Water mixing type exhaust gas recirculation system and engine with the same

A recirculation system and hybrid technology, which is applied in the direction of exhaust gas recirculation, engine components, combustion engines, etc., can solve the problems of high content of harmful components in engine exhaust, many soot particles, and insufficient utilization of residual calorific value of exhaust gas, etc. , to achieve the effect of improving emission cleanliness, reducing harmful components, and reducing emission particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

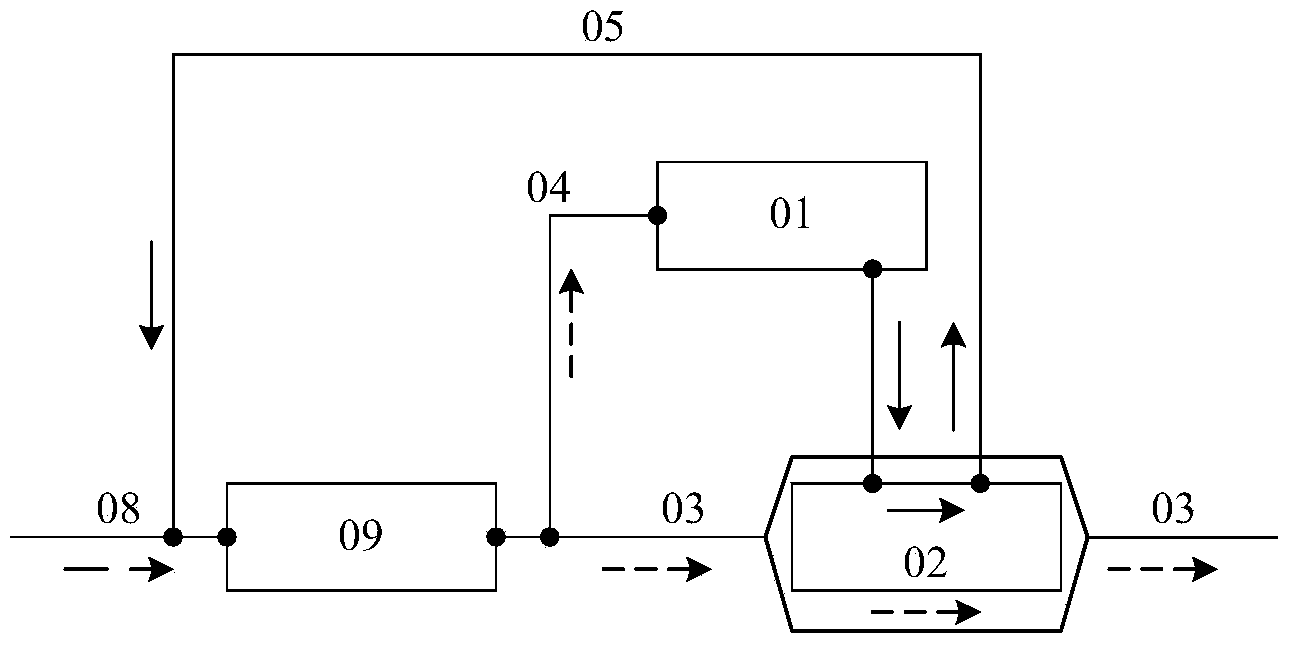

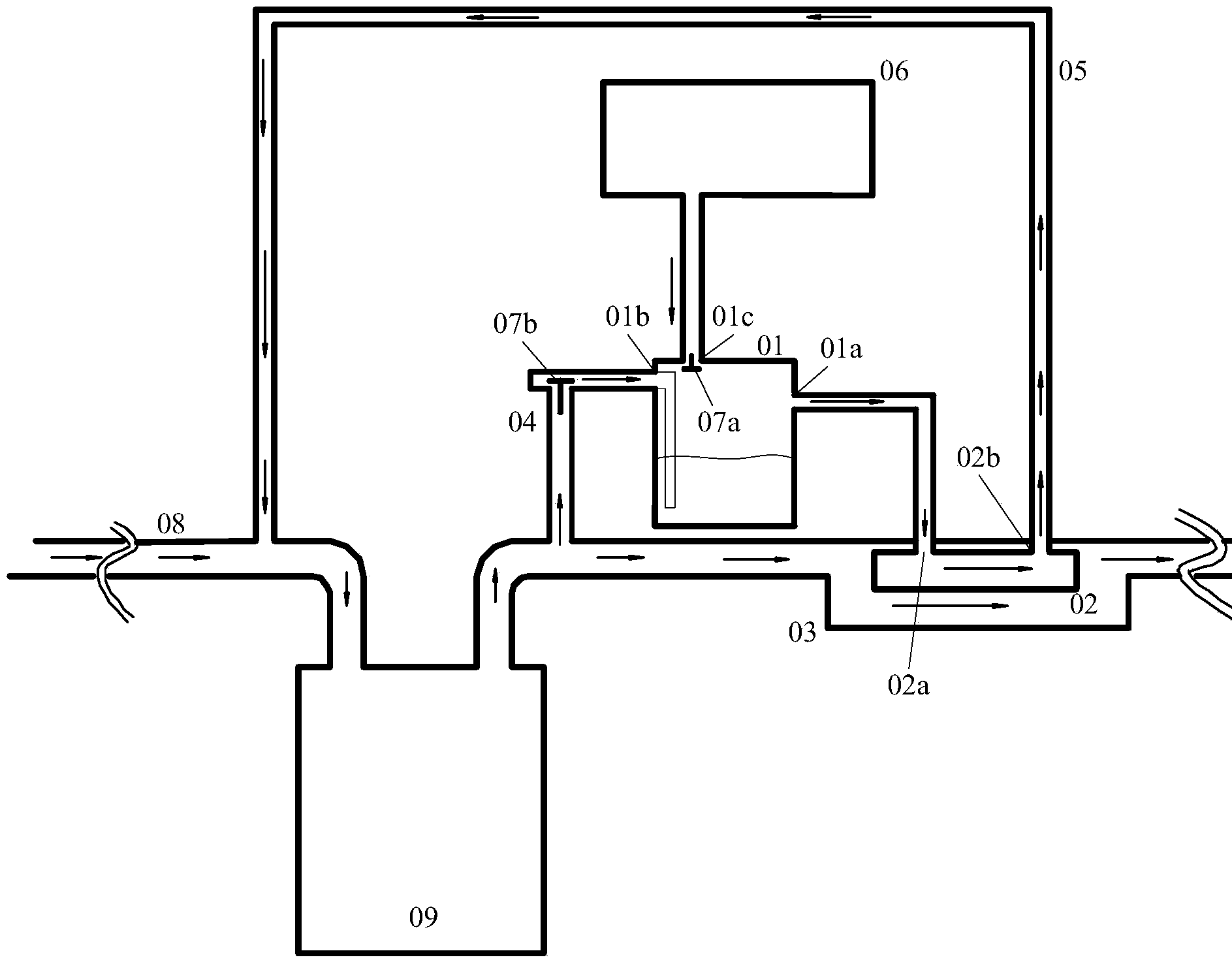

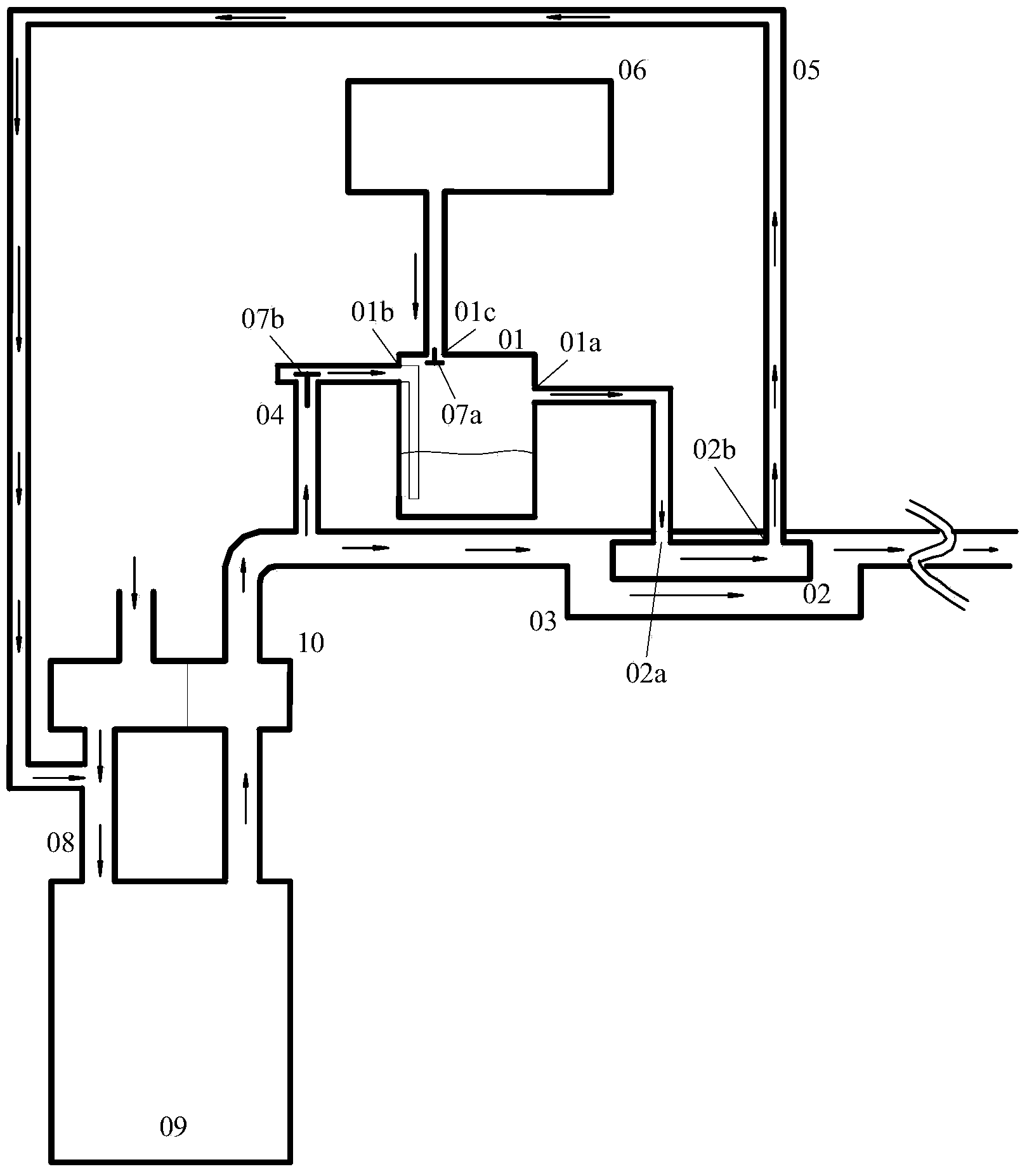

[0039] Such as figure 1 As shown, the present invention includes a water-gas mixing device 01, a heat exchanger 02, an exhaust pipe 03, an exhaust manifold 04 and a steam pipe 05;

[0040] Water-air mixing device 01 is used to fully mix high-calorific-value tail gas with liquid water, increase the air solubility of liquid water, and rapidly increase the preheating temperature of liquid water;

[0041] The heat exchanger 02 is used to heat the injected liquid water to the corresponding temperature and discharge the water vapor;

[0042] Exhaust gas exhaust pipe 03 is used for the main exhaust channel of high calorific value exhaust gas of the engine, and provides heat source for heat exchanger 02;

[0043] Exhaust manifold 04, used for the secondary exhaust channel of engine high calorific value exhaust, provides heat source and pressure for water-air mixing device 01;

[0044] The steam pipe 05 is used as a channel for delivering water vapor to the intake pipe 08 of the engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com