Ground wire-free non-conductive coating electric spark detection device and detection method thereof

A non-conductive, ground-free technology, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as coating failure, friction and wear between wires and coatings, and reduce the coating thickness on the inner surface of the pipe. Achieve the effect of avoiding wear and reducing power demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

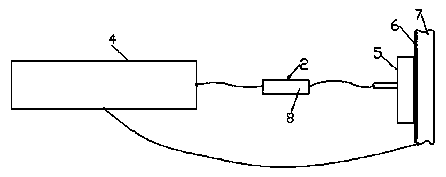

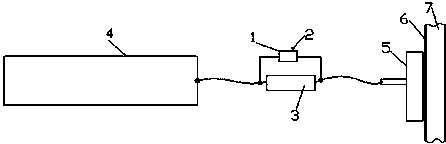

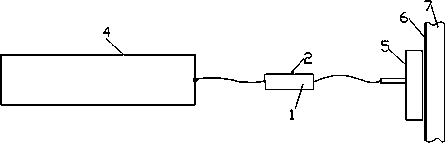

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Referring to Fig. 2, a kind of electric spark detection device without ground wire non-conductive coating includes a pulse high voltage generator 4 arranged on a trolley, the pulse high voltage generator 4 is connected in series with a voltage dividing resistor 3 and a copper wire brush 5, and the A high-frequency signal acquisition and processing device 1 is arranged on both sides of the piezoresistor 3, and the high-frequency signal collection and processing device 1 is connected to the alarm 2; the copper wire brush 5 moves on the coating 6 of the metal substrate 7.

[0019] A non-ground wire non-conductive coating electric spark detection method, comprising the following steps:

[0020] 1) To detect the voltage signal, the specific method is:

[0021] Make the pulse high voltage generator 4, the voltage dividing resistor 3 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com