Method for measuring expansibility of catalytic converter seal gasket

A catalytic converter and sealing gasket technology, applied in the direction of material thermal expansion coefficient, etc., can solve the problems of different, no statutory tools and detection methods for catalytic converter sealing gasket detection, large risks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

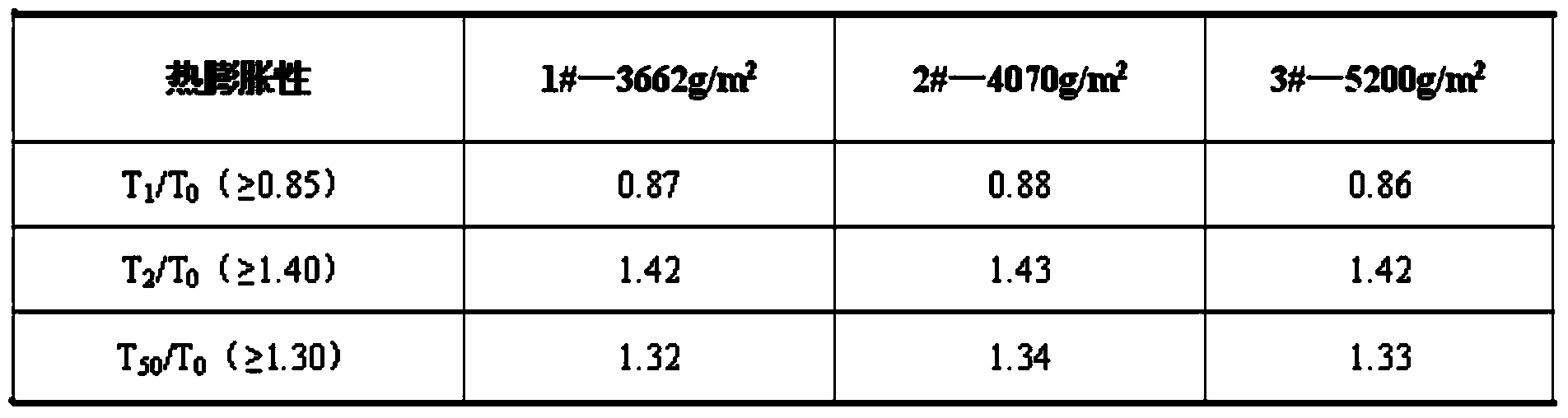

[0038] (1) Sampling, select a piece of 100×100mm expansion sealing gasket with a grammage of 3662g / m2 and a thickness of 5.4mm;

[0039] (2) Make a sample, use a die-cutting die to punch the intumescent sealing gasket into a test sample with a diameter of 11mm, and mark it as a 1# sample;

[0040] (3) Place the sample, place the 1# sample under the movable end of the quartz glass rod in the thermal expansion analyzer, and provide a pressure of 1345g above the quartz glass rod;

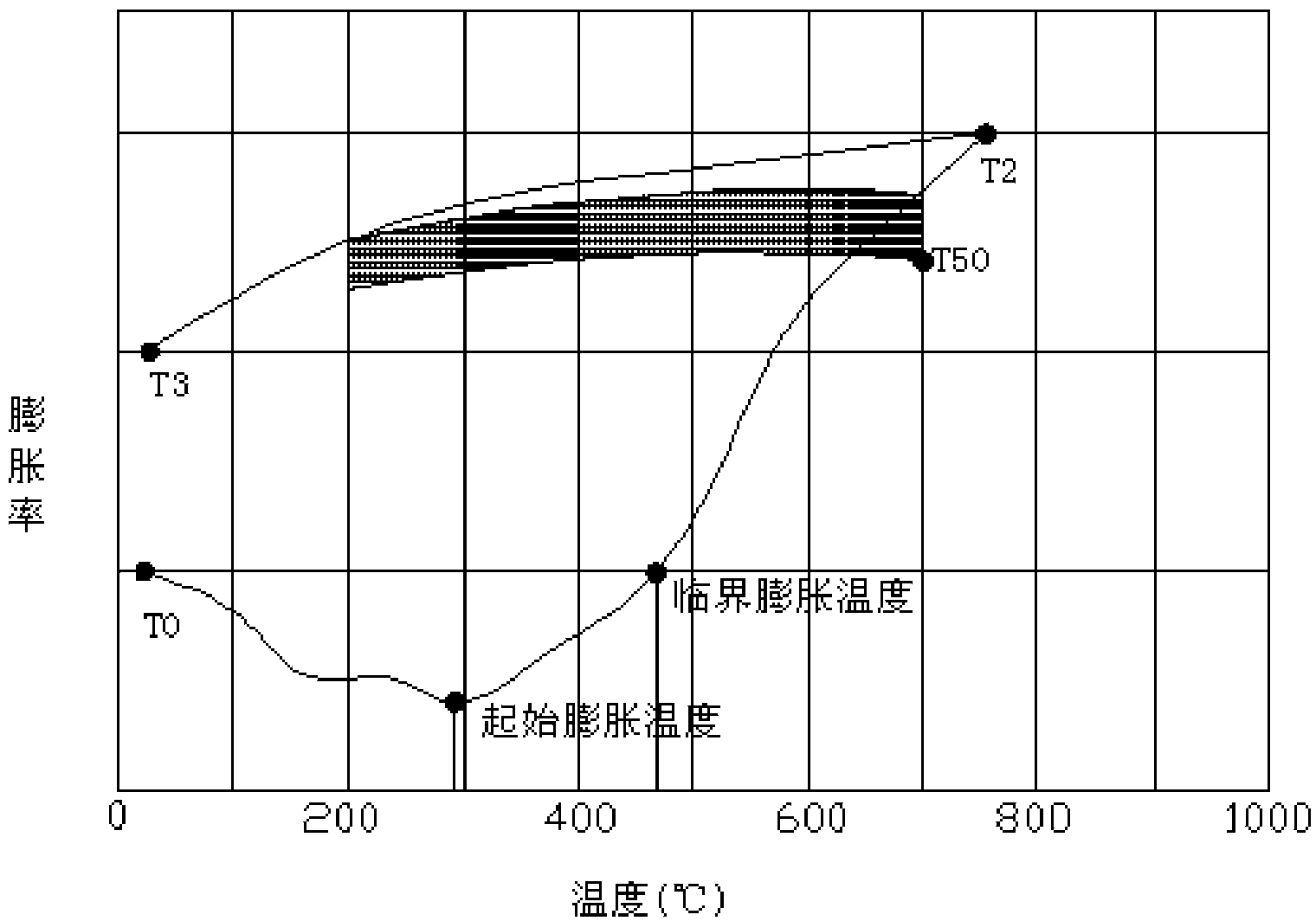

[0041] (4) Sample data detection. After the sample is placed, calibrate the zero position of the thermal expansion analyzer, then turn on the heating switch of the heating device in the thermal expansion analyzer, and raise the temperature at a heating rate of 15 / min until it reaches 750°C. The recording instrument in the mechanical analyzer records the data measured for the first time in the form of a schematic diagram of thermal expansion curve; when the temperature drops to room temperature, continu...

Embodiment 2

[0044] (1) Sampling, the selected gram weight is 4070g / m 2 , a piece of 100 × 100mm intumescent sealing gasket with a thickness of 6.02mm;

[0045] (2) Make a sample, use a die-cutting die to punch the intumescent sealing gasket into a test sample with a diameter of 11mm, and mark it as a 2# sample;

[0046] (3) put the sample, the 2# sample is placed below the movable end of the quartz glass rod in the thermal expansion analyzer, and a pressure of 1345g is provided above the quartz glass rod;

[0047] (4) Sample data detection. After the sample is placed, calibrate the zero position of the thermal expansion analyzer, then turn on the heating switch of the heating device in the thermal expansion analyzer, and raise the temperature at a heating rate of 15 / min until it reaches 750°C. The recording instrument in the mechanical analyzer records the data measured for the first time in the form of a schematic diagram of thermal expansion curve; when the temperature drops to room te...

Embodiment 3

[0050] (1) Sampling, the selected gram weight is 5200g / m 2 , a piece of 100×100mm expandable sealing gasket with a thickness of 7.65mm;

[0051] (2) Make a sample, use a punching die to cut the expansive sealing gasket into a test sample with a diameter of 11mm, and mark it as a 3# sample;

[0052] (3) put the sample, the 3# sample is placed below the movable end of the quartz glass rod in the thermal expansion analyzer, and a pressure of 1345g is provided above the quartz glass rod;

[0053] (4) Sample data detection. After the sample is placed, calibrate the zero position of the thermal expansion analyzer, then turn on the heating switch of the heating device in the thermal expansion analyzer, and raise the temperature at a heating rate of 15 / min until it reaches 750°C. The recording instrument in the mechanical analyzer records the data measured for the first time in the form of a schematic diagram of thermal expansion curve; when the temperature drops to room temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com