1.5-level transonic axial-flow air compressor testing apparatus

A technology of axial flow compressor and test device, which is applied in the field of test machines, to achieve the effects of increased manufacturing difficulty, improved sensitivity, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

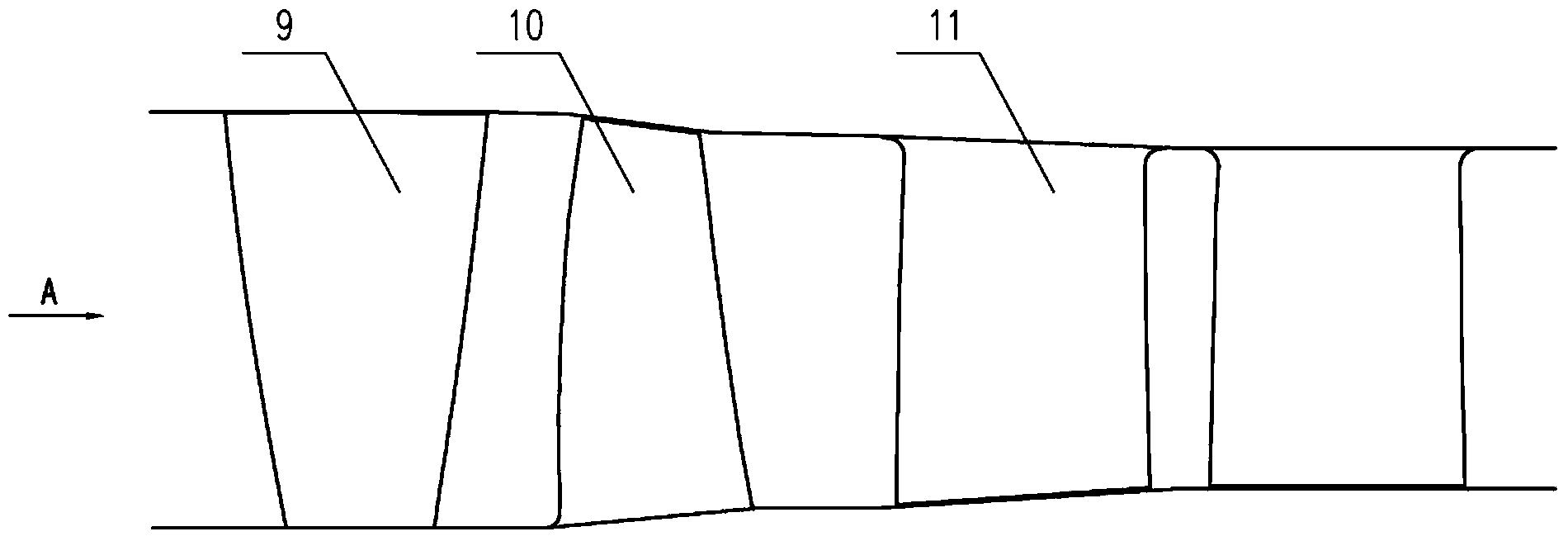

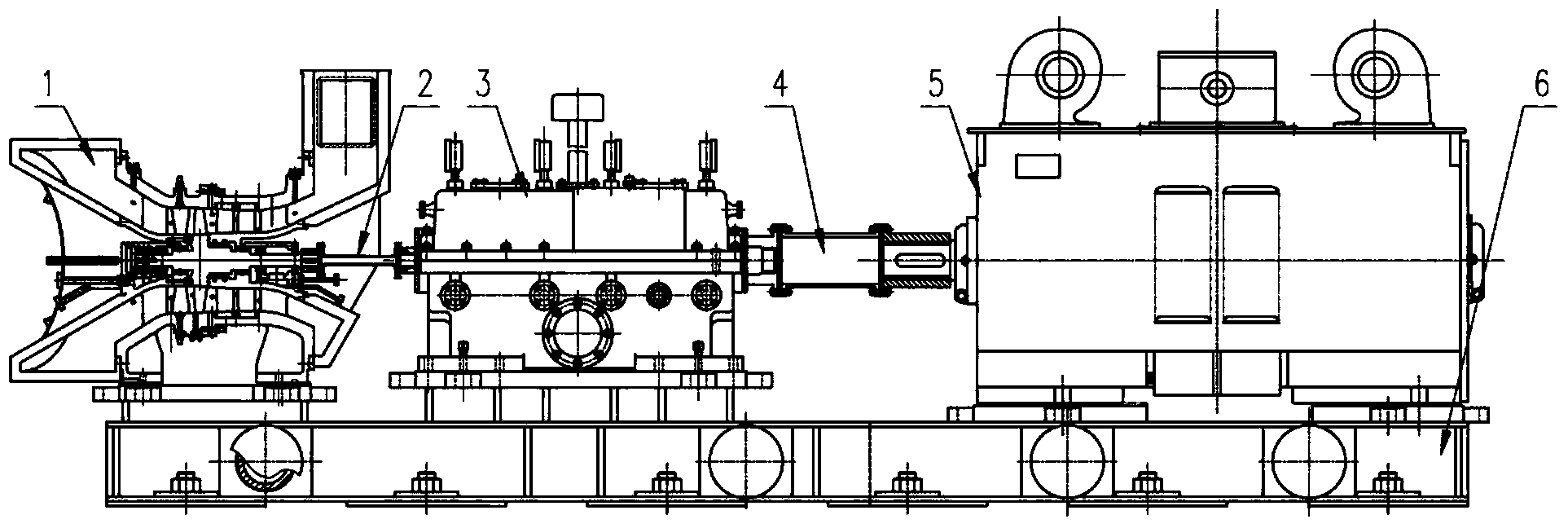

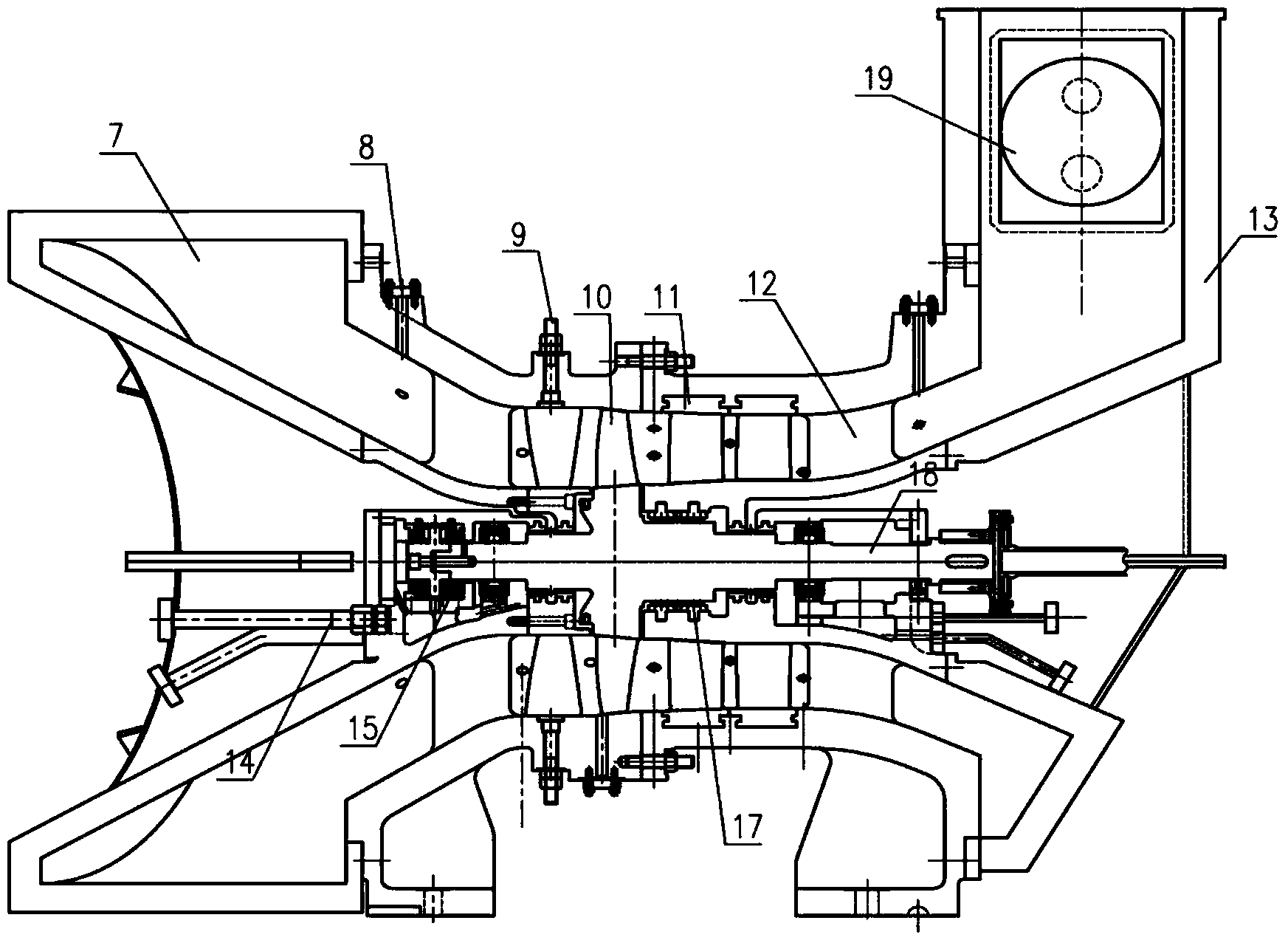

[0034] This embodiment describes as Figure 1-8 As shown, the 1.5-stage transonic axial flow compressor test device provided in this embodiment mainly includes a compressor 1, a high-speed diaphragm coupling 2, a gearbox 3, a low-speed end coupling 4, a motor 5, and a common chassis 6 , the motor 5 drives the gearbox 3 to rotate through the low-speed coupling 4; after the gearbox 3 speeds up, it drives the compressor 1 through the high-speed diaphragm coupling 2.

[0035] Among them, the compressor 1 is the most complex and core component. The compressor 1 mainly includes a flow part, an air inlet 7, an air outlet 13, a rotor 18, a lubrication system 14, a bearing system 15, a sealing system 17 and a measurement system 8. When the engine 1 is working, the air enters the flow part from the air inlet 7, and then is discharged into the atmosphere through the air outlet 13; the rotor 18 is supported by the bearing system 15 and lubricated and cooled by the lubrication system 14; i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com