A dedicated collection device for glass silica sand

A collection device, glass silicon technology, applied in the direction of sampling devices, etc., can solve the problems of reducing the quality of material composition analysis, not conducive to energy saving and emission reduction, labor and time-consuming, etc., and achieve the effect of simple structure, labor cost saving, and convenient sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

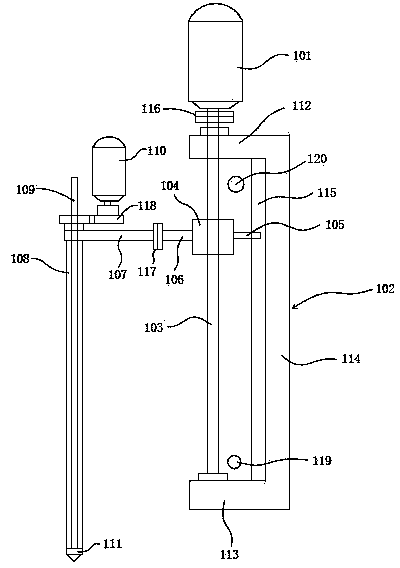

[0031] figure 1 A schematic structural diagram of a dedicated glass silica sand collection device according to an embodiment of the present invention is shown. refer to figure 1 The embodiment of a special glass silica sand collection device shown includes a running motor 101, a support platform 102, a screw rod 103, a nut 104, a trolley 105, a first connecting pipe 106, a second connecting pipe 107, a collecting pipe 108, and a collecting rod 109 , collecting motor 110 and drill bit 111; Described support platform 102 comprises the top plate 112 of horizontal installation, the base plate 113 of horizontal installation and the support plate 114 of vertical installation, and described support plate 114 is positioned at described top plate 112 and described base plate 113 between the two ends of the top pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com