Oil and gas field drilling fluid sludge treatment method

A sludge treatment and drilling fluid technology, applied in the fields of sludge treatment, water/sludge/sewage treatment, mining wastewater treatment, etc., can solve the problem that the environmental protection measures of the sludge tank are difficult to maintain and protect, increase the cost of environmental protection treatment, and endanger the surrounding environment. and other problems, to achieve the effect of small footprint, high degree of automation and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0049] 1. System

[0050] 1. Overall

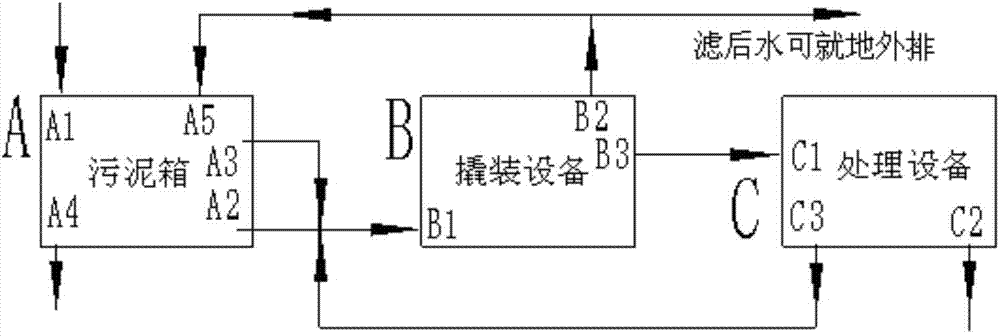

[0051] Such as figure 1 , this system includes skid-mounted equipment B (ZL201210145000.1) and processing equipment C (ZL 201310493396.3):

[0052] Set up with sludge tank A:

[0053] Sludge tank A, skid-mounted equipment B and treatment equipment C are connected in sequence;

[0054] The sludge tank A is a square box without a cover, 14m long, 3m wide, and 3.4m high; in the sludge tank A, there are drilling fluid inlet A1, drilling fluid sewage outlet A2, flushing water outlet A3, 1# The sludge outlet for cleaning and treatment (the treated sludge can be landfilled on site) A4 and the filtered water reuse inlet A5;

[0055] In the skid-mounted equipment B, there are drilling fluid sewage inlet B1, filtered water outlet (the filtered water can be directly discharged or used as reused clean water for cleaning 1# sludge) B2 and 2# sludge outlet B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com