A method for forging and extruding rod body aggregate type centralizing sucker rod

An extrusion method and sucker rod technology, which are used in drill pipes, earth-moving drilling, drilling equipment, etc., can solve the problems of easy slipping and falling off, accelerated oil pipe wear, and poor positioning, and achieve the effect of solving slipping and falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically introduced below in conjunction with the drawings and specific embodiments, in which the selection of materials and processing techniques known to those skilled in the art will not be repeated.

[0026] First, a forging and extrusion method for rod body aggregate type righting sucker rod of the present invention is introduced.

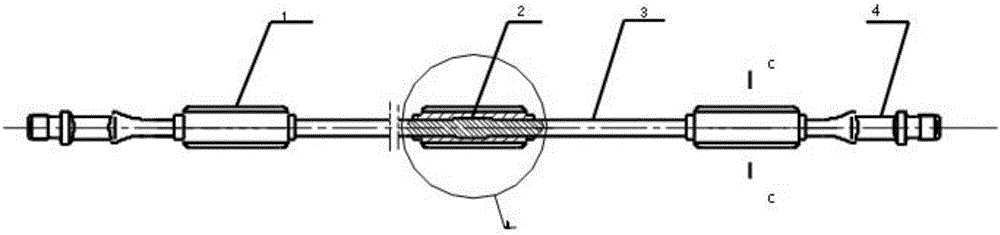

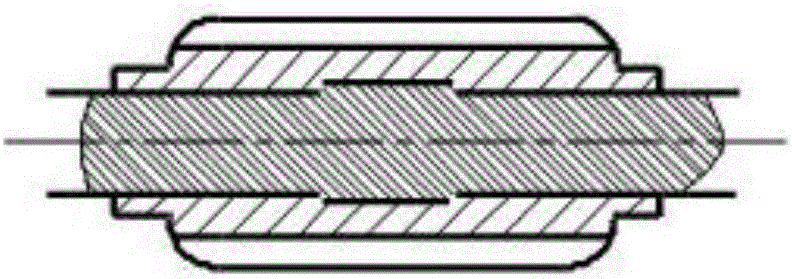

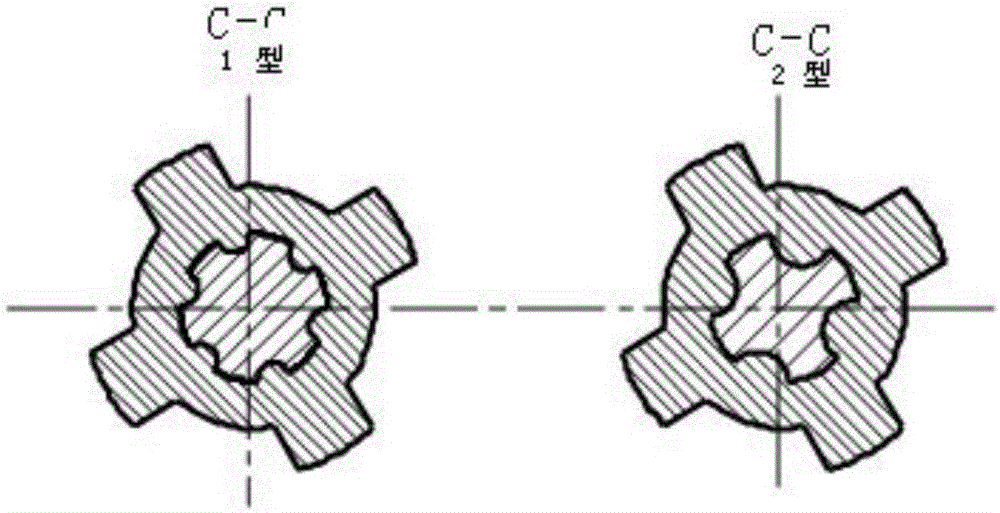

[0027] Reference Figure 1-3 , The method for casting a rod body aggregate type righting sucker rod of the present invention is characterized in that it comprises the following steps:

[0028] The first step is to straighten the raw material of the forged and extruded sucker rod.

[0029] The materials used for forging and extruding sucker rods are mainly divided into steel and non-metallic materials: steel can be used such as: 45 steel, 35Mn 2 , 40Mn 2 , 20CrMo, 30CrMo, 40CrMnMo, 35CrMo, 42CrMo, 16Mn 2 SiCrMoVTiA; non-metallic materials can use glass fiber reinforced plastic and carbon fiber composite materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com