A kind of drying method of organic edible flowers

An edible flower and organic technology, applied in the direction of preserving fruits/vegetables through dehydration, etc., can solve problems such as difficulty in reaching organic standards, affecting the quality of edible flowers, and difficult real-time monitoring, etc., to improve appearance, improve drying effect, and facilitate monitoring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of drying method of organic edible flowers of the present embodiment comprises the following steps:

[0036] 1) The picked organic chrysanthemums are graded and selected, and then arranged manually;

[0037] 2) Heat pump drying: It is carried out in three stages. The first stage: slow drying at low temperature and high humidity for 1 hour, to preserve the quality of the organic chrysanthemum itself to the greatest extent; the second stage: gradually raising the temperature and lowering the humidity and drying for 8 hours, while ensuring product quality. At the same time, speed up the drying rate; the third stage: drying at high temperature and low humidity for 3 hours to maximize the drying rate and save energy; the drying parameters of the heat pump are shown in Table 5;

[0038] Table 5 Parameter setting of heat pump drying (1)

[0039]

[0040] 3) The dried organic chrysanthemums are graded and selected again according to their quality, and then packaged s...

Embodiment 2

[0045] A kind of drying method of organic edible flowers of the present embodiment comprises the following steps:

[0046] 1) After the picked organic okra flowers are graded and selected, impurities and incomplete okra flowers are removed and placed on a plate manually;

[0047] 2) Heat pump drying: It is carried out in three stages. The first stage: slow drying at low temperature and high humidity for 1 hour, to preserve the quality of the organic okra flowers to the greatest extent; the second stage: gradually increase the temperature and reduce humidity and dry for 8 hours, in order to ensure the quality of the product While improving the quality, speed up the drying rate; the third stage: drying at high temperature and low humidity for 3 hours to maximize the drying rate and save energy; the drying parameters of the heat pump are shown in Table 6:

[0048] Table 6 Parameter setting of heat pump drying (2)

[0049]

[0050] 3) The dried organic okra flowers are graded ...

Embodiment 3

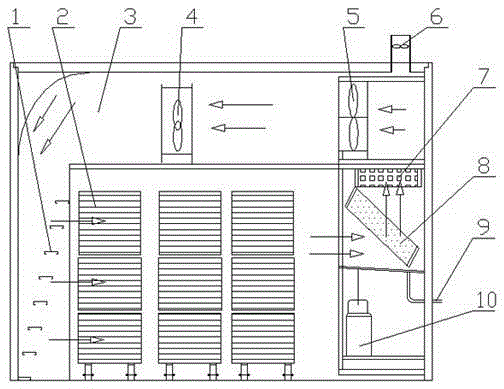

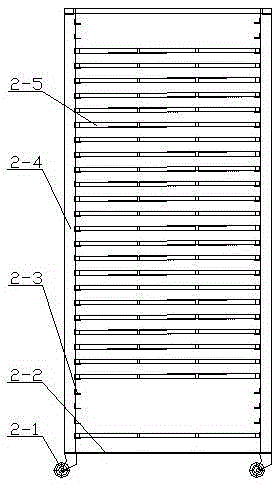

[0054] refer to figure 1 and figure 2 , a method for drying organic edible flowers of the present embodiment, comprising the following steps:

[0055] 1) The picked organic chrysanthemums are graded and selected, and then arranged manually;

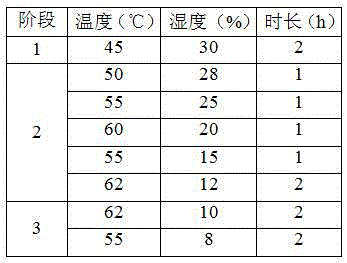

[0056] 2) Heat pump drying: It is carried out in three stages. The first stage: slow drying at low temperature and high humidity for 1 hour, to preserve the quality of the organic chrysanthemum itself to the greatest extent; the second stage: gradually raising the temperature and lowering the humidity and drying for 8 hours, while ensuring product quality. At the same time, speed up the drying rate; the third stage: drying at high temperature and low humidity for 4 hours to maximize the drying rate and save energy; the drying parameters of the heat pump are shown in Table 7:

[0057] Table 7 Parameter setting of heat pump drying (3)

[0058]

[0059] 3) The dried organic chrysanthemums are graded and selected again according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com