A kind of production equipment of latex pad

A production equipment and latex technology, applied in the field of latex pad production equipment, can solve the problems of inability to meet market demand, latex pads have not achieved assembly line production, low production efficiency, etc., to achieve good market prospects, no harmful components, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

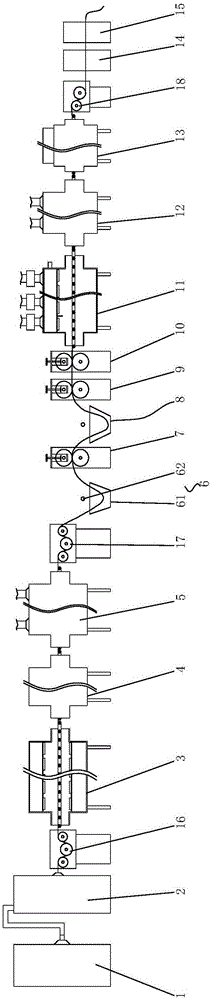

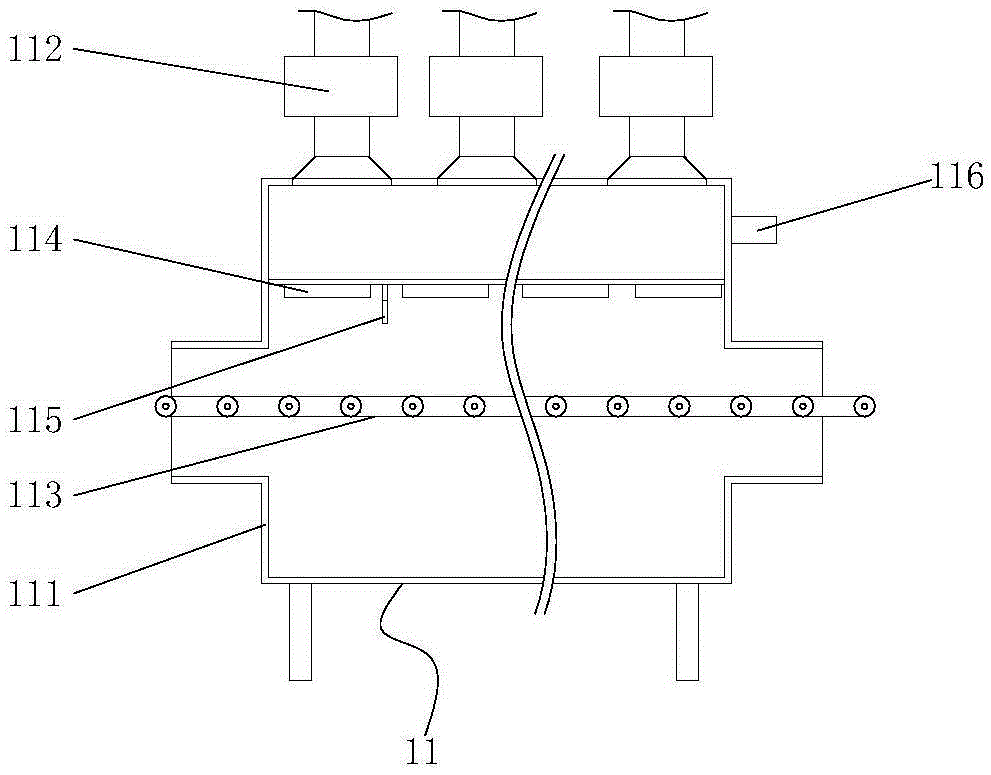

[0020] Such as Figure 1 to Figure 4 As shown in one of them, the production equipment of a kind of latex mat of the present invention, it comprises foaming machine 1, extrusion molding machine 2, ultraviolet ray sterilization setting machine 3, dry steamer 4, the first steam dryer 5 successively along the assembly line direction , washing device 6, two or more extrusion roller groups 7, 9, 10, microwave dryer 11, second steam dryer 12, cooling machine 13, punching machine 14 and cutting machine 15;

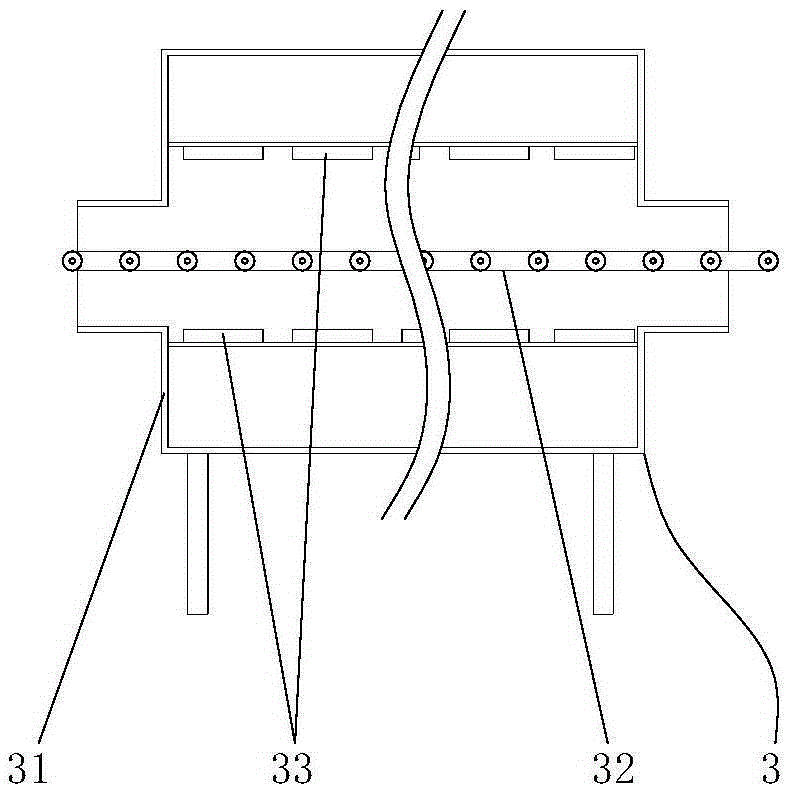

[0021] Described ultraviolet sterilizing and setting machine 3 comprises tunnel type sterilization case 31, and one end of sterilization case 31 is provided with entrance, and the other end is provided with exit, is provided with the sterilization conveying net belt 32 that runs through its entrance and exit in the sterilization case, the sterilization conveying net Several ultraviolet germicidal lamps 33 are arranged at equal intervals above and below the belt 32;

[0022] Desc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com