Glass fiber cloth secondary sizing drying device

A technology of glass fiber cloth and drying equipment, which is applied in the field of drying boxes, and can solve problems such as difficult removal, tight warp, and low drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

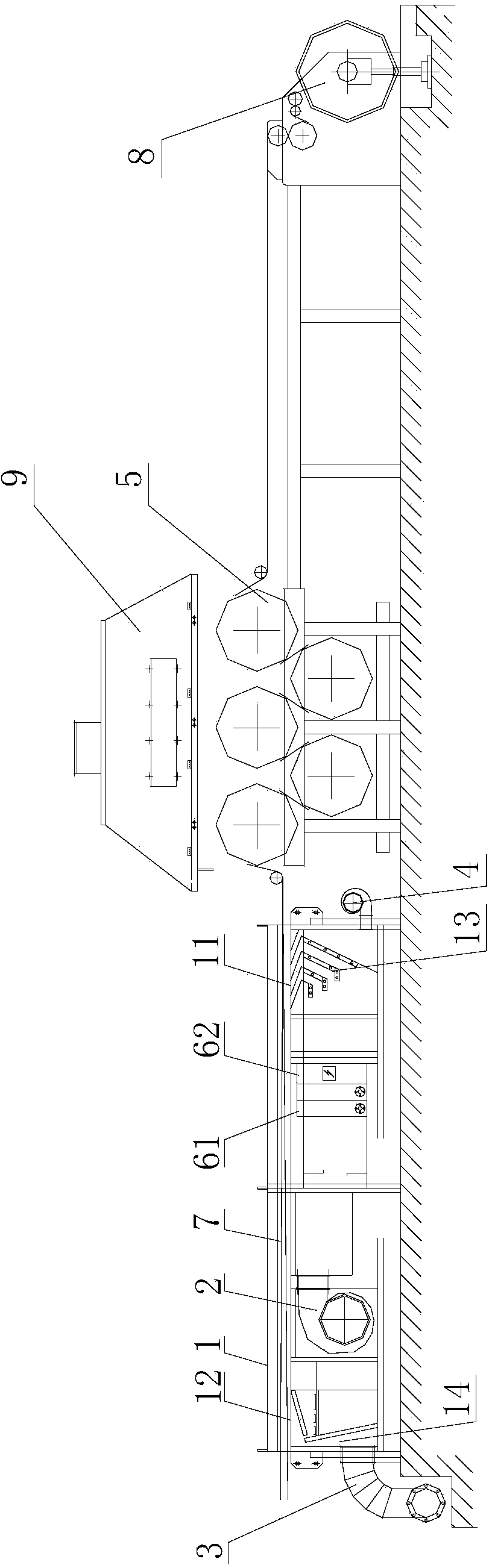

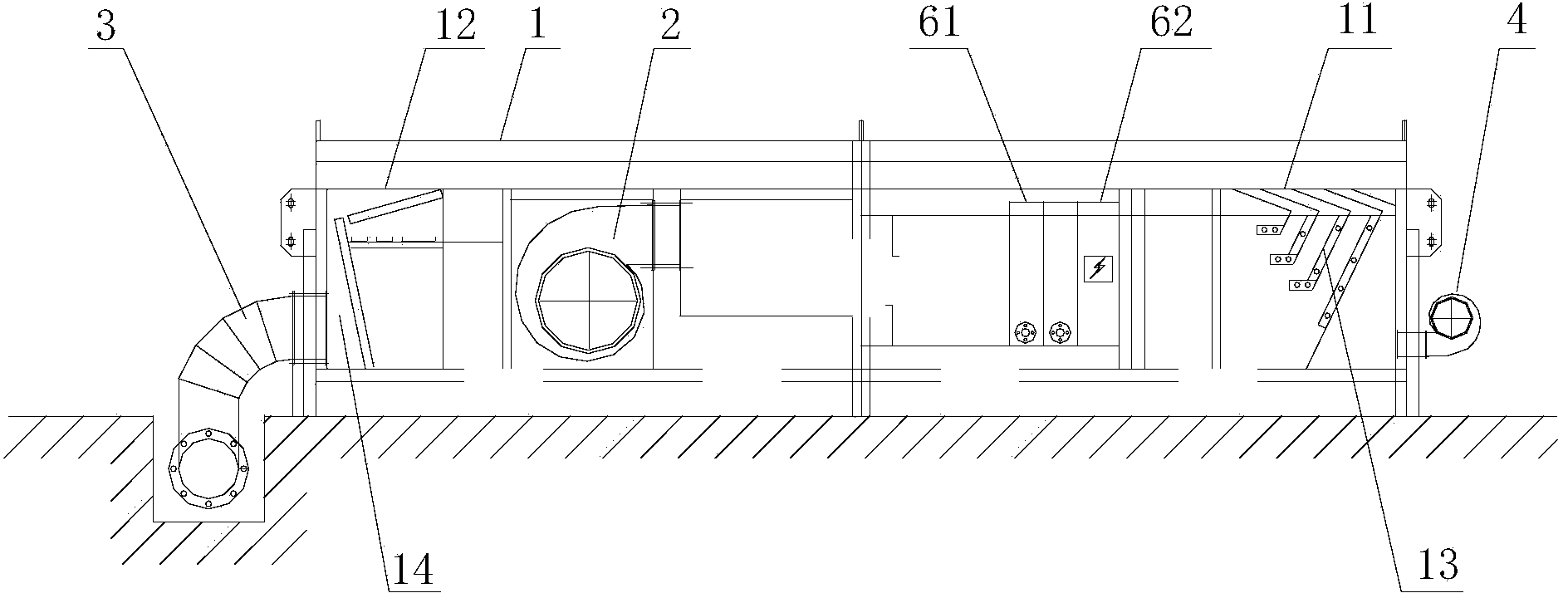

[0019] Such as figure 1 , figure 2 As shown, the glass fiber cloth secondary sizing and drying equipment includes a primary drying device and a secondary drying device. The primary drying device includes a drying box 1, an air supply device 2, a heating device, an exhaust device 3 and The cooling device 4 and the drying box 1 are divided into two layers arranged up and down, and the air supply device 2 and the heating device are arranged on the lower layer of the drying box 1; the two sides of the bottom of the upper layer of the drying box 1 are respectively provided with air inlets for air intake 11 and the air outlet 12 for air outlet; the air source sent by the air supply device 2 is converted into hot air by the heating device and enters the upper layer of the drying box 1 from the air inlet 11 to dry the product, and the hot air finally removes the moisture on the product Take out and discharge from the air outlet 12; the exhaust device 3 is arranged on the side corres...

Embodiment 2

[0024] The rest are the same as the above-mentioned embodiment, the difference is that, as figure 2 As shown, the air inlet 11 is correspondingly provided with an air inlet guide channel 13, and the air inlet guide channel 13 is first arranged obliquely along the upper right, which is equivalent to a buffer channel, and then is folded along the upper left at an acute angle to finally connect to the air inlet 11, which is equivalent to In the acceleration channel, it can effectively improve the drying speed of the product. The air outlet 12 is correspondingly provided with an air outlet guide channel 14, and the air outlet guide channel 14 is connected to the air exhaust device 3, so that excess water can be discharged smoothly.

Embodiment 3

[0026] The rest is the same as the above embodiment, the difference is that the hot air inlet direction is set opposite to the product conveying direction, such setting improves the drying efficiency of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com