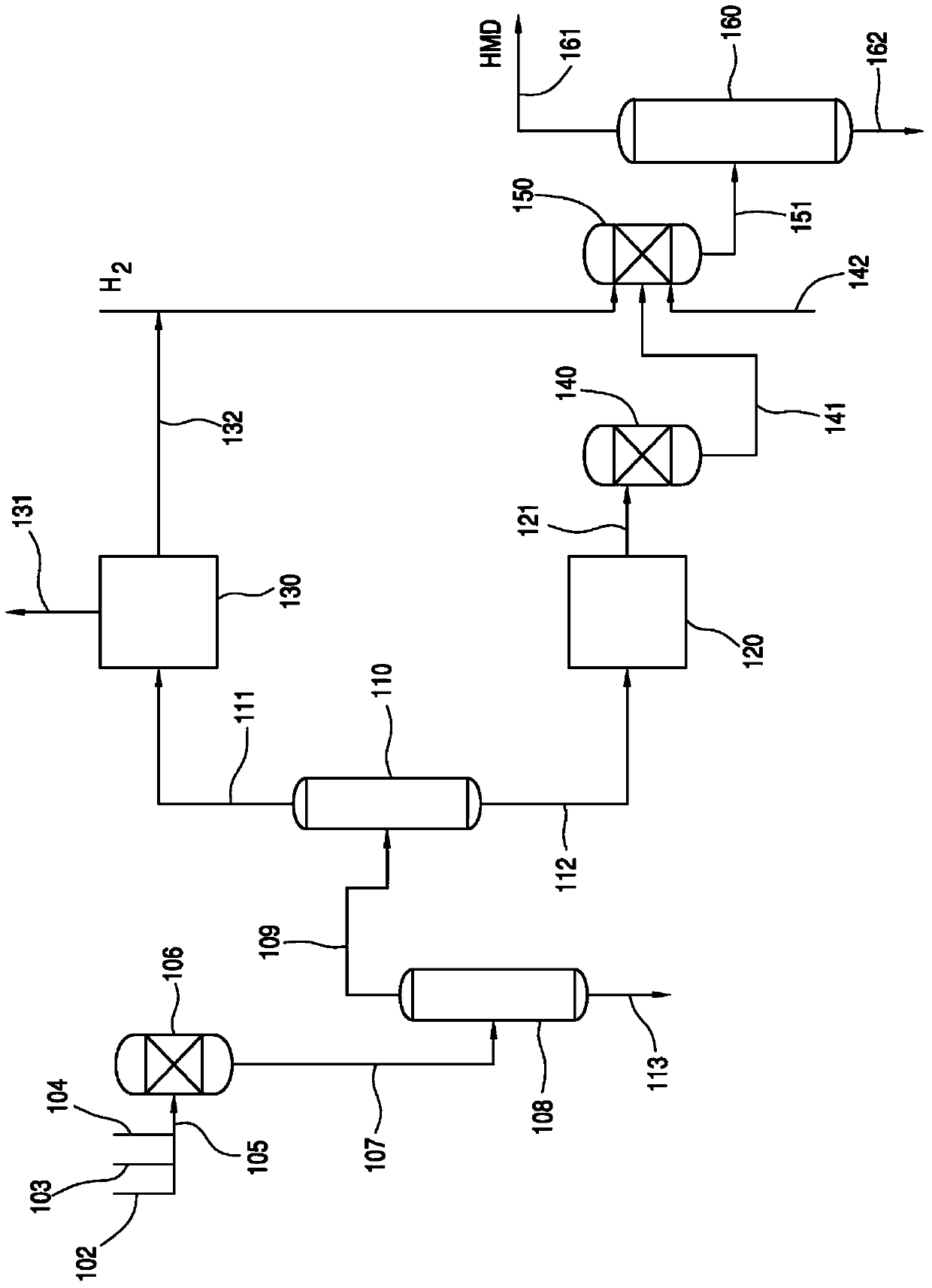

Integrated process for hexamethylenediamine production

A technology of hexamethylenediamine and methane gas, which is applied in chemical instruments and methods, preparation of amino compounds, preparation/purification/separation of hydrogen cyanide, and can solve problems that have not been disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Pure oxygen, ammonia-containing gas, and methane-containing gas are combined to form a ternary gas mixture. In the ternary gas mixture, the molar ratio of ammonia to oxygen was 1.3:1 and the molar ratio of methane to oxygen was 1.2:1. A ternary gas mixture comprising 27 to 29.5 vol% oxygen is reacted in the presence of a platinum / rhodium catalyst to form a crude hydrogen cyanide product comprising 34 to 36 vol% hydrogen. Hydrogen gas is formed during the reaction. The crude hydrogen cyanide product is removed from the reactor and sent to an ammonia removal unit to separate residual ammonia from the crude hydrogen cyanide product. The crude hydrogen cyanide product is then sent to an adsorber to form a waste gas and hydrogen cyanide product stream. The exhaust gas had the composition shown in Table 3 (Oxygen Andrussow method) and was then compressed to a pressure of 2275 kPa and sent to the PSA unit. The PSA unit comprises four beds, each comprising activated carbon a...

Embodiment 2

[0084] The hydrogen stream from Example 1 was introduced into the HMD production system comprising the HMD reactor for the production of hydrogenated AND. The hydrogen stream may be pressurized to a pressure of at least 2100 kPa prior to entering the HMD production system. HMD production methods are described in US Patent 3398195. On a molar basis, the hydrogen flow is capable of providing at least 20% of the hydrogen required to hydrogenate ADN to form HMD or a combination of HMD and ACN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com