Facility tomato supplemental lighting adjustment and control method and system based on growth model

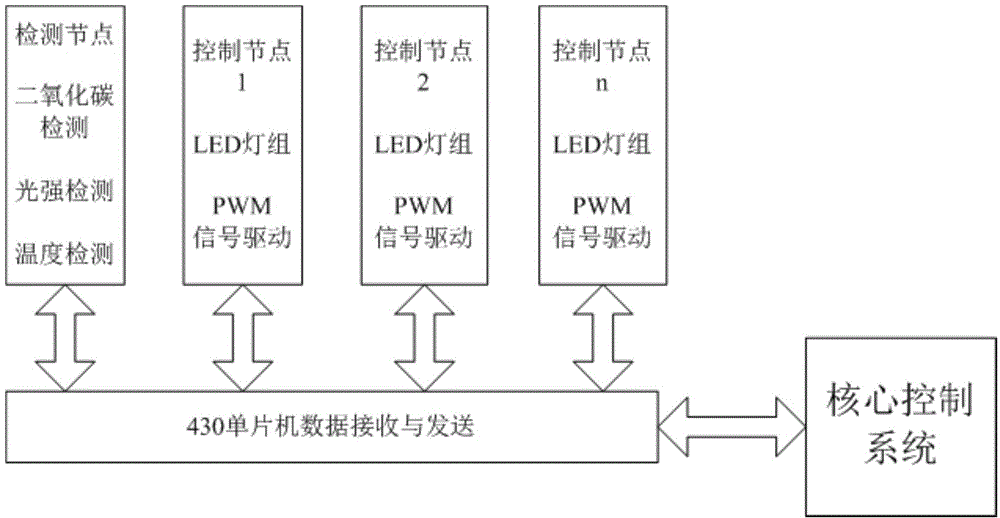

A growth model and control system technology, applied in the agricultural field, can solve problems affecting crop yield and quality, poor scalability, difficult deployment and maintenance, etc., to achieve modern management and precise operation, improve yield and quality, and overcome the amount of supplementary light Insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

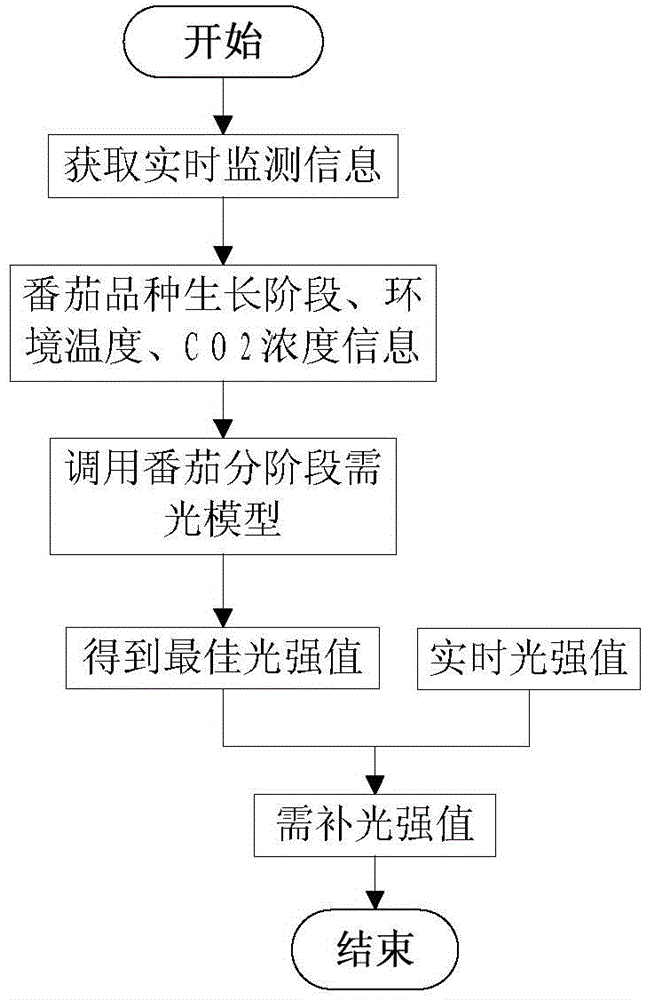

Method used

Image

Examples

specific Embodiment

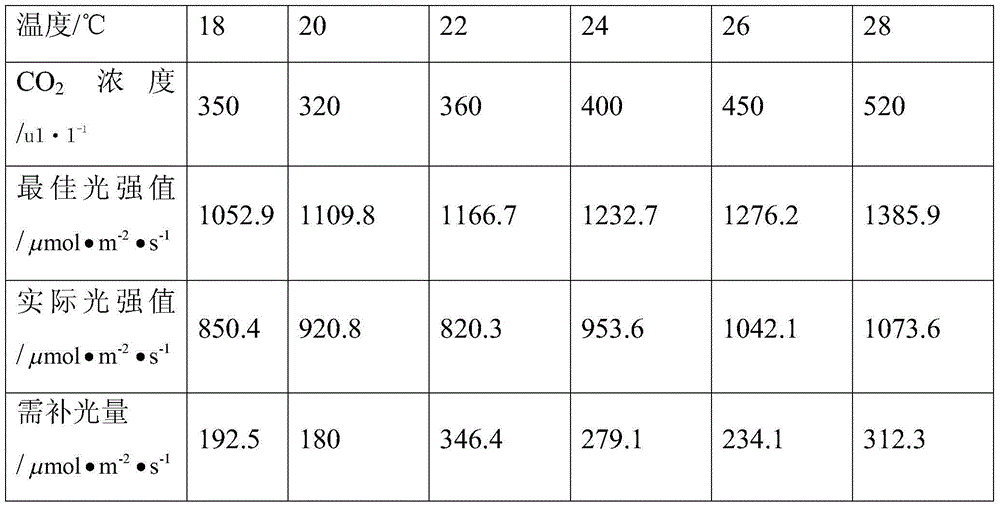

[0029] A specific example of model establishment provided by the present invention is as follows:

[0030] Three typical long-fruited, prismatic and apple-shaped tomato research objects were selected, and healthy tomatoes were selected for experiments through seedling cultivation in the greenhouse. Use the Li-6400xt portable photosynthesis measurement system to control the temperature, carbon dioxide concentration and light intensity, so as to obtain the light response curve under different temperature and carbon dioxide concentration. The light intensity gradient of the light response curve is set to 0, 10, 30, 50, 100, 200, 300, 500, 700, 1000, 1200, 1500, 2000mmol m -2 ·s -1 , the temperature gradient is set to 16, 19, 22, 25, 28, 31, 34, 37, 40°C, the carbon dioxide concentration gradient is 300, 400, 500, 600, 700, 800, 900, 1000, 1100, 1200, 1300, 1500μmol·m -2 ·s -1 , and each experiment was repeated three times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com