Gating system for cylinder cover of single-cylinder air cooled engine

An air-cooled engine and engine cylinder head technology, applied in casting molding equipment, casting molds, cores, etc., can solve the problems of difficult cylinder head core feeding, shrinkage, shrinkage, and porosity, and reduce consumption and shrinkage. The effect of reducing porosity and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

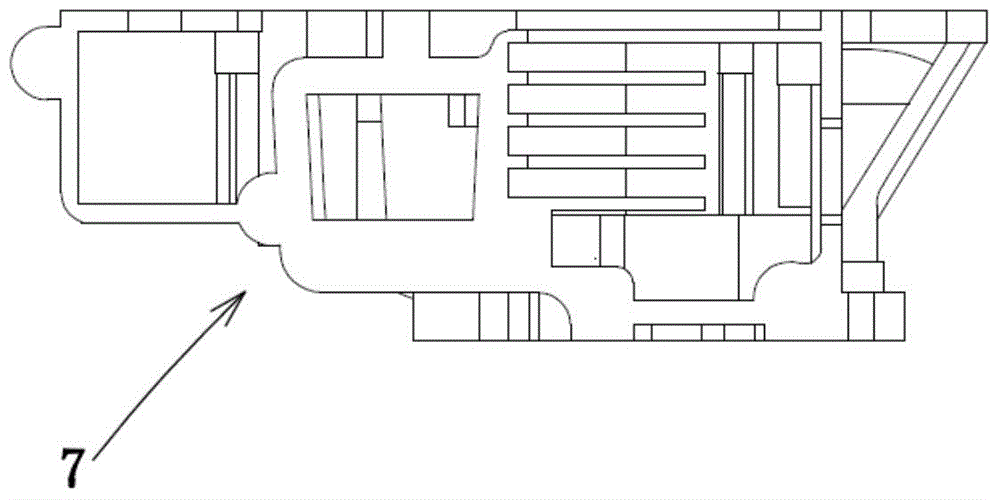

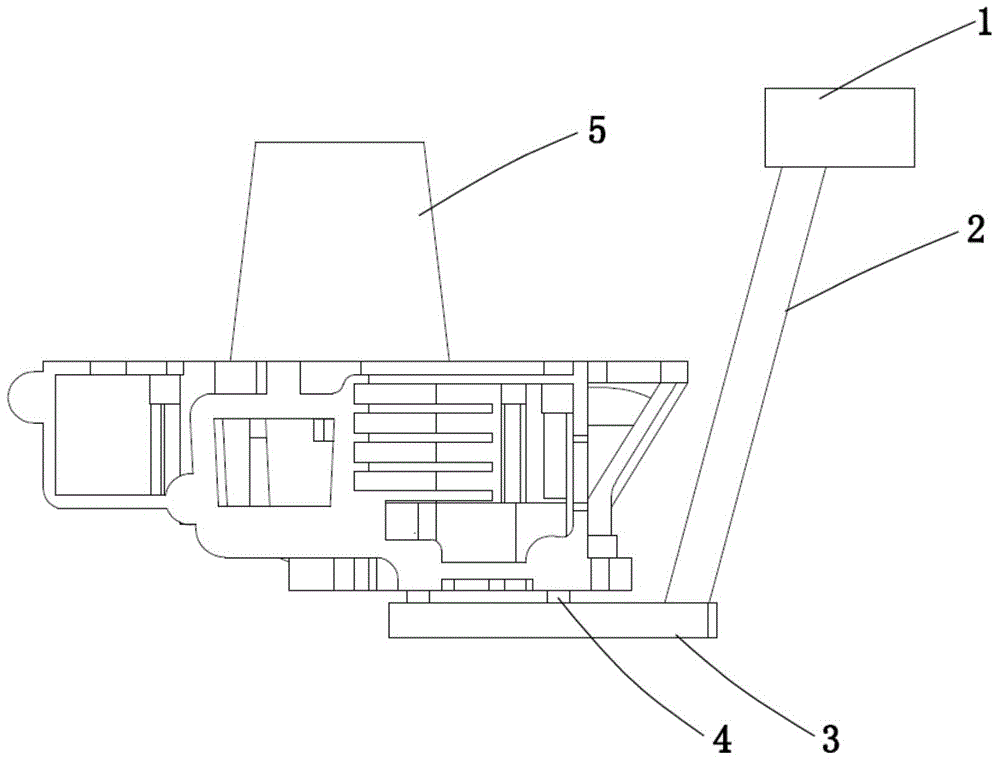

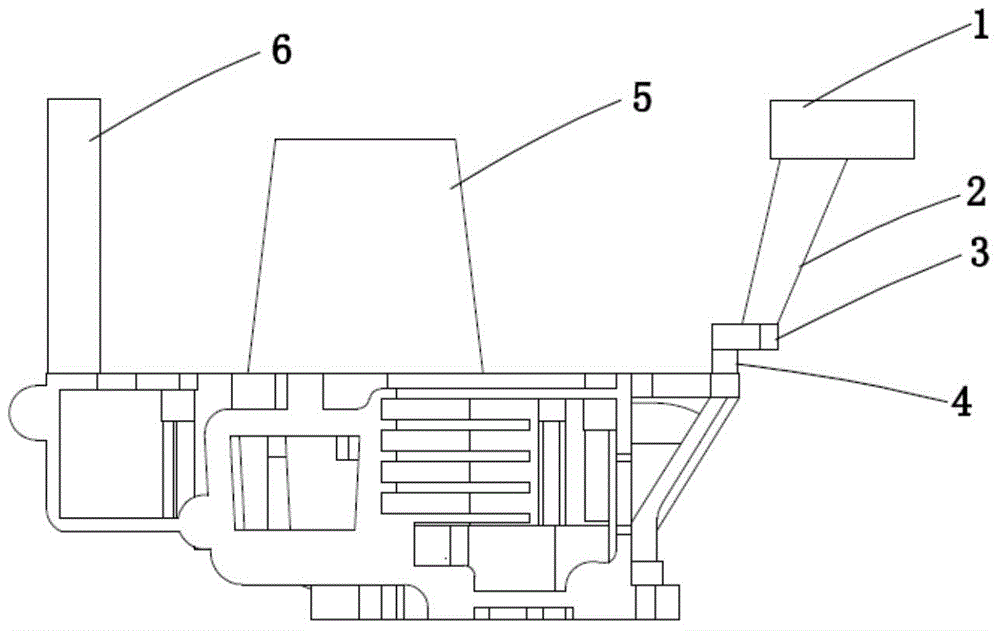

[0017] Embodiment: the gating system of the single-cylinder air-cooled engine cylinder head of this embodiment, such as figure 1 , 3 As shown, the top of the pouring mold of the engine cylinder head 7 is provided with a hidden riser 5 communicating with the cavity. 4. The sprue 3, the sprue 2 and the sprue cup 1 are sequentially arranged on the sprue; the alumina ceramic tube 6 connected to the mold cavity and the external atmosphere is provided on the top of the other end of the mold away from the sprue. Atmospheric energy enters the mold cavity through the alumina ceramic tube, which can realize smooth filling and effective feeding of castings. Figure 3-5 As shown, the cavity of the sprue 2 shrinks gradually from top to bottom. In the specific structural setting, the upper and lower end faces of the sprue are as follows Figure 4 , 5 As shown, that is, the cross-sectional length of the sprue remains unchanged, and the cross-sectional width decreases gradually.

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com