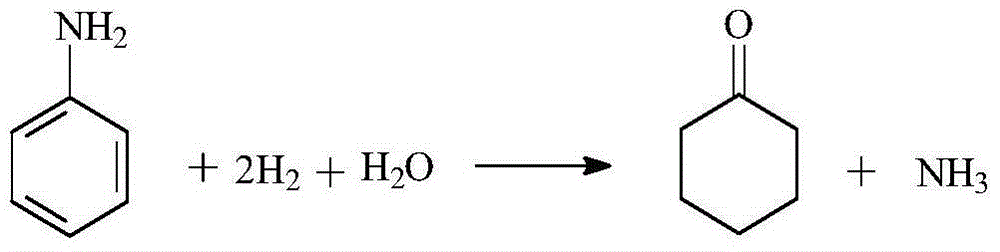

Method for directly synthesizing cyclohexanone by hydrogenation of aniline

A technology of cyclohexanone and aniline, applied in the field of chemical technology, can solve the problems of high production cost, low efficiency of cyclohexene, complicated process route, etc., and achieves the effects of cheap and easy-to-obtain aniline, mild reaction conditions and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the autoclave, add aniline 0.37g successively, the Pd / MCM-41 (molecular sieve) catalyst 0.78g that loading capacity is mass percent 2%, AlCl 3 N 2 Make a replacement. Then raise the temperature to 80°C, and then feed hydrogen to the reaction pressure of 1.3MPa and keep it. After 1 hour of reaction, stop the hydrogen flow, cool down to room temperature, and filter and separate the catalyst and the reaction solution under reduced pressure. The reaction solution is extracted and separated by toluene to obtain an organic phase. , and the organic phase was analyzed by gas chromatography. The yield of the product cyclohexanone was quantitatively calculated to be 56.4%.

Embodiment 2~5

[0035] The same operation steps and reaction conditions as in the process of synthesizing cyclohexanone in Example 1, the active metals of the catalyst were changed to Ru, Rh, Pt, Au respectively. The organic phase was analyzed by gas chromatography, and the yield of the product cyclohexanone was quantitatively calculated. The experimental results are shown in Table 1.

[0036] The impact of table 1 catalyst active metal on the synthetic cyclohexanone reaction

[0037] Example

Embodiment 6~10

[0039] The operating steps and reaction conditions of the synthetic cyclohexanone process in Example 1 are the same, and the carrier of the catalyst is changed to AC, γ-Al 2 o 3 , TS-1, HZSM-5, SBA-15, etc. The organic phase was analyzed by gas chromatography, and the yield of the product cyclohexanone was quantitatively calculated. The experimental results are shown in Table 2.

[0040] The impact of table 2 catalyst carrier on the synthetic cyclohexanone reaction

[0041] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com