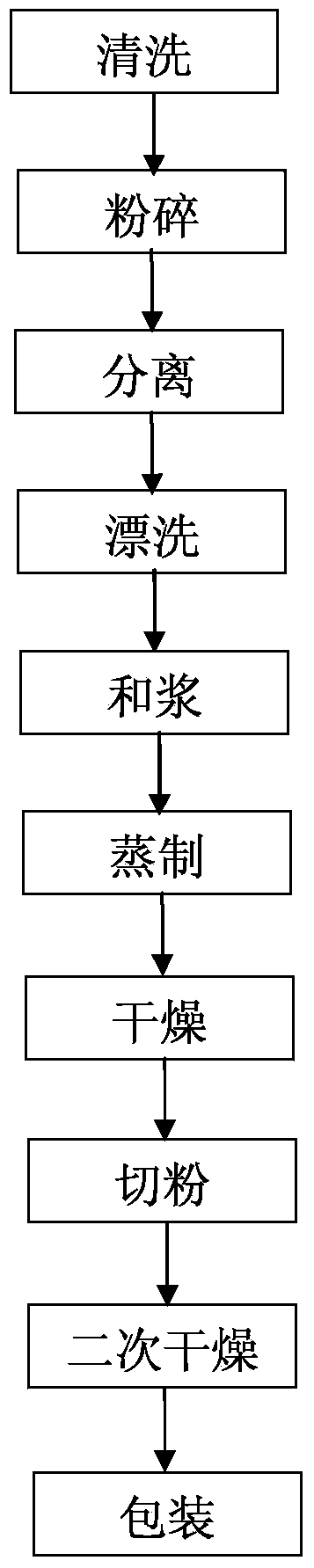

Production process for dried lotus root vermicelli

A production process and vermicelli technology, which is applied in food processing, food preparation, food drying, etc., can solve the problems of brittleness, lack of toughness, excessive raw powder, and high manual labor intensity, etc., and achieve a bright and tidy appearance, pure taste, and unique flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0030] Specific embodiment 1 after cleaning and pulverizing the dry lotus root of the raw material, obtain the used slurry through 350 purpose vibrating sieving bed separation, control the slurry concentration to be 18 Baume degree, put into the mold and steam, the temperature in the mold is 103 degrees, The first drying oven temperature is 55 degrees, and the drying time is 50 minutes, and then the electric guillotine is used to cut the powder according to the requirements, and then enters the second drying. The oven temperature is 65 degrees, and the drying time is 7 hours. After the drying is completed It can be measured and packaged.

specific Embodiment 2

[0031] Specific embodiment 2 after cleaning and pulverizing the dry lotus root as a raw material, separate the used slurry through a 325-purpose vibrating sieving bed, control the slurry concentration to be 21 degrees Baume, put it into a mold and steam it, and the temperature in the mold is 100 degrees. The temperature of the first drying oven is 58 degrees, and the drying time is 55 minutes. Then, the electric guillotine is used to cut the powder according to the requirements, and then enters the second drying. The temperature of the oven is 70 degrees, and the drying time is 7.5 hours. After the drying is completed It can be measured and packaged.

specific Embodiment 3

[0032] Specific embodiment 3 after cleaning and pulverizing the dry lotus root as raw material, obtain the used slurry through 400 mesh vibrating sieving bed separation, control the slurry concentration to be 20 Baume degree, put into the mold and steam, the temperature in the mold is 100 degrees, The first drying oven temperature is 65 degrees, and the drying time is 60 minutes. Then, the electric guillotine is used to cut the powder according to the requirements, and then enters the second drying. The oven temperature is 70 degrees, and the drying time is 8 hours. After the drying is completed It can be measured and packaged.

[0033] The rehydration time of the dried lotus root vermicelli products obtained in the above three examples is less than 5 minutes, and there is no obvious melting phenomenon for more than 12 minutes. There is no broken strips and draws, which has good edibility, and the product has good storage resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com