Direct-through-cold-and-hot-bridge-free multi-row-hole multifunctional hollow brick

A cold and hot bridge, multi-functional technology, used in building components, walls, buildings, etc., can solve the problems of insufficient strength, unmanufacturable hole pattern, low ignition point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Below in conjunction with accompanying drawing and embodiment the present invention will be further described.

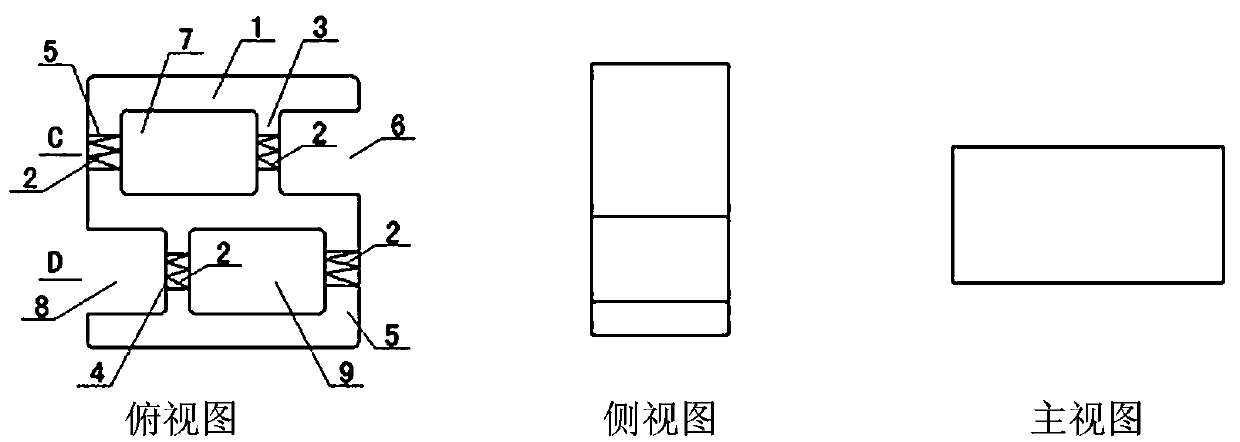

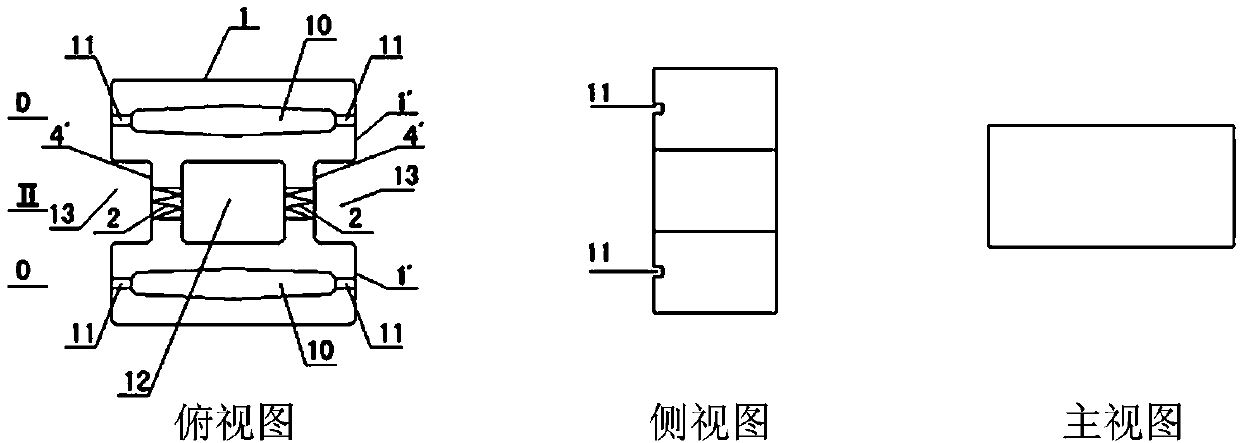

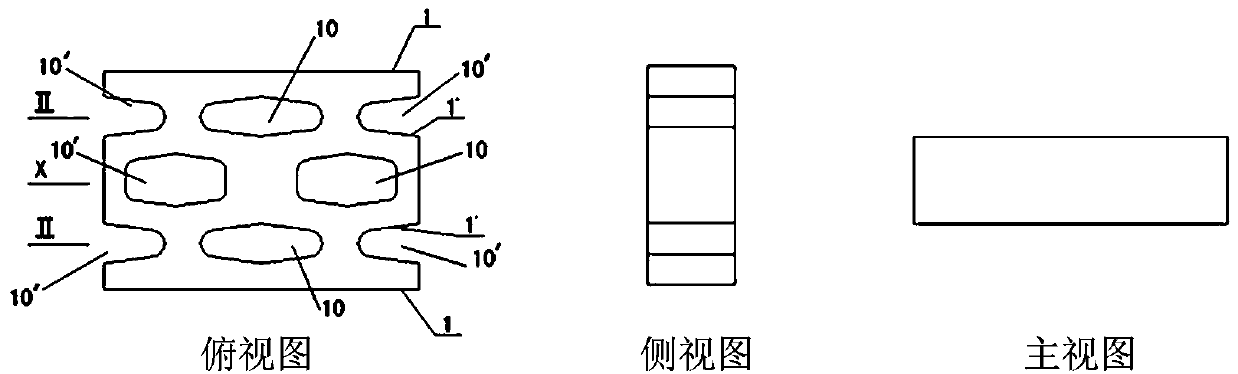

[0092] As shown in the accompanying drawings, the present invention includes a brick body, the brick body includes inner and outer walls (1) and multiple rows of holes in the same head-sealed type, numbered as (5) in "C", and rectangular open side ribs (3) ) numbered "D" in (4), (5) formed the closed opening (7), (9) and the opening hole (6), (8) one right and one left, or one left and one right or repeated In the same block with multiple rows of holes, such as figure 1 The "S" opening structure formed by two rows of holes, one upper, one lower, one right, and one left; Figure 5 In the four rows of holes, the upper, right (6), lower, left (8) open holes make the block have no direct cold and heat bridge; Figure 10 , six Row of holes; Figure 13 , Eight row of holes, repeating the hole pattern in the same multi-row hole block pattern as Figure 15 (n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com