A copper-reducing etching solution for printed circuit boards

A printed circuit board, copper etching technology, applied in the chemical industry, can solve the problems of increasing cost and long time, and achieve the effect of reducing production cost and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

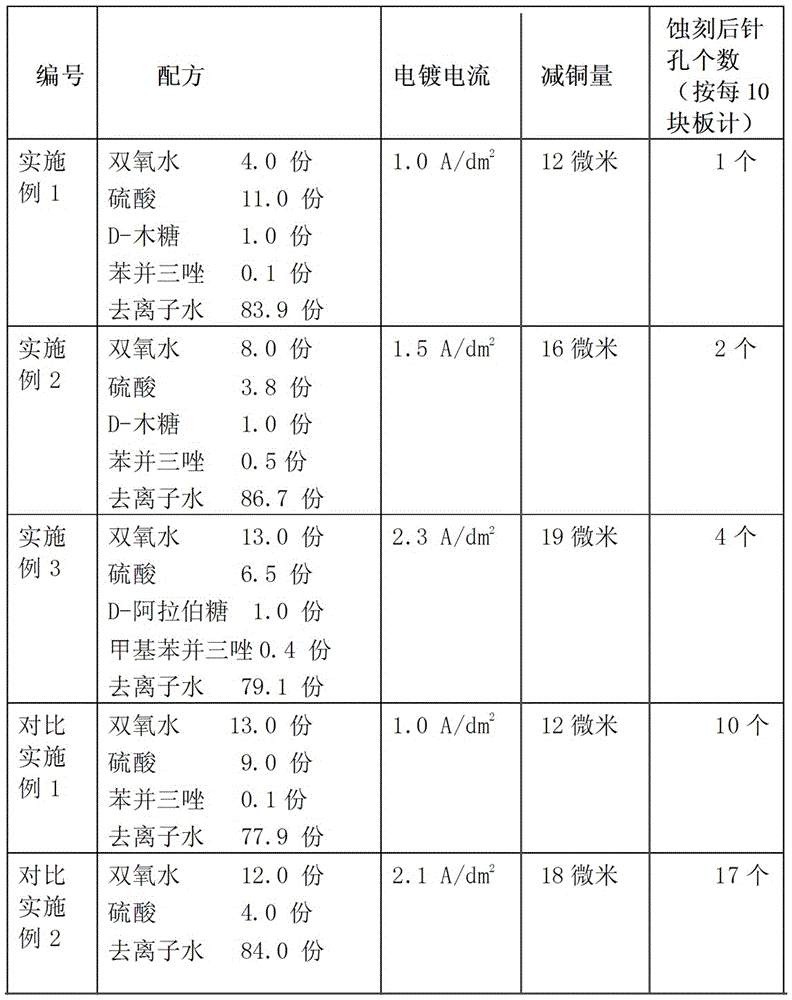

Embodiment 1

[0015] Use the potion of the present invention containing 4.0 parts of hydrogen peroxide, 11.0 parts of sulfuric acid, 1.0 parts of D-xylose, 0.1 parts of benzotriazole, and 83.9 parts of deionized water to etch the plate for copper reduction.

Embodiment 2

[0017] Use the potion of the present invention containing 8.0 parts of hydrogen peroxide, 3.8 parts of sulfuric acid, 1.0 parts of D-xylose, 0.5 parts of benzotriazole, and 86.7 parts of deionized water to etch the plate for copper reduction.

Embodiment 3

[0019] Use the potion of the present invention containing 13.0 parts of hydrogen peroxide, 6.5 parts of sulfuric acid, 1.0 part of D-arabinose, 0.4 parts of methyl benzotriazole, and 79.1 parts of deionized water to etch the plate for copper reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com