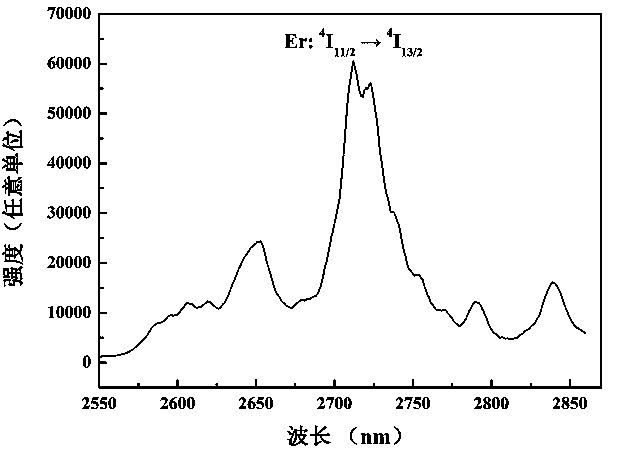

Preparation method of Er<3+>, Pr<3+> and Tm<3+>-doped yttrium lanthanum oxidetransparent ceramic for lasers

A technology of lanthanum yttrium oxide and transparent ceramics, which is applied in the field of special ceramics manufacturing technology, and can solve the problems of difficult to obtain high-efficiency 2.7μm laser and long energy level life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The process and steps of the present embodiment are described as follows:

[0018] 1. Using high-purity Er 2 o 3 、Pr 6 o 11 、Tm 2 o 3 , La 2 o 3 and Y 2 o 3 Nano powder is raw material, and the molar ratio of each powder is according to chemical molecular formula (Er x PR y T m z Y 0.9-x-y-z La 0.1 ) 2 o 3 , where x = 0.02, y = 0.02, z = 0.02;

[0019] 2. Stir and mix the powder raw materials prepared according to the above formula, dissolve the mixture in absolute ethanol, and mix and grind for 8 hours with a ball mill. During ball milling, the mass ratio of the ball mill to the powder is 1:2, and the ball milling speed is 50 rpm;

[0020]3. Dry the ball-milled powder in an oven, then pre-fire at 1200°C for 8-10 hours;

[0021] 4. Granulate the mixture after pre-burning, and press it into a sheet-like sample under 200MPa cold isostatic pressing;

[0022] 5. Place the above sample in a hydrogen furnace or a vacuum furnace for sintering, the sintering ...

Embodiment 2

[0024] The processing steps of the present embodiment are exactly the same as the above-mentioned embodiment 1, and the difference is (Er x PR y T m z Y 0.9-x-y-z La 0.1 ) 2 o 3 In the formula, x=0.01, y=0.01, z=0.01; sintering temperature 1600 ℃, holding time 45h, obtain dense (Er 0.01 PR 0.01 T m 0.01 Y 0.87 La 0.1 ) 2 o 3 Transparent ceramic.

Embodiment 3

[0026] The processing steps of the present embodiment are exactly the same as the above-mentioned embodiment 1, and the difference is (Er x PR y T m z Y 0.9-x-y-z La 0.1 ) 2 o 3 x=0.05 in the formula, y=0.05, z=0.05; Sintering temperature 1630 ℃, holding time 40h, obtain dense (Er 0.05 PR 0.05 T m 0.05 Y 0.75 La 0.1 ) 2 o 3 Transparent ceramic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com