A method for preparing a sample for gas chromatographic analysis of tobacco components and a method for gas chromatographic analysis of tobacco components

A gas chromatographic analysis and gas chromatographic technology, applied in the field of tobacco component analysis, can solve the problems of loss of volatile aroma components, decrease in accuracy, and influence on tobacco leaf components, etc., and achieve the effect of improving detection sensitivity and separation, and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

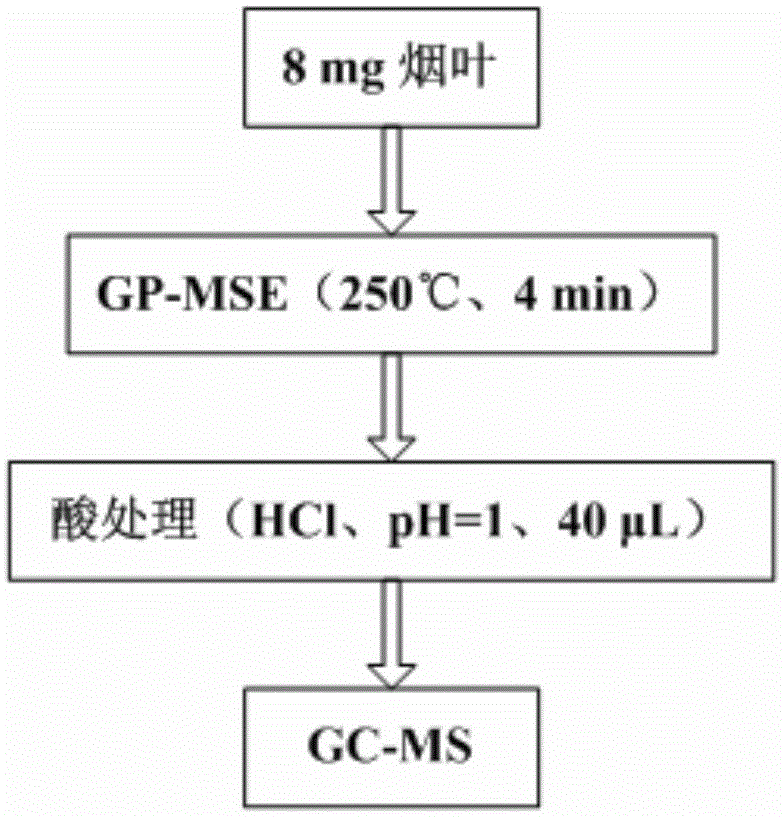

[0046] The invention provides a method for preparing a tobacco component gas chromatographic analysis sample, comprising the following steps:

[0047] The tobacco sample to be tested is subjected to air-purging micro-extraction to obtain the extract phase. The temperature of the air-purging micro-extraction is 240°C to 260°C, the time of the air-purging micro-extraction is 3min to 5min, and the airflow is The extraction solvent of scanning micro-extraction is n-hexane;

[0048] The extraction phase is mixed with hydrochloric acid solution, and liquid-liquid extraction is carried out to obtain an organic phase;

[0049] The water in the organic phase is removed to obtain a gas chromatography analysis sample of tobacco components.

[0050] The method provided by the present invention adopts n-hexane as the extraction solvent, and carries out air purging micro-extraction on the tobacco sample to be tested at 240°C to 260°C for 3min to 5min; then mixes the obtained extraction pha...

Embodiment 1

[0083] The tobacco leaf sample that this embodiment detects is the middle leaf of flue-cured tobacco, and grade is B 2 F, tobacco leaves before processing and after conditioning;

[0084] Freeze-dry the tobacco leaves and pulverize them with a pulverizer. After passing through a 60-mesh sieve, put the fraction under the sieve into a brown sample bottle and store it at -4°C for future use.

[0085] Accurately weigh 5 tobacco leaf samples of 8 mg each, put them into sample tubes, put the sample tubes into the sample pool, seal the mouth of the sample pool with a septum, place the 200 μL inner tube on the support frame of the condenser, and use The PTFE tube is connected with two needles, one end is put into the 200μL inner tube until it just reaches the bottom of the liner, the other end is inserted into the sample cell along the sealing gasket until it just passes through the lower part of the sealing gasket, and the 200μL liner Add about 100 μL of n-hexane extraction solvent ...

Embodiment 2

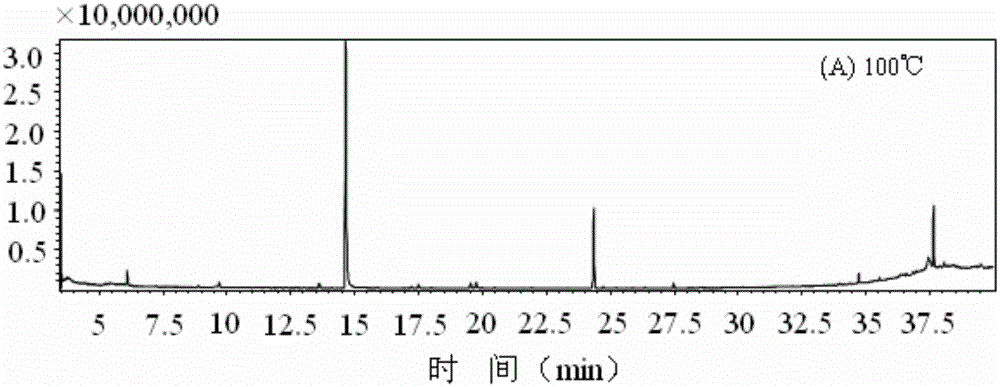

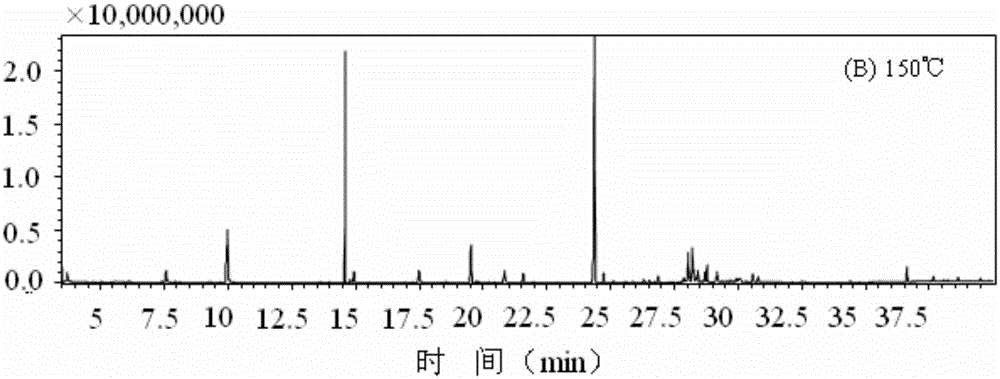

[0098] Gas chromatography-mass spectrometry analysis was carried out on the tobacco leaf sample by using the technical scheme of Example 1. The difference is that the temperature of the micro-extraction in this application is 250° C., and the time of the micro-extraction is 3 min, 4 min and 5 min respectively.

[0099] The result is as Figure 7-9 as shown, Figure 7 The micro-extraction time that the embodiment of the present invention 2 obtains is the chromatogram of 3min, Figure 8 The micro-extraction time that the embodiment of the present invention 2 obtains is the chromatogram of 4min, Figure 9 The micro-extraction time that obtains for the embodiment 2 of the present invention is the chromatogram of 5min. Depend on Figure 7-9 It can be seen that when the micro-extraction time is 4 minutes, the types and quantities of aroma components are the largest.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com